Traditional Hammer Mill Foundations

Gravity-Fed Mechanisms and Basic Functionality

Old school hammer mills have always been popular because they're simple to operate and get the job done efficiently, mainly thanks to how they work with gravity. When materials go into these machines, they just drop down naturally into the milling area without needing complicated feeding systems. Inside, there are basically three main parts working together: swinging hammers that break things apart, screens that control particle size, and the actual grinding chamber where all the action happens. What makes them stand out is that gravity helps everything move along faster through the mill. This means materials keep flowing consistently during processing and spread evenly across the grinding surface. The result? Faster production times and better quality output, which explains why many manufacturers still rely on this basic but reliable technology across different industries today.

Material Limitations and Manual Operation Challenges

Traditional hammer mills are simple enough to operate and pretty efficient most of the time, but they come with their share of headaches too, especially when working with certain types of materials that need extra attention. Take really tough ores or those pesky fibrous stuff for instance they just don't break down easily without putting in serious effort and sometimes special techniques. Mill operators constantly battle with getting the right feed rate going while trying to tweak things based on whatever material comes through the system. This whole process takes constant monitoring and adjustments, which makes hands-on operation absolutely necessary for good results. The problems we've seen with traditional models definitely slow things down in facilities that rely on consistent output volumes and uniform product quality across batches. Looking back over the past decade or so, many manufacturers started developing smarter hammer mill designs precisely because these old school units couldn't keep up with modern industrial requirements anymore.

Industrial Applications of Early Hammer Mills

Back in the day, hammer mills became really important for many different industries, especially food processing and mining operations. Looking at old records from factories shows how these machines boosted output across those sectors, turning tough raw stuff into something actually useful pretty quickly. The way people used hammer mills changed quite a bit over decades too. By the mid 20th century, manufacturers started seeing value in them for completely new purposes like grinding medicinal ingredients or preparing animal feed in agriculture. What makes hammer mills so special is this incredible flexibility they have shown through all sorts of industrial changes. Even though technology keeps advancing, most modern versions still rely on that basic hammer mill concept first developed back when factories needed simple but effective ways to process materials faster than ever before.

Mechanical Evolution of Hammer Mills

Pneumatic Discharge System Innovations

Pneumatic discharge systems in hammer mills mark real progress when it comes to handling materials after milling takes place. What makes these systems stand out is how they cut down on dust getting into the air while things are being produced something that matters a lot for companies working with powders and fine substances. Cleaner work environments result from this kind of innovation, plus workers aren't breathing in so many airborne particles anymore. Take pharmaceutical manufacturing for example where even tiny amounts of contamination can ruin batches worth thousands. Food processors have also adopted these pneumatic setups because they keep products safe and meet those strict hygiene standards without slowing down production speeds much at all.

Variable Speed Drive Implementation

Variable speed drives have really changed how we optimize milling processes for different materials and products. Operators can tweak the hammer mill speeds as needed, which means they get better control over the grinding process when working with all sorts of feedstocks. The flexibility these systems offer actually leads to higher productivity rates and saves quite a bit of energy too. Some studies show mills using variable speed tech typically see output improvements around 20% or more compared to older fixed-speed models. This kind of performance boost makes a big difference in day-to-day operations across many manufacturing facilities.

Rotor Balance Optimization Techniques

Getting the rotor balance right makes all the difference for hammer mill performance and how long these machines last before needing repairs. When running, proper rotor balance cuts down on those annoying vibrations that just eat away at the parts over time. Many facilities now use dynamic balancing methods with laser tech to keep things running smoothly while making adjustments on the fly. The results speak for themselves really. Mills with well balanced rotors process materials faster and need fewer shutdowns for maintenance work. For anyone working with hammer mills day in and day out, spending the time to get this aspect sorted out pays off big time in both productivity and wallet savings.

Safety and Environmental Advancements

Enclosed Housing Designs for Dust Control

The design of enclosed housings for hammer mills has come a long way in recent years when it comes to making workplaces safer and protecting the environment. Most of these improvements aim at cutting down on dust problems that plague many milling operations. These closed systems basically keep dust from getting loose in the air around workers, so people aren't breathing in all those tiny particles that can be bad for their lungs. Some research shows that companies switching to these enclosed setups actually cut dust levels by more than half in many cases. That kind of reduction makes a real difference in keeping the shop floor cleaner and healthier for everyone who works there day after day.

Modern Dust Collection Systems Evolution

Recent improvements in dust collection systems built into hammer mills have boosted efficiency and cut down on running expenses significantly. The latest models trap most of the airborne particles that would otherwise pollute workshop air, which makes a big difference for workers' health and safety. Many manufacturers now use advanced filtration tech like HEPA filters and cyclone separators to stay within EPA guidelines. Some food processing plants report dropping their particulate matter by around 60% after upgrading, which keeps them compliant with OSHA requirements. Plus, these upgraded systems typically consume about 15-20% less electricity than older models, saving money for businesses concerned about both bottom line and environmental footprint.

Meeting Stricter Industrial Safety Standards

Industrial safety regulations keep getting stricter, so manufacturers had to update hammer mills to match these new demands for better protection of workers on site. Today's models come with all sorts of improvements beyond basic compliance, focusing mainly on accident prevention and keeping operators out of harm's way. Most plant managers know from experience that sticking to these safety rules isn't just good practice it saves money too since accidents mean expensive stoppages and potential lawsuits down the road. Things like automatic shut off systems, quick acting emergency stops, and solid protective covers around moving parts help ensure machines run safely day after day, giving everyone confidence that their workplace remains secure.

Digital Transformation in Hammer Mills

Integrated Control Panel Systems

Control panels that integrate all functions are changing how hammer mills work, making things run smoother because operators can watch what's happening right now and make changes as needed. These setups bring together all the controls into one place, which cuts down on confusion when switching between different types of milling tasks. Operators can keep an eye on stuff like motor speed and how much electricity is being used, then tweak settings on the fly to get better results and stop breakdowns before they happen. Some plants that installed these systems saw their production go up by around 15% while using less power overall. For companies still relying on old methods, adopting this tech makes sense for getting more accurate results and cutting down on mistakes made by people who might miss something important during long shifts.

Process Automation Capabilities

Recent improvements in automation technology for hammer mills have cut down on labor expenses quite a bit, plus made operations much more consistent and productive overall. These systems now come with things like automatic feed controls that keep everything running smoothly, making sure all material gets broken down just right as per set parameters. The machines can tweak themselves on the fly too, so there's no need for someone to watch over them constantly throughout the day. Manufacturing plants that switched to this automated approach saw big gains in their output. One factory in particular mentioned seeing nearly half again as much production from the same equipment once they installed these new systems.

Sensor-Based Monitoring Solutions

Putting sensors inside hammer mills makes it possible to predict when maintenance is needed and fine tune operations, which cuts down on unexpected stoppages and keeps things running smoothly. These smart sensors watch over various parts of the machinery all day long, letting staff know about problems way before they actually break something important. Some studies from actual industrial sites show that these tech upgrades cut maintenance bills around 25 percent while keeping machines working longer between repairs. For factories that install this kind of sensor system on their hammer mills, there's a noticeable difference in how reliably everything runs day after day, plus saving money in the long run becomes much easier to achieve.

Energy Efficiency Breakthroughs

Power Consumption Reduction Strategies

Hammer mills have made some pretty impressive strides lately when it comes to cutting down on power usage while still keeping up with performance demands. A lot of manufacturers are now switching to those energy efficient motors that run better and waste less electricity. Some companies have also started playing around with variable load settings, so the mill can adjust how much power it pulls depending on what kind of material goes in and what the end product needs to be. The numbers speak for themselves really. According to an article from Industrial Equipment Journal back in 2022, plants using these new approaches saw their energy bills drop anywhere between 10-15%. That kind of saving adds up fast over time, especially for operations running multiple shifts a day.

Noise Abatement Technologies

Hammer mills generate quite a bit of noise during operation, just like most other industrial equipment out there. To tackle this problem, manufacturers have been working on new materials and designs specifically for cutting down on all that racket. Some companies now use special acoustic insulation materials along with redesigned parts that absorb vibrations better than traditional ones. Plants that switched to these newer models are seeing around 30% less noise overall. Workers appreciate quieter environments obviously, and it also helps them stay within local noise ordinances without hassle. The Environmental Noise Reduction Association actually did some studies showing how well these upgrades work when put into practice at actual facilities across different industries.

Sustainable Material Processing

Making hammer mills work sustainably helps cut down on their environmental footprint significantly. Lately, there's been a lot of attention paid to tracking how much energy gets used during operation and keeping an eye on waste levels too, which has led to better green practices overall. When companies tweak their milling processes just right, they end up producing far less waste while using considerably less power than before. Take one recent paper from the Journal of Cleaner Production for example it showed around a 20 percent boost in sustainability numbers thanks to newer hammer mill models that come with built-in monitoring systems. All this points to why going green matters so much now across industries, especially since hammer mills play such a big part in making those sustainability targets actually achievable in real world manufacturing environments.

Modern Industrial Applications

Agriculture and Biomass Processing

Hammer mills have become pretty important in today's farming operations and biomass processing because they make things run smoother and handle more tasks. These machines basically smash up grains and various farm products into feed that animals can actually eat, which helps farmers manage their herds better and get more out of their land. Looking at real world applications, hammer mills are doing some serious work across the agricultural sector. Take grain processing for instance or turning biomass into usable fuel sources. Research indicates these grinding systems boost output while cutting down on how long it takes to process materials. This matters a lot since farms need to keep up with ever increasing demands from consumers and markets alike.

Pharmaceutical Production Optimization

Getting production right while keeping quality standards high remains a big challenge across the pharmaceutical sector. Hammer mills play a key part here, helping manufacturers break down materials consistently so they can be packaged properly and shipped out efficiently. Take active pharmaceutical ingredients for instance these need to be ground down to very fine particles to work properly when mixed into medications. Companies have actually seen some pretty good results from using hammer mills too. The consistency factor improves dramatically, which means fewer batches get rejected during quality checks. Plus there's less material wasted overall since everything gets processed more evenly. For many drug makers, this equipment isn't just helpful it's become essential for maintaining both regulatory compliance and profit margins in an increasingly competitive market.

Recycling and Waste Management

Hammer mills have made a real difference in how we handle recycling and manage waste across the board. These machines can smash through all sorts of tough materials pretty fast, which means stuff that would otherwise go to landfills gets turned back into something useful again. For companies trying to green up their operations, hammer mills help cut down on waste volumes while actually doing some good for the environment at the same time. Some numbers show these mills can handle tons of material each day, cutting landfill space needed by around 40% in certain facilities. That's not just better for the planet either it saves money too. Most recycling centers report they're able to process materials much faster now that hammer mills are part of their setup, making the whole operation run smoother from start to finish.

Future Trends in Hammer Mill Design

AI Integration for Predictive Maintenance

Bringing AI into hammer mill operations could change how we handle maintenance issues before they actually happen. These smart systems look at all sorts of performance numbers and spot when something might go wrong, so maintenance crews know exactly when to act instead of waiting for breakdowns. Some mills already using AI for this kind of thing report way fewer unexpected shutdowns compared to what they used to experience. The technology isn't perfect yet, but early results show promise. Manufacturers expect that as these AI tools get better over time, hammer mill operators should see even greater improvements in keeping their machines running smoothly without unnecessary interruptions.

Industry 4.0 Connectivity Features

Hammer mill designs are getting a major overhaul thanks to Industry 4.0 technologies that connect machines and integrate data across operations. What we're seeing now is equipment equipped with IoT capabilities allowing plant managers to keep an eye on things from anywhere while running sophisticated analysis on performance numbers. Real time data collection makes all the difference too. Mills can tweak settings on the fly when they spot something off track in the numbers coming in from sensors throughout the facility. Beyond just making day to day operations smoother, this kind of connected system gives companies a real leg up against competitors who still rely on older methods for tracking and fine tuning their production lines.

Material-Specific Engineering Innovations

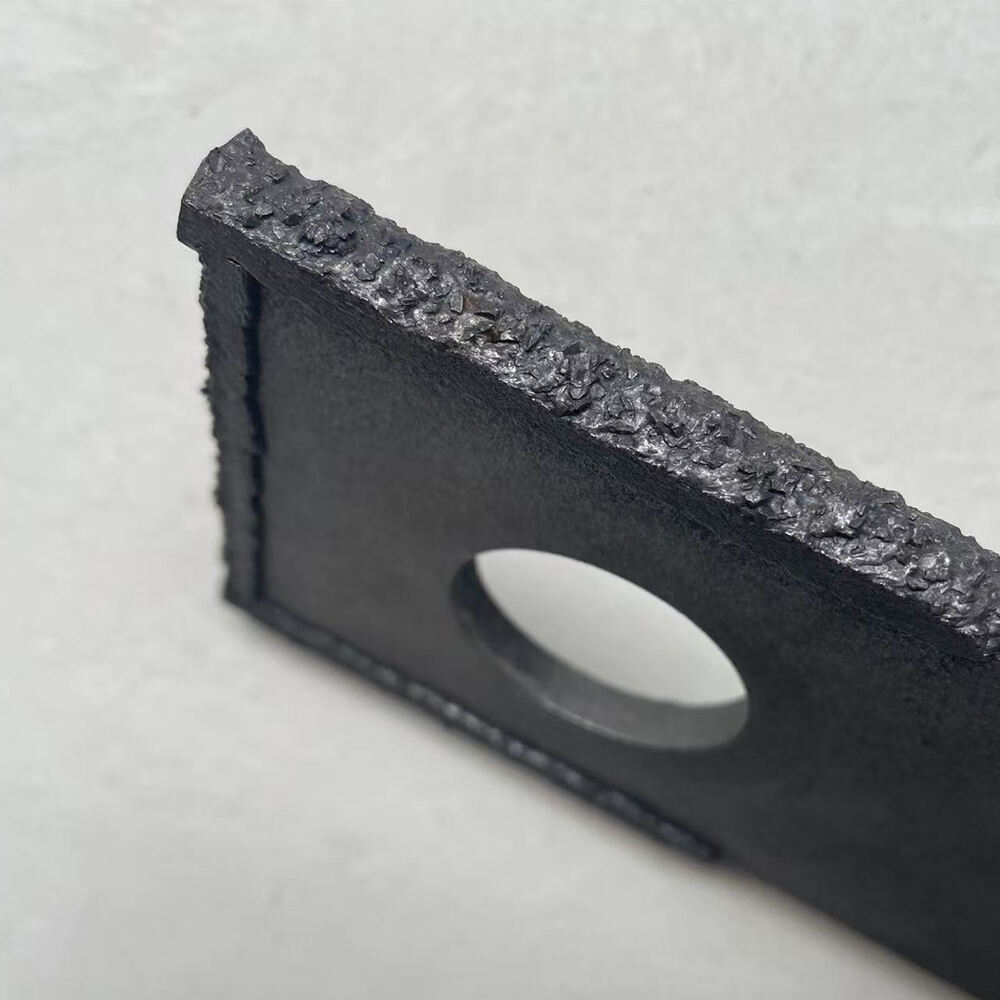

The way hammer mills are being designed nowadays focuses much more on handling particular kinds of materials better than ever before. We've seen some pretty interesting developments lately, especially when it comes to what goes into making those hammer parts and liners last longer while working harder. Take for example the shift toward tougher alloys during manufacturing processes. This change alone has made a real difference when dealing with really hard substances that used to wear down equipment fast. Looking at actual plant operations across different industries shows us something fascinating too. Plants report getting through their material loads faster now, plus their machines aren't breaking down as often because of this focus on matching materials to what they need to process. These improvements speak volumes about why companies keep investing in customized solutions for their hammer mill needs.

FAQ Section

What are traditional hammer mills primarily used for?

Traditional hammer mills are used for milling materials by leveraging a gravity-fed mechanism, which is suitable for transforming raw materials into usable forms efficiently.

What challenges are associated with manual operation of hammer mills?

Manual operation of hammer mills can pose challenges when processing very hard ores or fibrous materials, as it requires more force and specialized handling for optimal performance

How have pneumatic discharge systems improved hammer mills?

Pneumatic discharge systems enhance material handling post-milling by reducing dust exposure and promoting cleaner operations, especially in industries dealing with fine materials.

How do variable speed drives enhance hammer mill operations?

Variable speed drives optimize the milling process by allowing operators to adjust the speed based on materials and product requirements, improving productivity and energy efficiency.

Why is rotor balance important in hammer mills?

Rotor balance is crucial for elevating performance and lifespan, reducing vibrations during operation, which minimizes wear and tear on components.