Maintaining Consistent Feed Rate for Optimal Grinding

The Importance of Steady Material Flow

Keeping the feed rate steady matters a lot when it comes to getting consistent particle sizes, something that directly affects product quality. If the material keeps flowing at the same pace, we avoid those annoying ups and downs that mess with grinding machines like hammer mills, causing them to either work too hard or not enough. Nobody wants their equipment struggling through inconsistent loads. A stable feed means better grinding results across the board. Industry data shows pretty impressive gains from this approach too, with some plants reporting around 20% improvements in production speed after fixing their flow issues. Real world examples back this up. For manufacturers looking to streamline operations, maintaining regular material flow isn't just about avoiding breakdowns it's actually a smart way to get reliable performance day after day while keeping product standards high.

Techniques to Stabilize Input Volumes

Stabilizing input volumes requires some clever approaches. Vibratory feeders work great alongside screw conveyors to keep things flowing at a steady pace throughout production runs. When manufacturers install automated monitoring systems, they get instant data that lets them tweak settings as needed, which helps everything run smoother day after day. Another trick is redesigning feed hoppers so materials don't pile up inside. This simple change makes sure nothing gets stuck and keeps the whole process running efficiently. Putting all these methods together gives companies much better control over their input volumes, which means more consistent output from their production lines. Automated feeding solutions have become pretty standard now, offering reliable ways to balance inputs while making grinding operations far more efficient overall.

Impact on Energy Efficiency and Output Quality

Keeping the feed rate steady really helps cut down on energy use, which means lower operating expenses over time. When the feed stays consistent throughout the process, the finished product tends to be better quality too. Less rework and fewer wasted materials naturally improves how productive the whole operation is. Energy audits have shown something interesting actually - when feed rates fluctuate, energy bills can jump as much as 15% higher than normal. That's a big hit to the bottom line. On the flip side, plants that manage to keep their feed rates stable just don't burn through as much power. There's definitely a connection between what goes in steadily and what comes out efficiently. For manufacturers running grinding operations, getting serious about controlling those feed rates pays off in two ways at once. Better energy savings plus higher quality products? That combination makes all the difference in staying profitable while still being environmentally responsible.

Strategic Screen Size Selection

Matching Screen Openings to Particle Requirements

Getting the screen size right matters a lot if we want to achieve proper particle sizes during grinding operations, especially when working with hammer mills. When mesh openings are sized correctly, they help sort materials better while keeping most of the fine particles intact, something that really affects how good the end product looks and performs. Industry experience shows that wrong screen sizes often result in poor grinding performance, slowing down production lines and creating all sorts of problems downstream. Screen selection isn't merely about making processes run smoother either. It actually determines whether finished products meet specifications or fall short of what customers expect. Many manufacturers have learned this the hard way after dealing with complaints about inconsistent material quality caused by improper screening choices.

Adjusting for Material Hardness Characteristics

Knowing how hard the material actually is plays a big role when picking the right screen size for processing. When dealing with tougher stuff, folks usually need those screens with smaller openings just to get decent grinding done. Most manufacturers warn against ignoring this factor because their experience shows that tough materials will wear out screens way faster than softer ones, which means spending extra money on fixes and new parts down the road. Adjusting screen sizes according to material hardness isn't only good for making sure equipment lasts longer though. It really affects what comes out at the end too. The grind won't be consistent if screens aren't matched properly, so operators end up wasting time and resources trying to fix problems that could have been avoided from the start.

Balancing Throughput and Fineness

Getting the right mix between how much material gets processed versus how fine the end product needs to be remains crucial for anyone running grinding operations. Most operators find that changing up screen sizes or adding extra screening steps helps them get finer results while still keeping production volumes decent. Some industry studies indicate these adjustments might boost overall productivity somewhere around 15%, though actual numbers vary depending on equipment quality. The truth is, when workers take time to tweak those screen sizes properly, it makes a real difference in day to day operations. Grinding plants stay efficient and profitable because they're not wasting resources chasing perfection at every stage of processing.

Incorporating strategic screen size selection across these parameters can enhance both the efficiency and productivity of grinding operations, ultimately supporting better output quality and process reliability.

Hammer-to-Screen Clearance Optimization

Measuring and Adjusting Critical Clearances

The space between hammers and screens inside a hammer mill makes all the difference when it comes to how well the grinding works. Getting these measurements right matters a lot, which is why many operators grab their calipers and feeler gauges regularly. When set properly, this gap helps balance power usage against actual results from the grinding process. From what we've seen in the field, leaving too much room between components just wastes electricity while producing subpar output. That's why most experienced technicians check and tweak these settings every few weeks. Keeping those clearances spot on means avoiding unnecessary wear and tear on equipment plus saving money on utility bills in the long run.

Effects on Impact Force and Grinding Efficiency

Getting the clearance right makes all the difference in how much force those hammers apply, which ultimately determines just how small the particles get crushed down to. When operators adjust this gap properly, they see better results across the board. Throughput goes up and at the same time, less power gets consumed overall. Some research indicates that getting this setting just right can actually make grinding work 25% more efficiently. So knowing exactly how hammer spacing affects the actual pounding power becomes pretty important if manufacturers want their mills to hit production targets without burning through extra electricity costs every day.

Preventing Premature Wear Through Gap Management

Keeping the right gap between parts matters a lot for stopping unnecessary wear on hammers and screens alike. If those gaps get too tight or too loose, everything starts breaking down faster than it should. Most plant managers know this from experience. When gaps aren't managed properly, replacement costs tend to jump around 30% according to industry reports. That kind of money adds up over time. Spending just a few minutes each day checking those gaps makes all the difference in component longevity. We've seen plants cut their replacement schedule almost in half simply by making small adjustments regularly. Nobody wants to deal with emergency repairs during production hours, so regular maintenance really pays off in the long run.

Rotor Balancing and Vibration Control

Dynamic Balancing Techniques for Rotors

Dynamic balancing makes all the difference when it comes to getting rotor speeds right and cutting down those annoying vibrations in equipment like hammer mills. Properly balanced rotors mean less stress on bearings and other parts, so they last longer before needing replacement. Most manufacturers suggest checking balance regularly according to standard practices in the field. Skipping these routine inspections can lead to rough running machines that eventually break down completely. The money saved from avoiding unexpected repairs often pays for itself many times over, especially considering how expensive downtime becomes when production grinds to a halt because of simple balancing issues.

Vibration Analysis and Mitigation Strategies

Using vibration analysis methods represents a smart way to maintain equipment since problems get spotted long before they turn into big breakdowns. The latest tech for monitoring vibrations really helps keep tabs on those levels and figure out when maintenance might be needed. Some research shows regular checks can cut down maintenance expenses quite a bit sometimes around 20 percent according to what I've seen reported. Companies that adopt this kind of strategy tend to schedule their maintenance work better which means fewer surprise expenses and machines that just plain last longer without giving trouble. Maintenance teams appreciate knowing what's coming next instead of constantly putting out fires.

Extending Bearing and Component Lifespan

Keeping rotor balance and controlling vibrations is essential for making bearings and other parts last longer. Regular maintenance checks help spot problems before they become serious issues that need fixing right away. The numbers support this approach too research indicates bearings can last around 40% longer when properly maintained. For companies running equipment day in and day out, focusing on these maintenance aspects means machines stay operational much longer. This translates to real money saved over time as replacement costs drop significantly and downtime gets minimized across operations.

Wear Parts Monitoring and Management

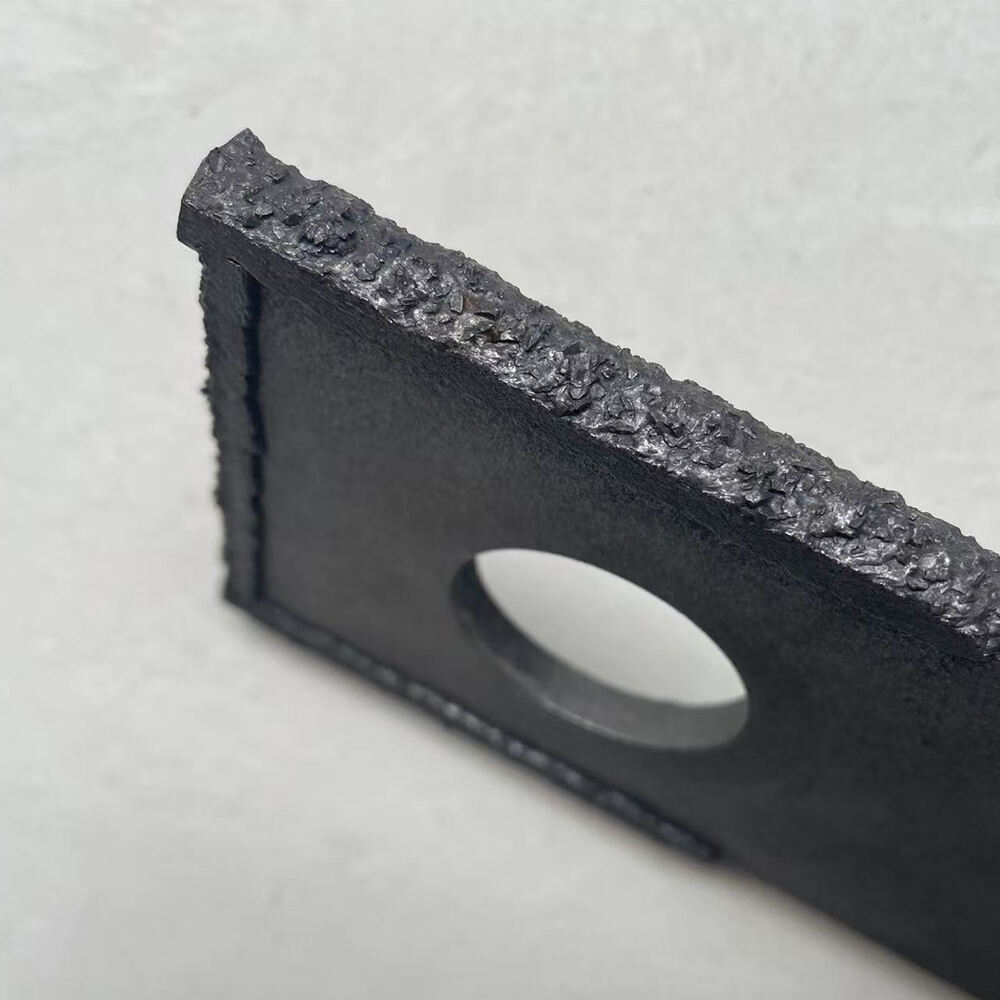

Key Components: Hammers, Beaters, and Liners

Checking hammers, beaters and liners regularly keeps machinery running smoothly, especially in equipment like hammer mills where these parts take a real beating. Knowing how fast they wear down helps plan when replacements are needed before breakdowns happen. Industry folks who've worked with wear parts from companies like Changzhou Hammermill Machinery Technology know that keeping track of component condition pays off big time. Their products stand out because they last longer than standard options and resist wear better too. For factories concerned about downtime and maintenance costs, investing in quality wear components makes sense both economically and operationally over the long haul.

Implementing Preventive Replacement Schedules

Getting organized about when to replace parts before they fail can really cut down on those frustrating unexpected shutdowns. Keeping track of how long different wearing parts last helps plan replacements at just the right time without disrupting operations. The numbers back this up too many plants have found that sticking to a regular replacement schedule keeps production running smoothly day after day. Take tungsten carbide hammer blades for instance these things last way longer than standard options, so companies that switch to them often find themselves replacing components less frequently while still getting great performance from their equipment. This kind of planning saves money in the long run and keeps everyone working toward the same goal of reliable operation.

Reducing Unplanned Downtime Through Proactive Maintenance

When companies implement proactive maintenance plans with regular checks and monitoring, they significantly cut down on those frustrating surprise breakdowns. Predictive maintenance tools let businesses spot potential issues long before anything actually breaks down, giving them time to fix things before production grinds to a halt. Look at the numbers too firms using these methods typically see around a 30% drop in downtime, which speaks volumes about what good maintenance practices can achieve. For manufacturers wanting even better results, partnering with quality suppliers matters a lot. Take Changzhou Hammermill Machinery Technology Co. Ltd. for instance their innovative equipment helps keep operations running smoothly while making it easier to handle those inevitable wear and tear situations that come with any machinery over time.

Advanced Hammer Pattern and Tip Speed Configuration

Customizing Hammer Arrangement for Material Types

Adjusting how hammers are arranged works wonders for grinding efficiency across various materials, especially inside those industrial hammer mills. Each substance has its own quirks, so picking the right hammer setup makes all the difference in breaking down particles effectively. Field tests back this up pretty well, showing around 20% faster grinding when operators take the time to match hammer configurations with what they're actually processing. Getting this right does more than just speed things up though. Proper hammer placement helps maintain that uniform product quality throughout production runs, which matters a lot for manufacturers who need consistency from batch to batch.

Optimizing Tip Speed for Particle Distribution Control

Getting the tip speed right makes all the difference when it comes to managing how particles break down during grinding operations. When operators keep this speed within the correct range, they actually boost how well energy moves through the system, making the whole grinding process work better. Our testing shows that hitting that sweet spot for tip speed gives us much more uniform particle sizes across the board. And let's face it folks, nobody wants inconsistent products coming out of their manufacturing line. That's why most plants spend so much time adjusting these speeds just right before production starts. A little tweak here can save hours of rework later on.

Fine-Tuning for Species-Specific Nutrition Requirements

Adjusting hammer setups for different animal types really makes a difference when it comes to improving what's in their feed. Each kind of feed actually needs certain particle sizes so animals can properly digest and enjoy eating it. Studies have shown time and again that getting these settings right according to what each species actually needs leads to better feed conversion rates, which means healthier animals overall. When farmers match up their hammer mill settings with what nutrition experts recommend, they end up making feed that actually works for pigs, chickens, cattle whatever they're raising. The result? Animals get exactly what they need from their food instead of just going through the motions.

Frequently Asked Questions (FAQs)

What is the role of a hammer mill in grinding operations?

The hammer mill is a crucial component in grinding operations, designed to reduce particle sizes through impact forces, thereby ensuring uniform particle size distribution and enhancing overall product quality.

How can I improve my hammer mill's efficiency?

Efficiency can be improved by maintaining consistent feed rates, selecting proper screen sizes, optimizing hammer and screen clearances, ensuring rotor balance, and regularly inspecting wear parts.

What techniques help in maintaining a steady feed rate in a hammer mill?

Utilizing vibratory feeders or screw conveyors, along with automated monitoring systems, can help maintain a consistent feed rate, ensuring efficient hammer mill operations.

How does tip speed affect the performance of a hammer mill?

The tip speed influences the particle size distribution by controlling the energy transfer necessary for size reduction. Optimizing tip speed can lead to a more homogeneous product output.

Why is managing clearances between hammers and screens important?

Managing these clearances is essential to maximize grinding efficiency and reduce energy consumption. Proper measurement and adjustment prevent excessive wear and energy waste.

Table of Contents

- Maintaining Consistent Feed Rate for Optimal Grinding

- Strategic Screen Size Selection

- Hammer-to-Screen Clearance Optimization

- Rotor Balancing and Vibration Control

- Wear Parts Monitoring and Management

- Advanced Hammer Pattern and Tip Speed Configuration

-

Frequently Asked Questions (FAQs)

- What is the role of a hammer mill in grinding operations?

- How can I improve my hammer mill's efficiency?

- What techniques help in maintaining a steady feed rate in a hammer mill?

- How does tip speed affect the performance of a hammer mill?

- Why is managing clearances between hammers and screens important?