Upprätthåll en konstant påfyllningshastighet för optimal malskapacitet

Vikten av en jämn materialflöde

Att hålla matningsfrekvensen stabil är viktigt när det gäller att få en enhetlig partikelstorlek, något som direkt påverkar produktkvaliteten. Om materialet flödar i samma takt undviker vi de irriterande upp- och nedgångar som stör slipmaskiner som hammelflytor och gör att de antingen arbetar för hårt eller inte tillräckligt. Ingen vill ha sin utrustning att kämpa genom inkonsekventa belastningar. Ett stabilt matningsmedel innebär bättre slipningsresultat över hela linjen. Industriuppgifter visar också ganska imponerande vinster från detta tillvägagångssätt, med vissa anläggningar som rapporterar en förbättring av produktionshastigheten med cirka 20% efter att ha åtgärdat sina flödesproblem. Det finns exempel från verkligheten. För tillverkare som vill effektivisera verksamheten, är det inte bara att undvika fel utan att hålla produktstandarderna höga.

Tekniker för att Stabilisera Ingångsvolymer

Stabiliseringen av insatsvolymerna kräver några smarta metoder. Vibrerande matningsapparater fungerar bra tillsammans med skruvtransportörer för att hålla saker flödar i en stadig takt under hela produktionskör. När tillverkare installerar automatiserade övervakningssystem får de omedelbara data som gör att de kan justera inställningarna efter behov, vilket hjälper allt att fungera smidigare dag efter dag. Ett annat trick är att omforma mathopparna så att materialet inte hoppar sig inuti. Denna enkla förändring säkerställer att inget fastnar och att hela processen fungerar effektivt. Genom att sätta ihop alla dessa metoder får företagen mycket bättre kontroll över sina insatsvolymer, vilket innebär en mer konsekvent produktion från sina produktionslinjer. Automatiserade matningslösningar har blivit ganska vanliga nu, och erbjuder tillförlitliga sätt att balansera insatserna samtidigt som slipningsprocessen blir mycket mer effektiv.

Påverkan på energieffektivitet och produktkvalitet

Att hålla matningsfrekvensen stabil hjälper verkligen till att minska energianvändningen, vilket innebär lägre driftskostnader över tid. När fodret är konsekvent under hela processen tenderar slutprodukten också att vara av bättre kvalitet. Mindre omarbetning och mindre slöseri med material ökar naturligtvis produktiviteten i hela verksamheten. Energimyndigheternas revisioner har visat något intressant - när matningspriserna fluktuerar kan energikostnaderna stiga upp till 15% högre än normalt. Det är en stor hit till bottenlinjen. Å andra sidan, växter som lyckas hålla sina matningsfrekvenser stabila förbränner bara inte så mycket energi. Det finns definitivt ett samband mellan vad som går in stadigt och vad som kommer ut effektivt. För tillverkare som driver slipning, att ta det allvarligt att kontrollera dessa matningsfrekvenser lönar sig på två sätt på en gång. Bättre energibesparingar plus produkter av högre kvalitet? Denna kombination gör skillnaden i att vara lönsam samtidigt som man är miljöansvarig.

Strategisk val av skärmstorlek

Anpassning av skärmöppningar till partikelkrav

Att få rätt skärmstorlek är mycket viktigt om vi vill uppnå rätt partikelstorlekar under slipning, särskilt när vi arbetar med hammare. När nätågorna är rätt uppsatta hjälper de till att sortera material bättre samtidigt som de flesta fina partiklarna hålls intakta, något som verkligen påverkar hur bra slutprodukten ser ut och fungerar. Industrierfarenhet visar att fel skärmstorlekar ofta leder till dålig slipningseffekt, vilket saktar ner produktionslinjerna och skapar alla möjliga problem nedströms. Skärmval handlar inte bara om att göra processer smidigare heller. Det är faktiskt den som avgör om färdiga produkter uppfyller specifikationerna eller inte uppfyller kundernas förväntningar. Många tillverkare har lärt sig detta på det hårda sättet efter att ha hanterat klagomål om oförenlig materialkvalitet som orsakats av felaktiga screeningval.

Justering för material hårdhets egenskaper

Att veta hur hårt materialet faktiskt är spelar en stor roll när man väljer rätt skärmstorlek för bearbetning. När man har att göra med hårdare grejer, behöver folk vanligtvis skärmar med mindre öppningar bara för att få en bra slipning. De flesta tillverkare varnar för att ignorera denna faktor, eftersom deras erfarenhet visar att hårda material slits bort mycket snabbare än mjukare, vilket innebär att man lägger mer pengar på reparationer och nya delar. Att justera skärmstorlekar efter hårdhet är inte bara bra för att säkerställa att utrustningen håller längre. Det påverkar verkligen vad som kommer ut i slutet också. Om skärmarna inte matchas ordentligt blir det inte konsekvent, så operatörer slutar slösa tid och resurser på att försöka lösa problem som kunde ha undvikits från början.

Balans mellan kapacitet och finhet

Att få rätt blandning mellan hur mycket material som bearbetas och hur fin slutprodukten måste vara är fortfarande avgörande för alla som driver slipning. De flesta operatörer finner att det är bättre att ändra skärmstorlek eller lägga till ytterligare skärmsteg samtidigt som produktionsvolymerna är stillräckliga. Vissa branschstudier visar att dessa justeringar kan öka den totala produktiviteten med omkring 15%, även om de faktiska siffrorna varierar beroende på utrustningens kvalitet. Sanningen är att när arbetare tar sig tid att justera skärmstorlekarna ordentligt, gör det en verklig skillnad i vardagen. Mälverk är effektiva och lönsamma eftersom de inte slösar resurser på att jaga perfektion i varje fas av bearbetningen.

Genom att integrera en strategisk val av siktstorlek över dessa parametrar kan effektiviteten och produktiviteten i malloperationerna förbättras, vilket i slutändan stödjer bättre produktkvalitet och processpålitlighet.

Hammar-till-Sikt Avstånds Optimering

Mätning och Justering av Kritiska Avstånd

Det är utrymmet mellan hammarna och skärmarna i en hammarkvarn som gör skillnaden när det gäller hur bra slipningen fungerar. Att få dessa mätningar rätt är mycket viktigt, och det är därför många operatörer tar regelbundet tag i sina klyftor och mätare. När den är ordentligt inställd hjälper den att balansera strömförbrukningen mot de faktiska resultaten från slipprocessen. Från vad vi har sett på fältet, lämnar för mycket utrymme mellan komponenter bara slösar el medan producera underpar output. Det är därför de flesta erfarna tekniker kontrollerar och justerar inställningarna varannan vecka. Att hålla dessa tillstånd på plats innebär att man undviker onödigt slitage på utrustningen och att man i längden sparar pengar på elräkningar.

Effekter på slagkraft och malförmåga

Att få rätt clearance gör skillnad på hur mycket kraft hammarna använder, vilket i slutändan bestämmer hur små partiklarna krossas ner till. När operatörerna justerar detta mellanrum på rätt sätt, ser de bättre resultat över hela linjen. Genomgången ökar och samtidigt förbrukas mindre ström. En del forskning visar att om man gör den här inställningen precis rätt kan sliparararbetet bli 25% effektivare. Så att veta exakt hur hammarspanningen påverkar den faktiska slagkraften blir ganska viktigt om tillverkarna vill att deras fabriker ska nå produktionsmål utan att bränna ut extra elkostnader varje dag.

Förebygg tidig slitage genom att hantera gapet

Att hålla rätt avstånd mellan delarna är mycket viktigt för att förhindra onödigt slitage på både hammare och skärmar. Om de där luckan blir för trånga eller för lösa börjar allt gå sönder snabbare än det borde. De flesta anläggningschefer vet detta från erfarenhet. När luckor inte hanteras på rätt sätt tenderar ersättningskostnaderna att stiga med omkring 30%, enligt branschrapporter. Så mycket pengar samlas över tid. Att spendera bara några minuter varje dag på att kontrollera dessa luckor gör skillnad på komponenternas livslängd. Vi har sett växter skära ner sin ersättningstid nästan med hälften genom att göra små justeringar regelbundet. Ingen vill behöva göra nödreparationer under produktionstid, så regelbundet underhåll lönar sig på sikt.

Rotorbalansering och vibrationskontroll

Dynamiska balanseringsmetoder för rotor

Dynamisk balansering gör skillnaden när det gäller att få rätt rotorsatser och minska de irriterande vibrationerna i utrustning som hammare. Rätt balanserade rotorer innebär mindre belastning av lager och andra delar, så de håller längre innan de behöver bytas ut. De flesta tillverkare föreslår att man kontrollerar balansen regelbundet enligt standardmetoder inom området. Om man hoppar över dessa rutinmässiga kontroller kan det leda till att maskinerna blir grova och så småningom helt sönder. De pengar som sparas genom att undvika oväntade reparationer lönar sig ofta många gånger mer, särskilt när man tänker på hur dyrt nedläggningstider blir när produktionen stannar på grund av enkla balanseringsproblem.

Vibrationsanalys och åtgärdsstrategier

Att använda vibrationsanalysmetoder är ett smart sätt att underhålla utrustning eftersom problem upptäcks långt innan de blir stora fel. Den senaste tekniken för vibrationsövervakning hjälper verkligen att hålla koll på dessa nivåer och räkna ut när underhåll kan behövas. En del forskning visar att regelbundna kontroller kan minska underhållskostnaderna ganska mycket ibland till 20 procent enligt vad jag har sett rapporteras. Företag som använder sig av denna typ av strategi tenderar att planera underhållsarbetet bättre vilket innebär färre oväntade kostnader och maskiner som helt enkelt håller längre utan att ge problem. Underhållsteam uppskattar att veta vad som kommer härnäst istället för att ständigt släcka bränder.

Förbättra livslängd för lager och komponenter

Att hålla rotorbalansen och kontrollera vibrationerna är avgörande för att lager och andra delar ska hålla sig längre. Regelbundna underhållsbesiktningar hjälper till att upptäcka problem innan de blir allvarliga problem som måste åtgärdas omedelbart. Siffrorna stöder detta tillvägagångssätt. Forskning visar att lager kan hålla i sig cirka 40% längre när de underhålls på rätt sätt. För företag som driver utrustning dag efter dag innebär fokus på dessa underhållsaspekter att maskinerna håller sig i drift mycket längre. Detta innebär att det sparas pengar över tid eftersom ersättningskostnaderna sjunker avsevärt och driftstopp minskar.

Övervakning och hantering av slitagekomponenter

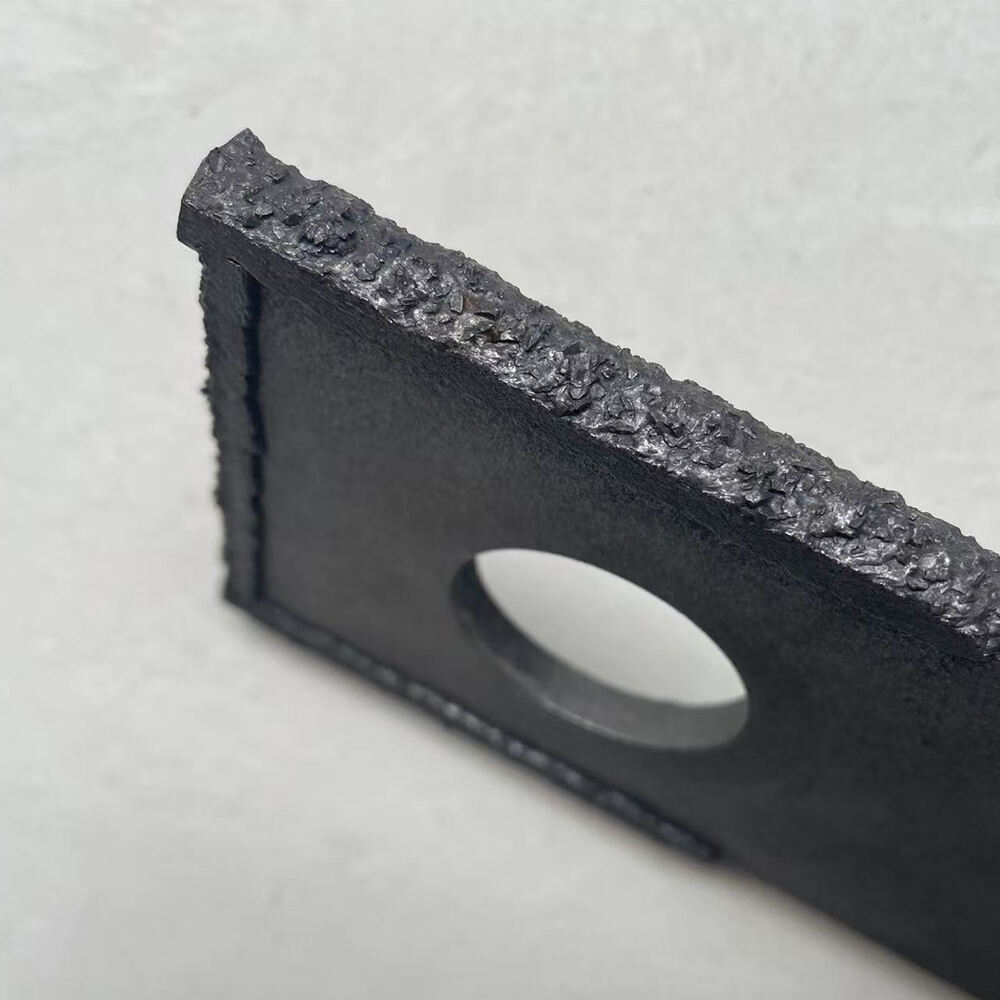

Kritiska komponenter: Hammare, beater och linrar

Att regelbundet kontrollera hammare, slagare och inlägg håller maskinerna i drift, särskilt i maskiner som hammarsmylar där dessa delar får en riktig sla. Att veta hur snabbt de slits bort hjälper dig att planera när det behövs nya innan det händer att de går sönder. Industrifolk som har arbetat med slitage delar från företag som Changzhou Hammermill Machinery Technology vet att hålla reda på komponent tillstånd lönar sig mycket. Deras produkter sticker ut eftersom de håller längre än standardalternativ och också är bättre motståndskraftiga mot slitage. För fabriker som är oroade över driftstopp och underhållskostnader är det både ekonomiskt och operativt meningsfullt att investera i slitagekomponenter av hög kvalitet på lång sikt.

Införande av förebyggande utbytesplaner

Att organisera sig för att ta ut delar innan de går sönder kan verkligen minska de frustrerande oväntade avstängningarna. Att hålla reda på hur länge olika slitna delar håller kan hjälpa till att planera att byta ut dem vid exakt rätt tidpunkt utan att störd drift. För många anläggningar har funnit att det är bra att hålla sig till ett regelbundet ersättningsschema för att produktionen ska gå smidigt dag efter dag. Ta till exempel tungstenkarbidhammersknivar. Dessa saker håller mycket längre än standardalternativ. Så företag som byter till dem ersätter ofta mindre ofta komponenter samtidigt som de får bra prestanda från sina utrustning. Denna typ av planering sparar pengar i det långa loppet och gör att alla arbetar mot samma mål om tillförlitlig drift.

Minska Oplanerat Stopp Genom Proaktiv Underhållsstrategi

När företagen genomför proaktiva underhållsplaner med regelbundna kontroller och övervakning, minskar de dessa frustrerande oväntade avbrott avsevärt. Med hjälp av förutsägbara underhållsverktyg kan företag upptäcka potentiella problem långt innan något faktiskt går sönder, vilket ger dem tid att laga saker innan produktionen stannar. Titta på siffrorna. Företag som använder dessa metoder ser vanligtvis en minskning på 30% av driftstopp, vilket talar för mycket om vad bra underhållspraxis kan uppnå. För tillverkare som vill ha ännu bättre resultat är det viktigt att samarbeta med kvalitetsleverantörer. Ta till exempel Changzhou Hammermill Machinery Technology Co. Ltd. Deras innovativa utrustning hjälper till att hålla verksamheten igång smidigt samtidigt som det blir lättare att hantera de oundvikliga slitage situationer som kommer med alla maskiner över tiden.

Avancerat hammarmönster och tippfartskonfiguration

Anpassning av hammarnas placering efter materialtyp

Att justera hur hamrarna placeras gör underverk för slipningseffektivitet över olika material, särskilt i de industriella hammarbruken. Varje ämne har sina egna kvickheter, så att välja rätt hammarinställning gör skillnaden i att bryta ner partiklar effektivt. Fälttester visar att det går 20% snabbare när operatörerna tar sig tid att matcha hammarkonfigurationerna med det de faktiskt bearbetar. Att göra det här rätt gör mer än att bara påskynda saker. En korrekt placering av hammaren bidrar till att bibehålla den enhetliga produktkvaliteten under hela produktionsperioden, vilket är mycket viktigt för tillverkare som behöver konsistens från batch till batch.

Optimering av spetsfart för kontroll av partikelfördelning

Att få rätt spetshastighet gör skillnad när det gäller att hantera hur partiklar bryts ner under slipning. När operatörerna håller denna hastighet inom rätt intervall ökar de faktiskt hur väl energi rör sig genom systemet, vilket gör hela slipprocessen bättre. Våra tester visar att när vi når den bästa punkten för spetshastighet får vi mycket mer enhetliga partikelstorlekar över hela linjen. Och låt oss inse det folk, ingen vill ha inkonsekventa produkter som kommer ut ur deras tillverkning. Det är därför de flesta anläggningar spenderar så mycket tid att justera dessa hastigheter precis innan produktionen börjar. En liten justering kan spara timmar av omarbetning senare.

Finjustering för artspecifika näringsbehov

Att justera hammarinställningar för olika djurtyper gör verkligen skillnad när det gäller att förbättra vad som finns i deras foder. Varje typ av foder behöver faktiskt vissa partikelstorlekar så att djuren kan smälta och njuta av att äta det. Studier har visat att om man ställer in dessa inställningar rätt, enligt vad varje art faktiskt behöver, så leder det till bättre omvandlingsfrekvenser, vilket innebär hälsosammare djur. När bönder matchar sina hammarebruksinställningar med vad näringsexperter rekommenderar, så får de foder som faktiskt fungerar för grisar, höns, nötkreatur, vad de än höjer. Vad blev resultatet? Djur får precis vad de behöver av maten istället för att bara gå igenom rörelserna.

Frågor som ofta ställs (FAQ)

Vad är rollen för en hammarmal i malningsoperationer?

Hammarmalen är en avgörande komponent i malningsoperationer, utformad för att minska partikelstorlek genom slagkrafter, vilket säkerställer en jämn partikelfördelning och förbättrar den totala produktkvaliteten.

Hur kan jag förbättra min hammarmals effektivitet?

Effektiviteten kan förbättras genom att upprätthålla konstanta matningshastigheter, välja rätt siktstorlekar, optimera hammare och siktavstånd, säkerställa rotorbalans och regelbundna inspektioner av slitagekomponenter.

Vilka tekniker hjälper till att upprätthålla en jämn matningshastighet i en hammarmalta?

Användning av vibratoriska matare eller skruvtransportörer, tillsammans med automatiserade Övervakningssystem, kan hjälpa till att upprätthålla en konstant matningshastighet och säkerställa effektiv drift av hammarmalta.

Hur påverkar spetsens hastighet hammarmaltans prestanda?

Spetshastigheten påverkar partikelstorleksfördelningen genom att styra energioverföringen som krävs för storleksminskning. Optimering av spetshastighet kan leda till en mer homogen produktutgång.

Varför är det viktigt att hantera avstånd mellan hammare och sikt?

Att hantera dessa avstånd är avgörande för att maximera malteffektiviteten och minska energiförbrukningen. Rätt mätning och justering förhindrar onödigt slitage och energislöseri.

Innehållsförteckning

- Upprätthåll en konstant påfyllningshastighet för optimal malskapacitet

- Strategisk val av skärmstorlek

- Hammar-till-Sikt Avstånds Optimering

- Rotorbalansering och vibrationskontroll

- Övervakning och hantering av slitagekomponenter

- Avancerat hammarmönster och tippfartskonfiguration

-

Frågor som ofta ställs (FAQ)

- Vad är rollen för en hammarmal i malningsoperationer?

- Hur kan jag förbättra min hammarmals effektivitet?

- Vilka tekniker hjälper till att upprätthålla en jämn matningshastighet i en hammarmalta?

- Hur påverkar spetsens hastighet hammarmaltans prestanda?

- Varför är det viktigt att hantera avstånd mellan hammare och sikt?