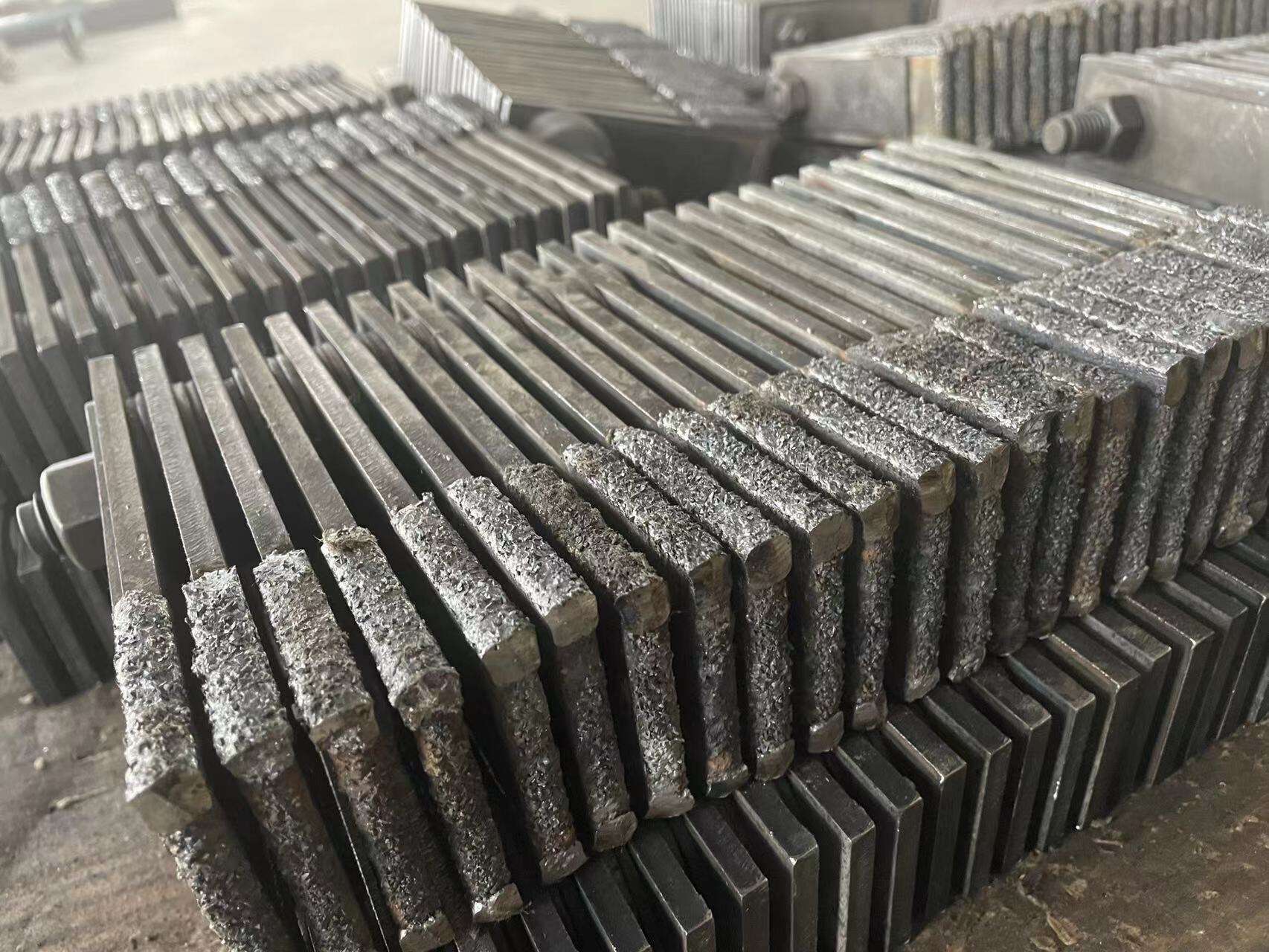

die for pellet mill

A die for pellet mill is a crucial component in the pelletizing process, serving as the primary forming tool that determines the quality and consistency of the final pellet products. This precision-engineered component features a cylindrical shape with multiple carefully designed holes through which the raw material is extruded. The die's surface is manufactured using high-grade stainless steel or alloy steel, ensuring durability and resistance to wear under high pressure and temperature conditions. The diameter and length of the die holes, known as the compression ratio, are specifically calculated to match different raw materials and desired pellet specifications. Modern pellet mill dies incorporate advanced hole patterns and surface treatments that optimize material flow and reduce energy consumption during the pelletizing process. The die works in conjunction with rollers that press and force the material through the holes, creating uniformly sized pellets. These dies are available in various specifications, including different hole sizes, compression ratios, and material compositions, making them suitable for processing diverse materials such as biomass, animal feed, and wood products. The effective lifespan of a pellet mill die depends on factors such as maintenance practices, material properties, and operating conditions.