Bunús na Millí Hama Tréidisiúnta

Cinnteachtaí Graithe agus Oibríocht Bhunúsach

Bhí tóir ar mholláin mhála sean-scoile i gcónaí toisc go bhfuil siad simplí le hoibriú agus an obair a dhéanamh go héifeachtach, go príomha a bhuíochas leis an gcaoi a n-oibríonn siad le tromchúis. Nuair a théann ábhair isteach sna meaisíní seo, titim siad síos go nádúrtha isteach sa limistéar muileála gan gá a bheith acu le córais chomhlánaithe casta. Taobh istigh, tá trí phríomhchuid ann atá ag obair le chéile: marúáin ag snámh a bhriseann rudaí, scáileáin a rialaíonn méid na n-earraí, agus an seomra bruiteála i ndáiríre ina dtarlaíonn an gníomh ar fad. Is é an rud a dhéanann iad a sheasamh amach go bhfuil an tromchúis cabhrú le gach rud a bhogadh ar feadh níos tapúla tríd an muileann. Ciallaíonn sé seo go gcoinníonn ábhair sreabhadh comhsheasmhach le linn próiseála agus go scaiptear iad go cothrom ar fud an dromchla. Cad a tharla? Amanna táirgthe níos gasta agus toradh níos fearr cáilíochta, rud a mhíníonn cén fáth go bhfuil an oiread sin déantúsóirí fós ag brath ar an teicneolaíocht bhunúsach ach iontaofa seo i dtionscail éagsúla inniu.

Teorainneacha Mhaterail agus Dúshlánna Oibríochta Lárnach

Tá muileáin mhála traidisiúnta simplí go leor le feidhmiú agus go leor éifeachtach an chuid is mó den am, ach tagann a gcuid ceannscríofaí leo freisin, go háirithe nuair a bhíonn siad ag obair le cineálacha áirithe ábhar a theastaíonn aird bhreise uathu. Tóg miotail an-deacair nó na rudaí fíosracha annoying mar shampla ní bhíonn siad ach a bhriseadh síos go héasca gan iarracht tromchúiseach a chur agus uaireanta teicnící speisialta. Tá oibreoirí muileann ag troid i gcónaí leis an ráta fóirdheontais cheart a fháil agus iad ag iarraidh rudaí a tweak bunaithe ar aon ábhar a thagann tríd an gcóras. Ní mór an próiseas iomlán seo a mhonatóireacht agus a choigeartú i gcónaí, rud a fhágann go bhfuil oibríocht láimhe riachtanach go hiomlán le haghaidh torthaí maithe. Is cinnte go bhfuil na fadhbanna a chonaic muid le samhlacha traidisiúnta ag moilliú rudaí i saoráidí a bhfuil spleodanna comhsheasmhacha aschuir agus cáilíocht aonfhoirmeach táirgí orthu thar na baisc. Ag breathnú siar thar an deich mbliana anuas nó mar sin, thosaigh go leor déantúsóirí ag forbairt dearaí móra muileann muileann marmóir go beacht toisc nach raibh na heonaid sean-scoile seo in ann leanúint suas le riachtanais thionsclaíocha nua-aimseartha a thuilleadh.

Úsáid Bhainistíochta na Muicileanna Talmha Roimhe Seo

Ar ais sa lá, tháinig muileáin mhála i ndáiríre tábhachtach do go leor tionscail éagsúla, go háirithe próiseáil bia agus oibríochtaí mianadóireachta. Léiríonn féachaint ar sheanchlár ó mhonarcha conas a mhéadaigh na meaisíní an táirgeadh ar fud na hearnálacha sin, ag casadh crua-earraí crua i rud éigin atá úsáideach go maith go tapa. An bealach a úsáideann daoine muileáin mhála athraigh go leor thar na blianta freisin. Faoi lár an 20ú haois, thosaigh monaróirí ag féachaint ar luach iontu chun críocha go hiomlán nua cosúil le comhábhair leighis a mhilleadh nó beatha ainmhithe a ullmhú san talmhaíocht. Is é an rud a dhéanann muileáin mhála chomh speisialta an solúbthacht dochreidte seo a thaispeáin siad trí gach cineál athruithe tionsclaíocha. Cé go leanann an teicneolaíocht ag dul chun cinn, tá an chuid is mó de na leaganacha nua-aimseartha fós ag brath ar an bun-choincheap muileann muileann marmáire a forbraíodh ar dtús ar ais nuair a bhí gá le monarcha bealaí simplí ach éifeachtacha chun ábhair a phróiseáil níos tap

Forbheartú Meaisíníocht Muilinní Hamaid

Nuálaíochtaí i gCórais Scoilte Pneumatacha

Is ionann córais díluchtaithe pneumaiticiúla i mhilíní muilte agus dul chun cinn fíor maidir le hábhair a láimhseáil tar éis an mhilleáin. Is é an rud a dhéanann na córais seo a bheith suntasach ná an chaoi a laghdaíonn siad an deatach a thagann isteach san aer agus rudaí á dtáirgeadh rud a bhfuil an-tábhachtach do chuideachtaí a oibríonn le púdar agus substaintí mionsonraithe. Is mar thoradh ar an cineál nuálaíochta seo a thagann timpeallachtaí oibre níos glaine, chomh maith le go bhfuil oibrithe ag maireachtáil i bhfad níos lú cáithníní san aer. Tóg monarú cógaisíochta mar shampla, áit ar féidir fiú méideanna beaga truaillithe bailiúcháin luach na mílte a scriosadh. Tá na próiseálaithe bia tar éis na socruithe néamáideacha seo a ghlacadh freisin toisc go gcoinníonn siad táirgí sábháilte agus go gcomhlíonann siad na caighdeáin sláintiúla déine sin gan luas táirgeachta a mhoilliú go mór ar chor ar bith.

Cuirfear ar Fhorbairt Athraitheachais Luais

Tá tiománaí luas-athraithe ag athrú i ndáiríre ar an gcaoi a n-optimize muid próisis muileála do ábhair agus táirgí éagsúla. Is féidir le hoibreoirí luasanna na muileann mhála a tweak de réir mar is gá, rud a chiallaíonn go bhfaigheann siad smacht níos fearr ar an bpróiseas meala nuair a bhíonn siad ag obair le gach cineál amhábhar. Is é an solúbthacht a thairgeann na córais seo rátaí táirgiúlachta níos airde agus tá beagán fuinnimh á shábháil acu freisin. Léiríonn roinnt staidéir go bhfeiceann muileáin a úsáideann teicneolaíocht luas athraitheach feabhsuithe toraidh thart ar 20% nó níos mó i gcomparáid le samhlacha níos sine luas seasta. Déanann an cineál seo de ardú feidhmíochta difríocht mhór i n-oibríochtaí laethúla ar fud go leor saoráidí déantúsaíochta.

Téacsanna Cothroime Rotoir

Tá an chothromaíocht ceart rotor ag déanamh an difríochta ar fad maidir le feidhmíocht an mhollán maró agus cé chomh fada agus a mhaireann na meaisíní seo sula dteastaíonn cothabhálacha uathu. Nuair a bhíonn sé ag rith, laghdaíonn cothromaíocht ceart rothar na coimhlintí brónach sin a itheann na páirteanna le himeacht ama. Úsáidtear go leor saoráidí anois modhanna cothromúcháin dinimiciúla le teicneolaíocht léasair chun go leanfaidh rudaí ag rith go réidh agus socruithe á dhéanamh ar an eitilt. Labhraíonn na torthaí dóibh féin i ndáiríre. Déanann muileáin a bhfuil rotars cothrom acu ábhair a phróiseáil níos tapúla agus ní gá go mbeadh níos lú stad orthu le haghaidh obair chothabhála. Maidir le duine ar bith a oibríonn le muileáin mhála lá i agus lá amach, a chaitheamh an t-am chun a fháil ar an ngné seo a shocrú íocann am mór i araon táirgiúlacht agus coigiltis sparán.

Socharra agus Forbairt Chomhshaoil

Dearadhanna Tithe Dúnta chun Rópaí a Rialú

Tá an dearadh árasán clúdaithe do mholláin mhála tar éis dul i bhfad le blianta beaga anuas maidir le suíomhanna oibre a dhéanamh níos sábháilte agus an comhshaol a chosaint. Tá sé mar aidhm ag an chuid is mó de na feabhsuithe seo fadhbanna deataigh a bhíonn ag cur isteach ar go leor oibríochtaí muileála a laghdú. Is iad na córais dhúnte seo a choinníonn deatach ó bheith scaoilte san aer timpeall oibrithe, ionas nach bhfuil daoine ag gabháil isteach na n-earraí beaga sin go léir a d'fhéadfadh a bheith díobhálach dá scamhóga. Taispeánann roinnt taighde go laghdaíonn cuideachtaí a théann chuig na suíomhanna clúdaithe seo leibhéil de chnapáin i ndáiríre níos mó ná leath i go leor cásanna. Is é an cineál sin laghduithe an difríocht i ndáiríre chun an páirc siopadóireachta a choinneáil níos glaine agus níos sláintiúla do gach duine a oibríonn ann lá ar bith.

Éabhlóid na gCóras Bainistíochta Póca

Tá feabhsuithe le déanaí ar chórais bailiúcháin deataigh atá suite i mhilíní muilteora tar éis éifeachtúlacht a mhéadú agus costais oibriúcháin a laghdú go suntasach. Cuimsíonn na samhlacha is déanaí an chuid is mó de na cáithníní atá san aer a dhéanfadh truailliú ar aer na ceardlann ar shlí eile, rud a dhéanann difríocht mhór do shláinte agus sábháilteacht oibrithe. Úsáidtear go leor déantúsóirí teicneolaíocht ardteicneolaíochta scagaithe anois mar scagairí HEPA agus scaradhóirí sioclóin chun fanacht laistigh de threoirlínte EPA. Tuairiscíonn roinnt monarchana próiseála bia go laghdaíonn a gcuid cáithníní suas le thart ar 60% tar éis iad a uasghrádú, rud a choinníonn siad ag teacht le ceanglais OSHA. Ina theannta sin, de ghnáth caitheann na córais uasghrádú seo thart ar 15-20% níos lú leictreachais ná samhlacha níos sine, ag sábháil airgid do ghnólachtaí atá buartha faoi bhunlíne agus faoi chois chomhshaoil araon.

Ag Comhlíonadh Le Rialacha Sábháilteachta Indistriúlaí Neamhuathmhor

Tá rialacha sábháilteachta tionsclaíocha ag éirí níos déine, agus mar sin bhí ar mhonaróirí muileáin mhála a nuashonrú chun freastal ar na héilimh nua seo chun oibrithe ar an láthair a chosaint níos fearr. Tá gach cineál feabhsaithe ag teacht leis na samhlacha atá ann inniu seachas comhlíonadh bunúsach, ag díriú go príomha ar chosc ar thubaistí agus ar oibreoirí a choinneáil ar shiúl ó dhrochdhúile. Tá a fhios ag formhór na mbainisteoirí plandaí ó thaithí nach bhfuil cloí leis na rialacha sábháilteachta seo ach cleachtas maith ach sábhálann sé airgead freisin ós rud é go gciallaíonn timpistí stad costasach agus cásanna féideartha ar an mbóthar. Cabhraíonn rudaí cosúil le córais scoiteamh uathoibríoch, stadanna éigeandála ag gníomhú go tapa, agus clúdach cosaint láidir timpeall páirteanna gluaiseachta le meaisíní a chinntiú go n-oibríonn siad go sábháilte lá ar lá, ag tabhairt muinín do gach duine go bhfanann a n-ionad oibre sábháilte

Athrú Digiteach sa Mhiancair Péinte

Córas Pánaí Isteach Bhunaithe

Tá painéil rialaithe a chomhtháthaíonn na feidhmeanna go léir ag athrú ar an gcaoi a n-oibríonn muileáin mhála, ag déanamh rudaí a reáchtáil níos réidh toisc gur féidir le hoibreoirí féachaint ar a bhfuil ag tarlú anois agus athruithe a dhéanamh de réir mar is gá. Tugann na socruithe seo na rialaithe go léir le chéile in aon áit amháin, rud a laghdaíonn mearbhall nuair a bhíonn tú ag aistriú idir cineálacha éagsúla tascanna muileála. Is féidir le hoibreoirí breathnú ar rudaí cosúil le luas an mhótar agus cé mhéad leictreachais atá á úsáid, ansin a tweak socruithe ar an eitilt chun torthaí níos fearr a fháil agus stopadh briseadh roimh a tharlaíonn siad. Chonaic roinnt plandaí a shuiteáil na córais seo a dtáirgeadh a mhéadú thart ar 15% agus níos lú cumhachta á úsáid acu go ginearálta. I gcás cuideachtaí a bhfuil an-bhraitheach orthu fós ar sheanmhodhanna, is é an teicneolaíocht seo a ghlacadh ciallmhar chun torthaí níos cruinne a fháil agus chun earráidí a dhéanann daoine a d'fhéadfadh rud tábhachtach a chailleann le linn na n-athruithe fada a laghdú.

Cumhachtanna Uathoibriúcháin Próisis

Tá feabhsuithe le déanaí ar theicneolaíocht uathoibrithe do mholláin mhála laghdaithe ar chostais saothair go leor, chomh maith le oibríochtaí a dhéanamh i bhfad níos comhsheasmhaí agus níos táirgiúla go ginearálta. Tá rudaí mar rialaithe fóirdheontaigh uathoibríoch ag teacht leis na córais seo anois a choinníonn gach rud ag rith go réidh, ag cinntiú go ndéantar gach ábhar a bhriseadh síos díreach de réir na paraiméadair socraithe. Is féidir leis na meaisíní iad féin a tweak ar an eitilt freisin, mar sin níl gá le duine éigin a faire orthu go leanúnach i rith an lae. Chonaic monarchana déantúsaíochta a chuaigh ar aghaidh chuig an gcur chuige uathoibrithe seo brabús mór ina dtáirgeadh. Dúirt monarcha amháin go háirithe go raibh beagnach leath níos mó táirgeachta ag an trealamh céanna a athsholáthair nuair a chuir siad na córais nua seo in ionad.

Réitigh Bainneasaíochta Bunaithe ar Shensairí

Is féidir le braiteoirí a chur laistigh de mholláin mhála a thuar nuair is gá cothabháil a dhéanamh agus oibríochtaí a shimpliú, rud a laghdaíonn stad gan choinne agus a choinníonn rudaí ag rith go réidh. Déanann na braiteoirí cliste seo faire ar chodanna éagsúla na meaisín ar feadh an lae, ag ligean do fhoireann a fhios faoi fhadhbanna fada sular bhris siad rud tábhachtach i ndáiríre. Léiríonn roinnt staidéir ó láithreáin thionsclaíocha iarbhír go laghdaíonn na nuashonruithe teicneolaíochta seo billí cothabhála thart ar 25 faoin gcéad agus go gcoinníonn siad meaisíní ag obair níos faide idir deisiúcháin. I gcás mhonarcha a shuiteálann an cineál seo córais braiteora ar a gcuid muileáin mhála, tá difríocht suntasach ann i gcaoi a n-oibríonn gach rud go hiontaofa lá ar lá, chomh maith le airgead a shábháil sa fhadtéarma a bheith i bhfad níos éasca a bhaint amach.

Briseáin Idirbhliantachach Énergéige

Straitéisí Láimhsealaí Cúiseanna Fuinnimh

Tá dul chun cinn iontach déanta ag muileáin mhála le déanaí maidir le tomhaltas fuinnimh a laghdú agus riachtanais feidhmíochta a choinneáil fós. Tá go leor monaróirí ag aistriú anois chuig na mótar atá éifeachtúil ó thaobh fuinnimh de a fheidhmíonn níos fearr agus a chailleann níos lú leictreachais. Thosaigh roinnt cuideachtaí ag imirt le socruithe ualach athraitheacha freisin, ionas gur féidir leis an mhilinne an méid cumhachta a tharraingíonn sé a choigeartú ag brath ar an gcineál ábhair a théann isteach agus cad is gá don táirge deiridh a bheith ann. Labhraíonn na huimhreacha dóibh féin i ndáiríre. De réir alt ó Industrial Equipment Journal ar ais i 2022, chonaic plandaí a úsáideann na modhanna nua seo a mbille fuinnimh ag titim idir 10-15%. Tá an cineál sin coigiltis ag cur suas go tapa le himeacht ama, go háirithe le haghaidh oibríochtaí ag rith il-sciath sa lá.

Teicneolaíochtaí Laghdaithe Fuaim

Tá an-chuid torann ag muileáin mhála le linn oibriú, díreach cosúil le formhór na n-uirlisí tionsclaíocha eile amuigh ansin. Chun dul i ngleic leis an bhfadhb seo, tá monaróirí ag obair ar ábhair agus ar dhearadh nua go sonrach chun an raca sin go léir a laghdú. Úsáidann roinnt cuideachtaí ábhair speisialta inslithe fuaime anois mar aon le páirteanna athdheartha a ghlacann coimhlintí níos fearr ná na páirteanna traidisiúnta. Tá na plandaí a chuaigh ar aghaidh chuig na samhlacha nua seo ag féachaint ar thart ar 30% níos lú torann i gcoitinne. Is léir go bhfuil meas ag oibrithe ar thimpeallachtaí níos ciúine, agus cabhraíonn sé leo fanacht laistigh de na forordaíochtaí torracha áitiúla gan trioblóid. Rinne an Cumann um Laghdú Torann Comhshaoil roinnt staidéir a léiríonn cé chomh maith agus a oibríonn na feabhsuithe seo nuair a chuirtear i bhfeidhm iad i bhfíricí fíor-stáblaí ar fud tionscal éagsúla.

Próiseáil Ghnóthach Comhshaoil

Cuidíonn obair inbhuanaithe muileáin mhála a dhéanamh le laghdú suntasach a dhéanamh ar a gcloigeann chomhshaoil. Le déanaí, tá go leor aird curtha ar an méid fuinnimh a úsáidtear le linn oibriúcháin a rianú agus aird a choinneáil ar leibhéil dramhaíola freisin, rud a d'fhág go raibh cleachtais ghlan níos fearr ann go ginearálta. Nuair a dhéanann cuideachtaí a bpróisis muileála a threisiú go díreach, bíonn siad ag táirgeadh i bhfad níos lú dramhaíola agus ag úsáid níos lú cumhachta ná mar a bhí roimhe seo. Tóg páipéar le déanaí ó Iris na Táirgthe Níos Glan mar shampla léirigh sé méadú thart ar 20% i líon na inbhuanaitheachta a bhuíochas le samhlacha nua-aimseartha muileann marmár a thagann le córais faireála tógtha isteach. Tugann sé seo le fios cén fáth go bhfuil an oiread sin tábhachta ag dul in uachtar reoite anois i ngach tionscal, go háirithe ós rud é go bhfuil ról mór ag muileáin mhála chun na spriocanna inbhuanaitheachta sin a dhéanamh in ann iad a bhaint amach i dtimpeallachtaí déantúsaíochta fíor-aimsire.

Feidhmeannaíocht Tionsclaíochtúil Nua-aimseartha

Talmhaíocht agus Próiseáil Bhitheolais

Tá muileáin mhálaithe ina n-ábhar tábhachtach i n-oibríochtaí feirmeoireachta agus próiseála bithmhaise an lae inniu toisc go ndéanann siad rudaí a reáchtáil níos réidh agus go ndéanann siad níos mó tascanna a láimhseáil. Go bunúsach, déanann na meaisíní seo gráin agus táirgí feirme éagsúla a bhriseadh síos ina bhia is féidir le hainmhithe a ithe i ndáiríre, rud a chabhraíonn le feirmeoirí a gcuid eallaigh a bhainistiú níos fearr agus níos mó a fháil as a gcuid talún. Ag féachaint ar na hiarratais fíor-saoghail, tá muileáin mhála ag déanamh roinnt oibre tromchúiseach ar fud na hearnála talmhaíochta. Tóg próiseáil gráin mar shampla nó bithmhaise a thiontú ina fhoinsí breosla inúsáidte. Léiríonn taighde go gcuireann na córais meala seo méadú ar an toradh agus go laghdaíonn siad an t-am a thógann sé ábhair a phróiseáil. Tá sé seo an-tábhachtach ós rud é go gcaithfidh feirmeoirí freastal ar éilimh atá ag méadú i gcónaí ó thomhaltóirí agus ó mhargaí araon.

Optamúint ar Tháirgeadh Fhármaceutach

Tá sé fós dúshlánach táirgeadh ceart a fháil agus caighdeáin ard cháilíochta á gcoimeád i ngach earnáil cógaisíochta. Tá ról lárnach ag muileáin mhála anseo, ag cabhrú le monaróirí ábhair a bhriseadh síos go comhsheasmhach ionas gur féidir iad a phacáil i gceart agus a sheoladh amach go héifeachtach. Tóg comhábhair ghníomhacha cógaisíochta mar shampla ní mór iad seo a phéinteáil síos go cáithníní an-bhog chun oibriú i gceart nuair a mheascadh i ndrugaí. Tá torthaí maith ag cuideachtaí freisin ó mholláin mhála a úsáid. Feabhsaíonn an fachtóir comhsheasmhachta go suntasach, rud a chiallaíonn go ndiúltófar níos lú bailiúchán le linn seiceálacha cáilíochta. Chomh maith leis sin tá níos lú ábhar a dramhaíl i gcoitinne ós rud é go bhfuil gach rud a phróiseáil níos cothrom. I gcás go leor déantúsóirí drugaí, ní hamháin go bhfuil an trealamh seo cabhrach, ach tá sé riachtanach chun comhlíonadh rialacháin agus brabúis a choinneáil i margadh atá ag éirí níos iomaíoch.

Athchúrsáil agus Bainistíocht dramhaíola

Tá na muileáin mhála tar éis difríocht mhór a dhéanamh ar an gcaoi a láimhseálann muid athchúrsáil agus dramhaíl a bhainistiú ar fud an bhoird. Is féidir leis na meaisíní seo gach cineál ábhar crua a bhriseadh go tapa, rud a chiallaíonn go mbraitheann rudaí a rachadh go dtí dramhaíl ina n-úsáidte arís. I gcás cuideachtaí atá ag iarraidh a gcuid oibríochtaí a dhéanamh níos glas, cuireann muileáin mhála cuidiú le méid na dramhaíola a laghdú agus go ndéanann siad rud maith don chomhshaol ag an am céanna. Léiríonn roinnt uimhreacha gur féidir leis na muileáin seo tonna ábhar a láimhseáil gach lá, ag laghdú spás dramhaíola a theastaíonn thart ar 40% i saoráidí áirithe. Ní hamháin go bhfuil sé sin níos fearr don phláinéid, ach sábhálann sé airgead freisin. Tuairiscíonn an chuid is mó de na hionaid athchúrsála go bhfuil siad in ann ábhair a phróiseáil i bhfad níos tapúla anois go bhfuil muileáin mhála mar chuid dá socraíocht, rud a fhágann go ritheann an oibríocht iomlán níos réidh ón tús go dtí an deireadh.

Treandanna Amach anseo i ndearadh Buailéirí

Comhtháthú AI le haghaidh Coiscréidimh Réamhinspéachtaí

D'fhéadfadh AI a thabhairt isteach i n-oibríochtaí muileann muileann athrú ar an gcaoi a láimhseálann muid fadhbanna cothabhála sula dtarlaíonn siad i ndáiríre. Féachann na córais cliste seo ar gach cineál uimhreacha feidhmíochta agus cuireann siad in iúl nuair a d'fhéadfadh rud éigin dul mícheart, ionas go mbeidh a fhios ag foirne cothabhála go díreach cathain a ngníomhú seachas fanacht le briseadh. Tuairiscíonn roinnt muilteáin atá ag úsáid AI cheana féin le haghaidh rudaí den sórt sin go bhfuil níos lú dúnadh gan choinne i gcomparáid leis an méid a bhí acu. Níl an teicneolaíocht foirfe fós, ach tá torthaí tosaigh geallta. Táthar ag súil go bhfeicfidh oibreoirí muileann marmár feabhsaithe níos mó agus na huirlisí AI seo ag feabhas a chur le himeacht ama agus go mbeidh feabhas níos mó acu ar a gcuid meaisíní a choinneáil ag rith go réidh gan scoilteanna neamhriachtanacha.

Gnéithe Ceangail Industry 4.0

Tá dearadh na muileann maró ag fáil athchóiriú mór a bhuíochas do theicneolaíochtaí Tionscail 4.0 a nascann meaisíní agus a chomhtháthraíonn sonraí ar fud oibríochtaí. Is é an rud atá le feiceáil againn anois ná trealamh atá feidhmiúil le cumas IoT a ligeann d'fheidhmeannaithe plandaí súil a choinneáil ar rudaí ó áit ar bith agus anailís chasta á reáchtáil ar líon feidhmíochta. Déanann bailiú sonraí i bhfíor-am an difríocht freisin. Is féidir le muilteáin a tweak socruithe ar an eitilt nuair a shocraíonn siad rud éigin as an rian i na huimhreacha a thagann isteach ó braiteoirí ar fud an saoráide. Ní hamháin go ndéanann an córas nasctha seo oibríochtaí laethúla níos suaimhneacha, ach tugann sé buntáiste fíor do chuideachtaí i gcoinne iomaitheoirí a bhfuil brath acu fós ar sheanmhodhanna chun a línte táirgthe a rianú agus a shimplíniú.

Nuashonruithe Innealtóireachta Sonracha do Mhacasamhail

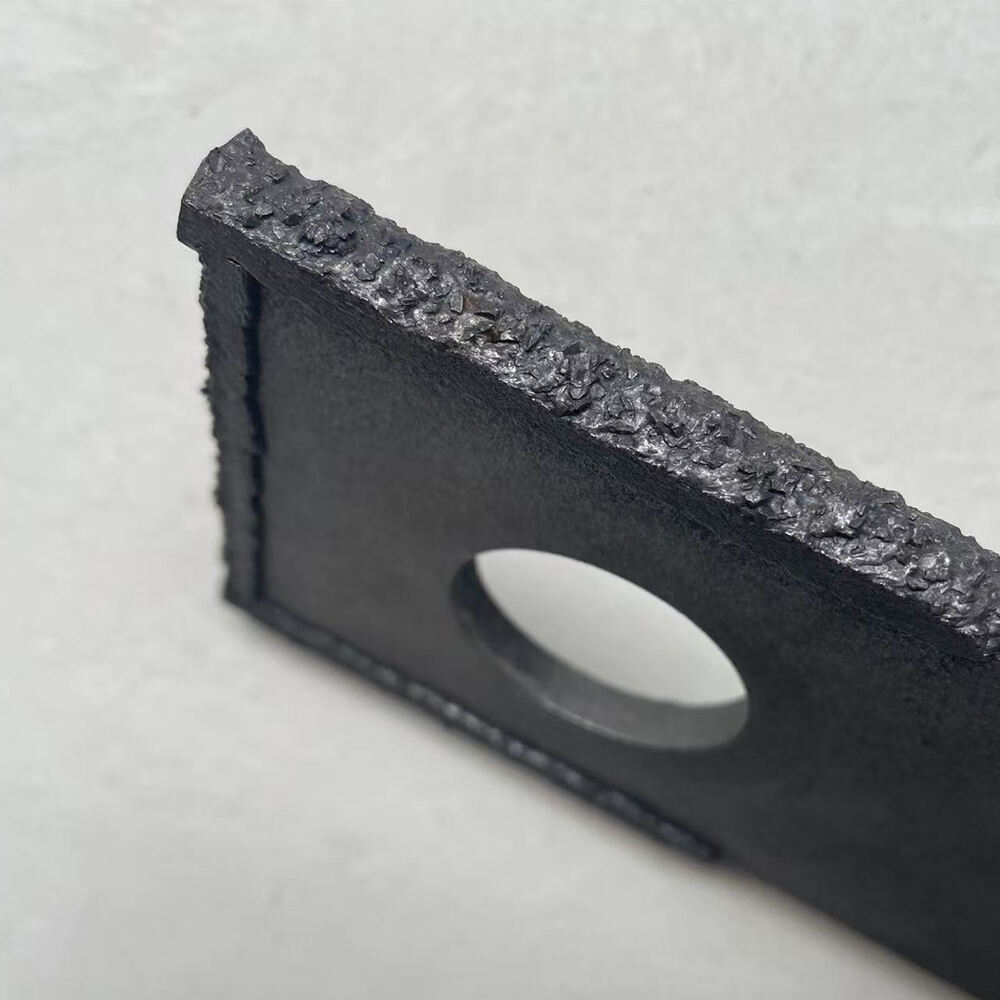

Tá an bealach a ndéantar muileáin mhála a dhearadh inniu dírithe i bhfad níos mó ar cineálacha áirithe ábhar a láimhseáil níos fearr ná riamh. Chonaic muid roinnt forbairtí suimiúla le déanaí, go háirithe nuair a thagann sé chun na rudaí a théann isteach chun na páirteanna agus na liners marm a dhéanamh a mhaireann níos faide agus iad ag obair níos deacra. Tóg an t-athrú chun cóimhiotail níos crua le linn phróisis déantúsaíochta mar shampla. Tá an t-athrú seo amháin tar éis difríocht fíor a dhéanamh nuair a bhíonn sé i gceist le substaintí an-deacair a úsáideadh chun trealamh a chaitheamh go tapa. Léiríonn breathnú ar oibríochtaí iarbhír na mbonneachta ar fud tionscal éagsúla rud éigin iontach dúinn freisin. Tuairiscíonn na plandaí go bhfuil siad ag dul trína n-ualach ábhair níos tapúla anois, chomh maith le go bhfuil a gcuid meaisíní ag briseadh síos níos minice mar gheall ar an bhócas seo ar ábhair a chur i gcomhar leis an méid a theastaíonn uathu a phróiseáil. Labhraíonn na feabhsuithe seo go leor faoi cén fáth go bhfuil cuideachtaí ag leanúint ag infheistiú i réitigh saincheaptha dá riachtanais muileann an mhála.

Rannán Ceisteanna Coitianta

Cá bhfuil comhphoblachtaí péinteála traidisiúnta á úsáid don?

Úsáidtear comhphoblachtaí péinteála traidisiúnta don gcruthú a bheith déanta ar mheáin trí úsáid a bheith déanta de mheánacht an domhain, a chuireann isteach ar mhéadú ar an gcruthú go héifeachtach.

Cá na triailbheanna a bhaineann le hoibríocht láimhe na gcomhphoball péinteála?

Is féidir oibríocht láimhe na gcláiríní beag a chuir fadhbanna ar aghaidh nuair a bheidh i bhfóintreacht an-tiom fluich nó tairsis, mar is gá le níos mó fórsa agus lámhseáil speisialta chun feidhmíocht choibhéadach a bhaint amach

Conas a hilligh siostéam píobála díosgailte cláiríní beag?

Is é atá ag siostéam píobála díosgailte ná go hionann leithidh an t-ádhais tar éis milleadh trí laghdú a dhéanamh ar an ndust agus tríd is féidir oibríocht ghlanaithe a chur chun cinn, go háirithe i meitheal a bheidh ag dealú le hairneachtaí caol.

Conas a thugann tiománaí luathais athraithe feabhas ar oibríocht na gcláiríní beag?

Oibríonn tiománaí luathais athraithe ar an bprowinséad milleadh trí ligean do na hoibrithe luaths a riar bunaithe ar na hairneachtaí agus ar riachtanais na dtorthaí, ag cur suas ar tháirgiúlacht agus éifeachtúlacht fuinnimh.

Cén fáth a tá cothromú rota important in hammer mills?

Tá cothromú rotaí ríthábhachtach chun feidhmíocht agus saol a ardú, ag laghdú ar chruaidheacht san oibríocht, rud a laghdaíonn úsáid agus caillteanas ar chuidí.

Clár na nÁbhar

- Bunús na Millí Hama Tréidisiúnta

- Forbheartú Meaisíníocht Muilinní Hamaid

- Socharra agus Forbairt Chomhshaoil

- Athrú Digiteach sa Mhiancair Péinte

- Briseáin Idirbhliantachach Énergéige

- Feidhmeannaíocht Tionsclaíochtúil Nua-aimseartha

- Treandanna Amach anseo i ndearadh Buailéirí

-

Rannán Ceisteanna Coitianta

- Cá bhfuil comhphoblachtaí péinteála traidisiúnta á úsáid don?

- Cá na triailbheanna a bhaineann le hoibríocht láimhe na gcomhphoball péinteála?

- Conas a hilligh siostéam píobála díosgailte cláiríní beag?

- Conas a thugann tiománaí luathais athraithe feabhas ar oibríocht na gcláiríní beag?

- Cén fáth a tá cothromú rota important in hammer mills?