Professional contractors and DIY enthusiasts alike understand the importance of maintaining their tools in peak condition. Among all hand tools, hammers represent one of the most fundamental and frequently used instruments in construction, carpentry,...

VIEW MORE

Hammers represent one of humanity's oldest and most fundamental tools, serving countless applications across construction, manufacturing, craftsmanship, and household tasks. From the ancient stone hammers used by early civilizations to today's precis...

VIEW MORE

Selecting the right tool for your DIY project can make the difference between professional results and frustrating setbacks. Among the most fundamental tools in any workshop or toolbox, hammers serve as versatile instruments that have shaped human cr...

VIEW MORE

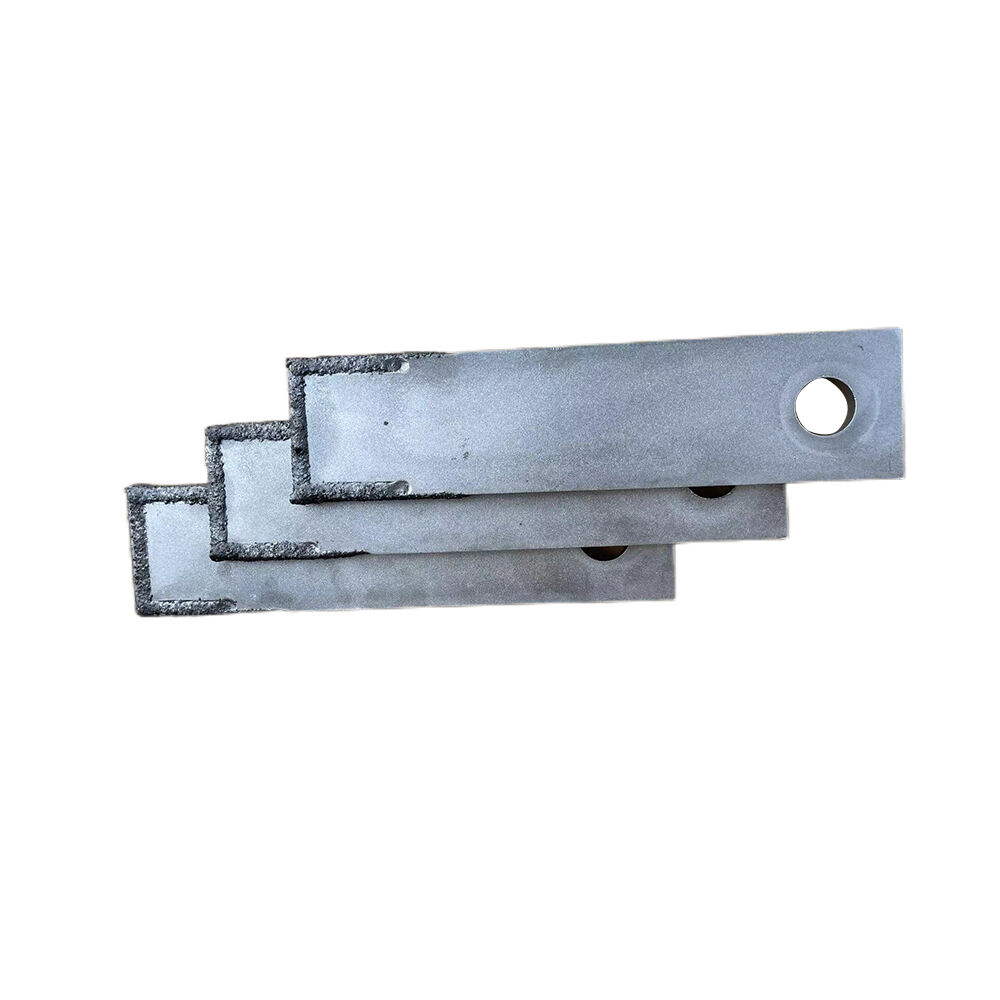

Industrial hammer operations require precision and reliability, making the selection of the right hammer blade a critical decision for manufacturing success. Whether you're involved in material processing, surface preparation, or heavy-duty demolitio...

VIEW MORE

Proper maintenance of industrial equipment components is crucial for operational efficiency and cost-effectiveness in manufacturing environments. The hammer blade represents one of the most critical wearing parts in crushing and grinding operations, ...

VIEW MORE

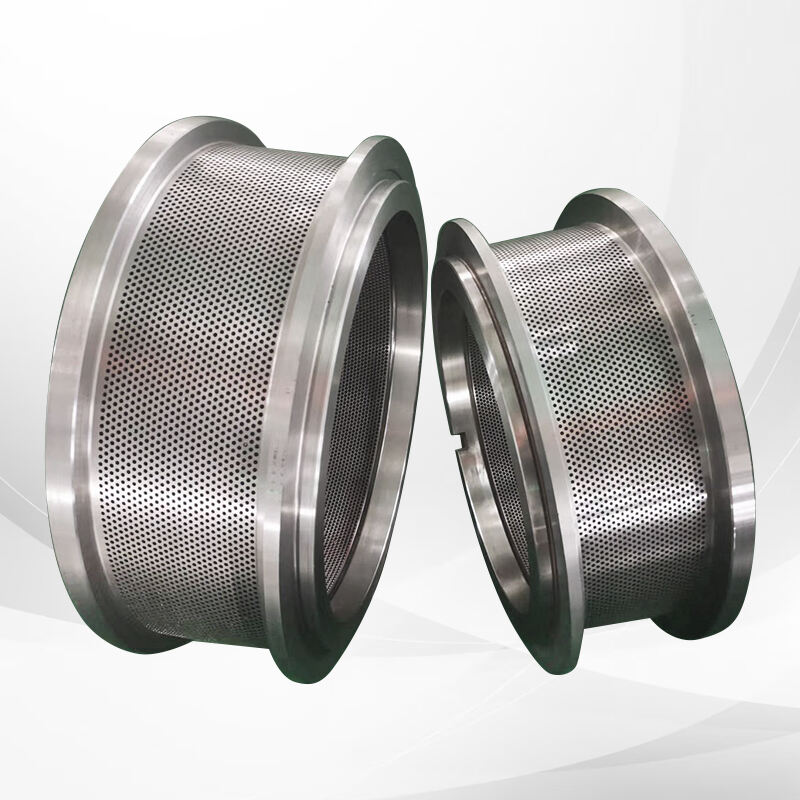

Selecting the appropriate hammermill beater for your industrial grinding operations requires careful consideration of multiple factors that directly impact performance, efficiency, and operational costs. A well-chosen hammermill beater can significan...

VIEW MORE

Proper maintenance of hammermill beater systems is crucial for maintaining optimal grinding performance and extending equipment lifespan in industrial operations. These robust components endure tremendous stress during high-speed material processing,...

VIEW MORE

Industrial crushing and grinding operations rely heavily on efficient machinery to process various materials effectively. The hammermill beater stands as one of the most critical components in modern material processing facilities, delivering consist...

VIEW MORE

In the world of industrial milling and crushing operations, choosing the right equipment can significantly impact production efficiency, operational costs, and final product quality. Two prominent technologies dominate the market: hammer beaters and ...

VIEW MORE

Industrial hammer beaters serve as critical components in various crushing and grinding applications across mining, construction, and material processing industries. These robust mechanical elements endure extreme operational conditions, making prope...

VIEW MORE

Maximizing Industrial Efficiency Through Premium Replacement Components The effectiveness of any industrial hammermill operation hinges significantly on the quality and reliability of its components. Selecting the right hammermill spare parts is not ...

VIEW MORE

Essential Guide to Maintaining Your Hammermill Equipment Keeping your hammermill operating at peak efficiency requires regular maintenance and timely replacement of worn hammermill parts. Whether you're managing a feed mill, recycling facility, or bi...

VIEW MORE