Mastering the Art of Industrial Beating Equipment Care

The hammer beater stands as a cornerstone in industrial processing, playing a vital role in material reduction and processing efficiency. Understanding proper maintenance techniques ensures optimal performance and longevity of these essential components. From manufacturing facilities to processing plants, the proper care of hammer beaters can make the difference between smooth operations and costly downtime.

Modern industrial processes rely heavily on the consistent performance of hammer beaters to maintain production standards and meet demanding schedules. The impact these components have on overall operational efficiency cannot be understated, making their maintenance a top priority for facility managers and maintenance teams alike.

Essential Maintenance Fundamentals

Regular Inspection Protocols

Implementing a systematic inspection routine for your hammer beater system is crucial for preventing unexpected failures. Daily visual checks should focus on wear patterns, unusual vibrations, and any signs of material buildup. Maintenance technicians should document any observations and track changes over time, creating a comprehensive maintenance history that can help predict potential issues before they escalate.

Weekly inspections should include more detailed examinations of the hammer beater assembly, including checking for proper clearances, bearing condition, and shaft alignment. This proactive approach helps identify developing problems early, allowing for scheduled maintenance rather than emergency repairs.

Cleaning and Wear Assessment

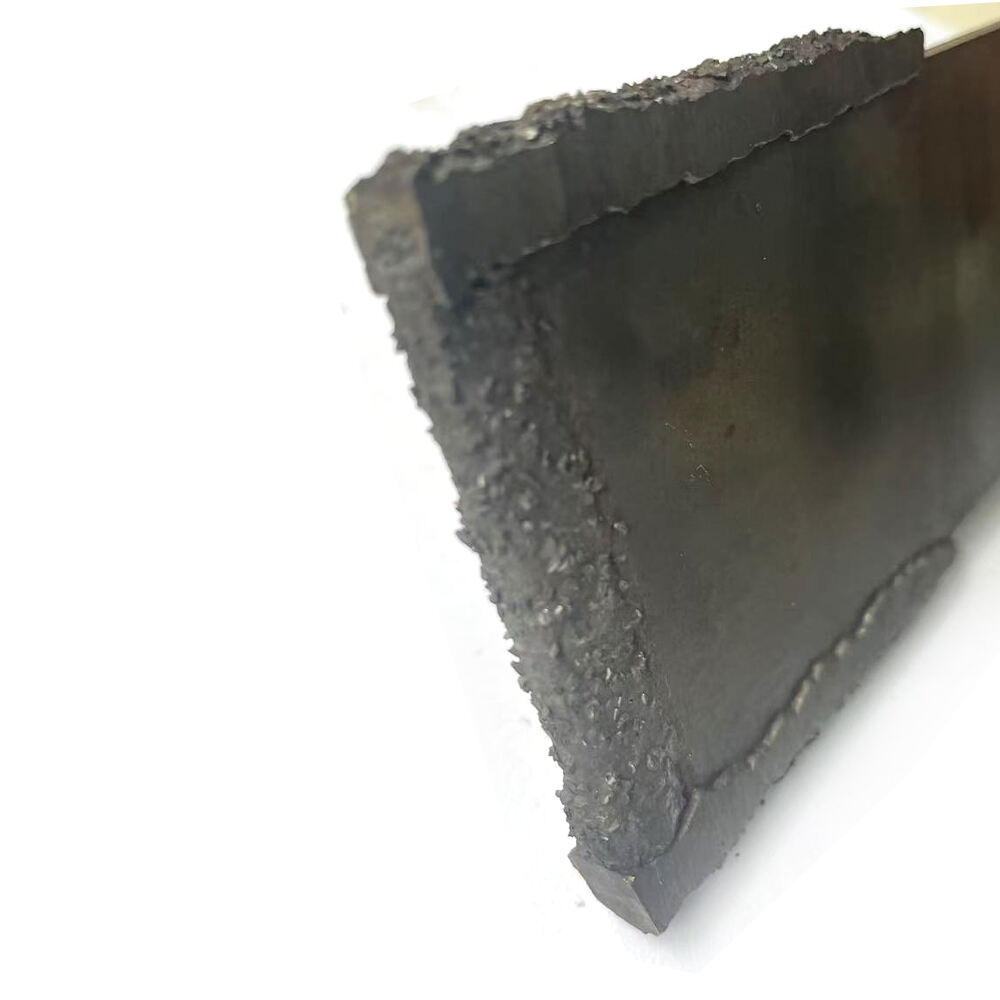

Regular cleaning of the hammer beater system prevents material buildup that can lead to imbalance and reduced efficiency. Proper cleaning techniques involve removing accumulated debris without damaging the equipment's surface. Using appropriate cleaning solutions and tools ensures the removal of stubborn materials while preserving the integrity of the hammer beater components.

Wear assessment requires careful measurement and documentation of component dimensions. Establishing baseline measurements and monitoring changes helps determine optimal replacement timing. This data-driven approach to maintenance prevents both premature replacement and excessive wear that could damage other system components.

Advanced Maintenance Strategies

Precision Alignment Techniques

Maintaining proper alignment of the hammer beater system is critical for optimal performance and longevity. Using modern laser alignment tools ensures precise positioning of all components. Regular alignment checks should be performed after any maintenance work and at scheduled intervals to prevent vibration issues and uneven wear patterns.

The alignment process must consider thermal expansion and operational conditions, making necessary adjustments to accommodate these factors. Proper documentation of alignment specifications and procedures ensures consistency across maintenance activities and shift changes.

Bearing Maintenance and Lubrication

The bearing system supporting the hammer beater requires special attention to prevent premature failure. Implementing a comprehensive lubrication program, including proper grease selection and application intervals, is essential. Temperature monitoring of bearings during operation can provide early warning of potential issues.

Regular analysis of bearing condition through vibration monitoring and oil analysis helps predict bearing life and plan replacements during scheduled downtimes. This predictive maintenance approach significantly reduces the risk of unexpected failures and extends equipment life.

Performance Optimization Methods

Operational Parameter Adjustment

Fine-tuning operational parameters maximizes hammer beater efficiency while minimizing wear. Speed, feed rate, and material consistency must be balanced to achieve optimal results. Regular monitoring and adjustment of these parameters ensure consistent performance and product quality.

Creating detailed operating procedures that specify acceptable parameter ranges helps operators maintain optimal conditions. This standardization improves consistency across shifts and reduces the risk of operator error affecting equipment performance.

Energy Efficiency Improvements

Modern hammer beater systems can benefit from various energy-efficiency improvements. Implementing variable frequency drives allows for better speed control and energy management. Proper maintenance of these systems, including regular calibration and monitoring, ensures optimal energy usage.

Energy consumption tracking and analysis can identify opportunities for efficiency improvements. This data helps justify equipment upgrades and modifications that can reduce operating costs while maintaining or improving performance.

Troubleshooting and Problem Resolution

Common Issues and Solutions

Understanding typical hammer beater problems and their solutions speeds up troubleshooting and reduces downtime. Vibration issues often indicate alignment problems or wear, while unusual noise may suggest bearing problems or loose components. Developing a systematic approach to problem identification and resolution improves maintenance efficiency.

Creating detailed troubleshooting guides that include common symptoms, potential causes, and recommended solutions helps maintenance teams respond quickly and effectively to issues. This knowledge base becomes an invaluable resource for training new technicians and maintaining consistent maintenance practices.

Emergency Response Procedures

Despite best maintenance practices, emergency situations may arise. Having well-documented emergency procedures ensures quick and appropriate responses to critical situations. These procedures should include safety protocols, shutdown procedures, and contact information for key personnel and support services.

Regular training and drills help maintenance teams stay prepared for emergency situations. This preparation includes maintaining an inventory of critical spare parts and ensuring necessary tools are readily available.

Frequently Asked Questions

How often should hammer beater components be replaced?

Component replacement intervals depend on various factors including operating conditions, material being processed, and usage patterns. Regular inspections and wear measurements should guide replacement decisions, typically ranging from 3-12 months for high-wear components.

What are the signs of a failing hammer beater system?

Common indicators include increased vibration, unusual noise, decreased processing efficiency, uneven wear patterns, and higher energy consumption. Regular monitoring helps detect these signs early, allowing for planned maintenance interventions.

How can hammer beater life be extended?

Extending service life involves proper alignment, regular cleaning, appropriate lubrication, monitoring operating parameters, and addressing issues promptly. Implementing a comprehensive preventive maintenance program is key to maximizing component longevity.

What safety precautions should be taken during maintenance?

Always follow lockout/tagout procedures, wear appropriate personal protective equipment, ensure proper ventilation, and use correct tools and procedures. Never perform maintenance while equipment is running, and always verify safety systems are functioning properly before returning equipment to service.