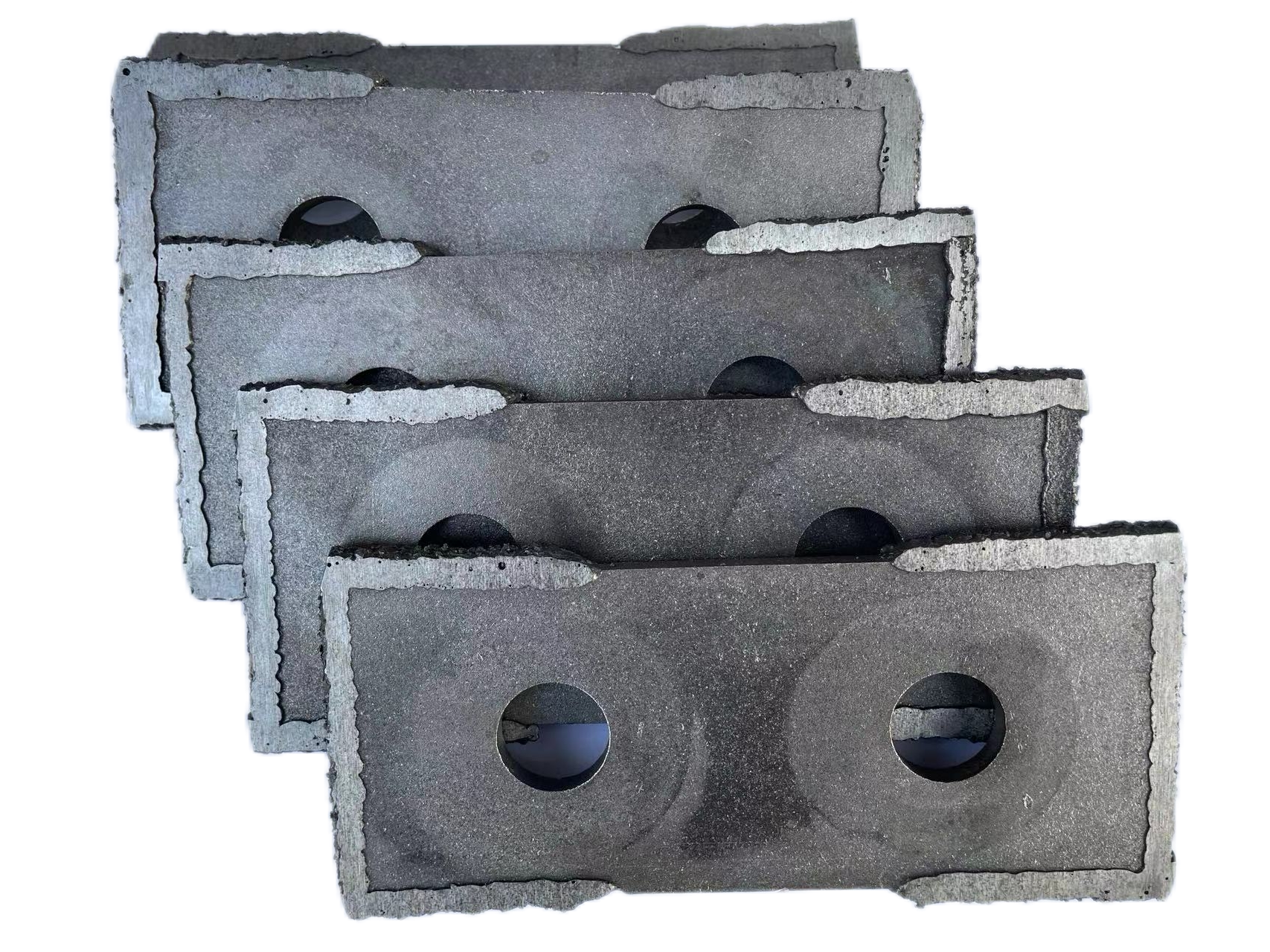

pellet mill die

A pellet mill die is a crucial component in pellet production machinery, serving as the primary element responsible for transforming raw materials into uniform, densified pellets. This precision-engineered tool consists of a hardened steel ring with multiple precisely drilled holes, through which material is forced to create pellets of consistent size and density. The die's design incorporates specific compression ratios and hole patterns optimized for different materials, ensuring efficient pellet formation while maintaining structural integrity. Modern pellet mill dies feature advanced metallurgical compositions that provide extended wear resistance and optimal performance under high-pressure conditions. The working surface of the die includes carefully calculated hole patterns that facilitate proper material flow and compression, while the thickness and hole diameter ratio is precisely engineered to achieve the desired pellet quality. These dies are essential in various industries, including animal feed production, biomass fuel manufacturing, and organic waste processing, where they enable the efficient conversion of raw materials into manageable, uniform pellets.