flat die wood pellet mill

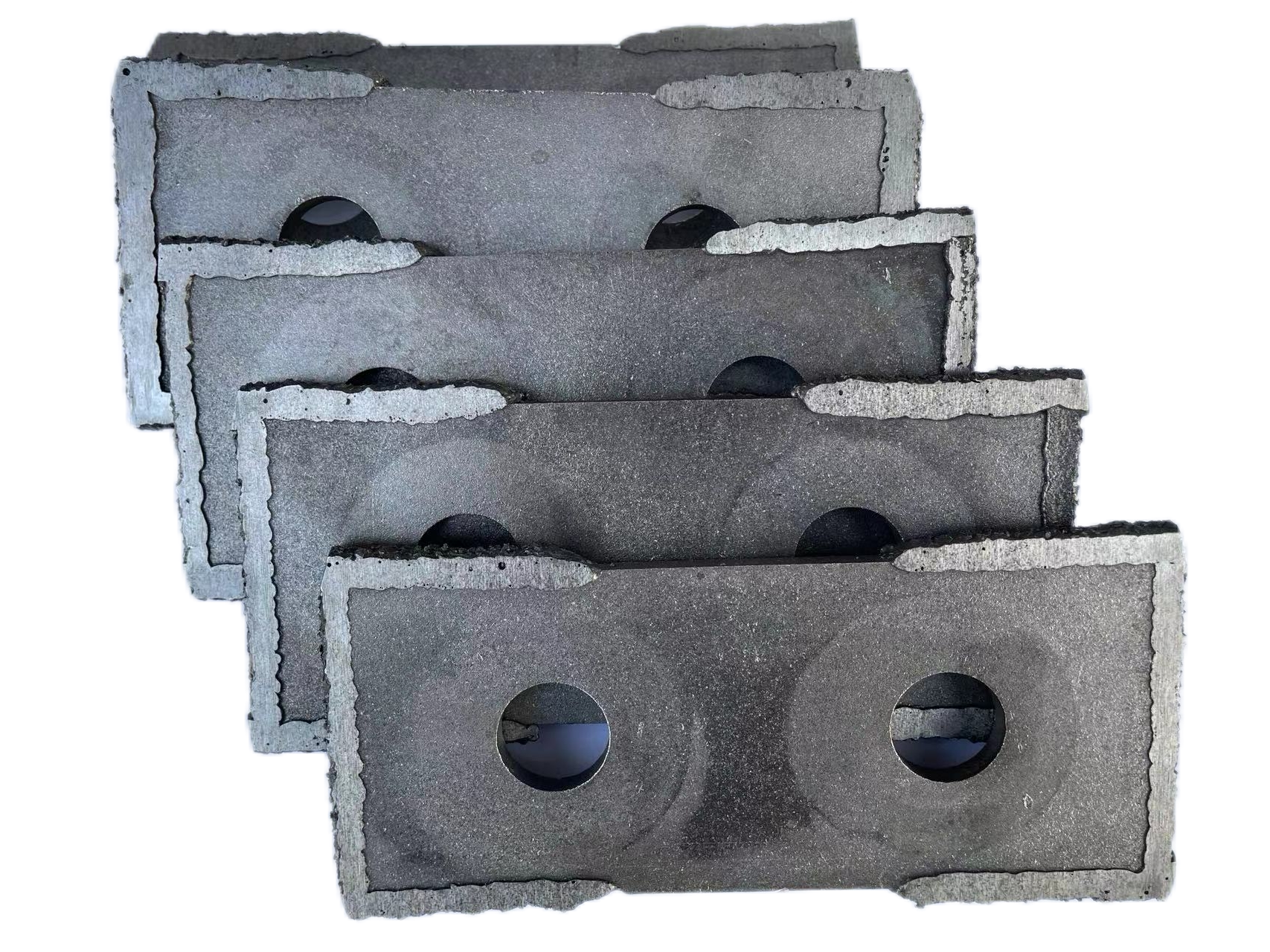

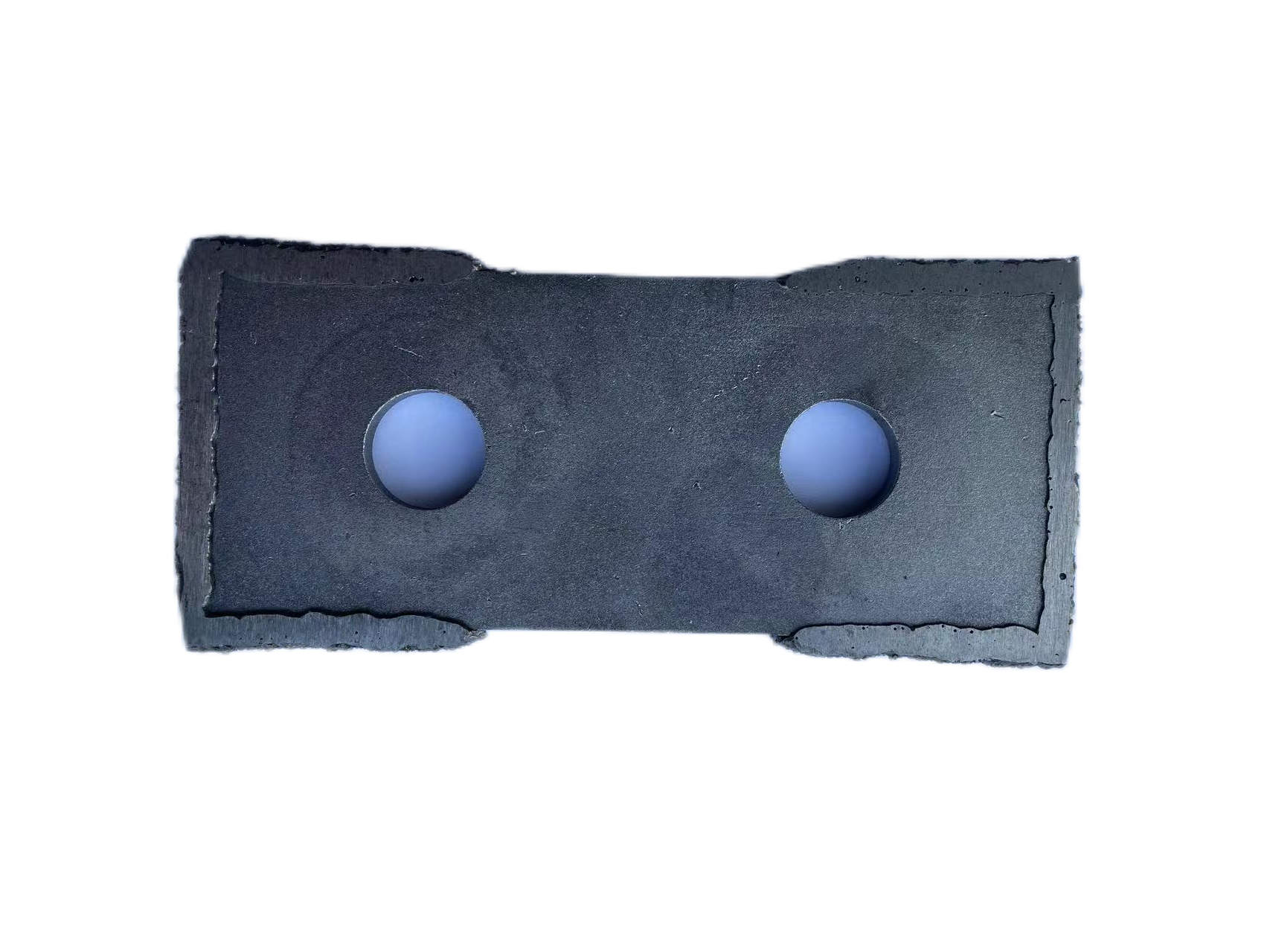

The flat die wood pellet mill represents a cutting-edge solution in biomass processing technology, designed to efficiently convert raw wood materials into high-quality, densified pellets. This sophisticated machinery operates through a straightforward yet effective process where wood material is compressed through a flat die plate containing multiple holes. The compression is achieved through rotating rollers that force the material through these precisely engineered holes, creating uniform, cylindrical pellets. The mill's design incorporates advanced features such as automatic feeding systems, precise temperature control mechanisms, and adjustable roller pressure settings, ensuring consistent pellet quality and production efficiency. The system's versatility allows it to process various types of wood materials, including sawdust, wood chips, and agricultural residues, making it suitable for multiple industrial applications. The mill's robust construction ensures durability and reliable operation under continuous production conditions, while its modular design facilitates easy maintenance and parts replacement. This equipment has become essential in industries ranging from biofuel production to animal feed manufacturing, offering a sustainable solution for biomass processing needs.