mini pellet machine

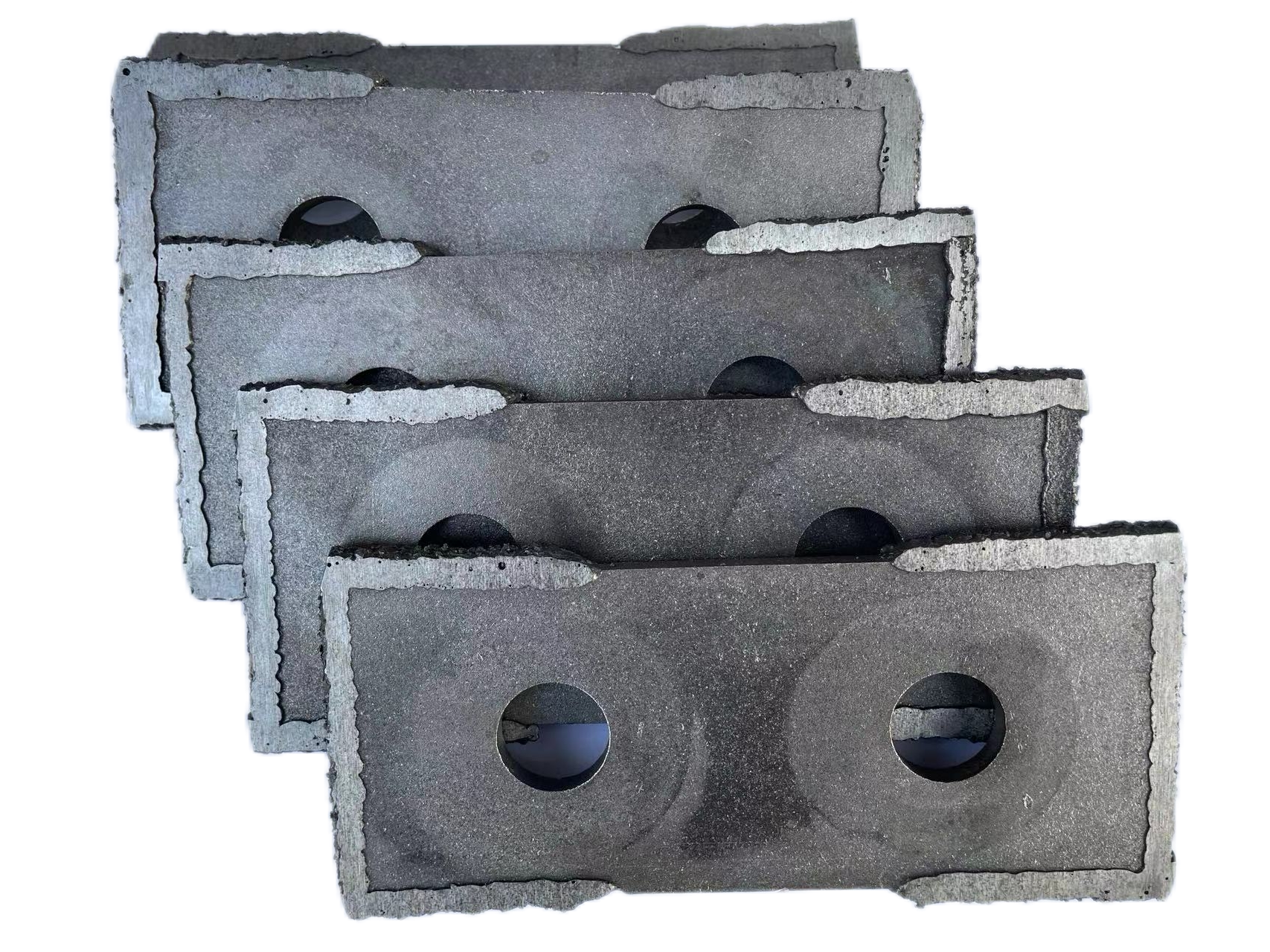

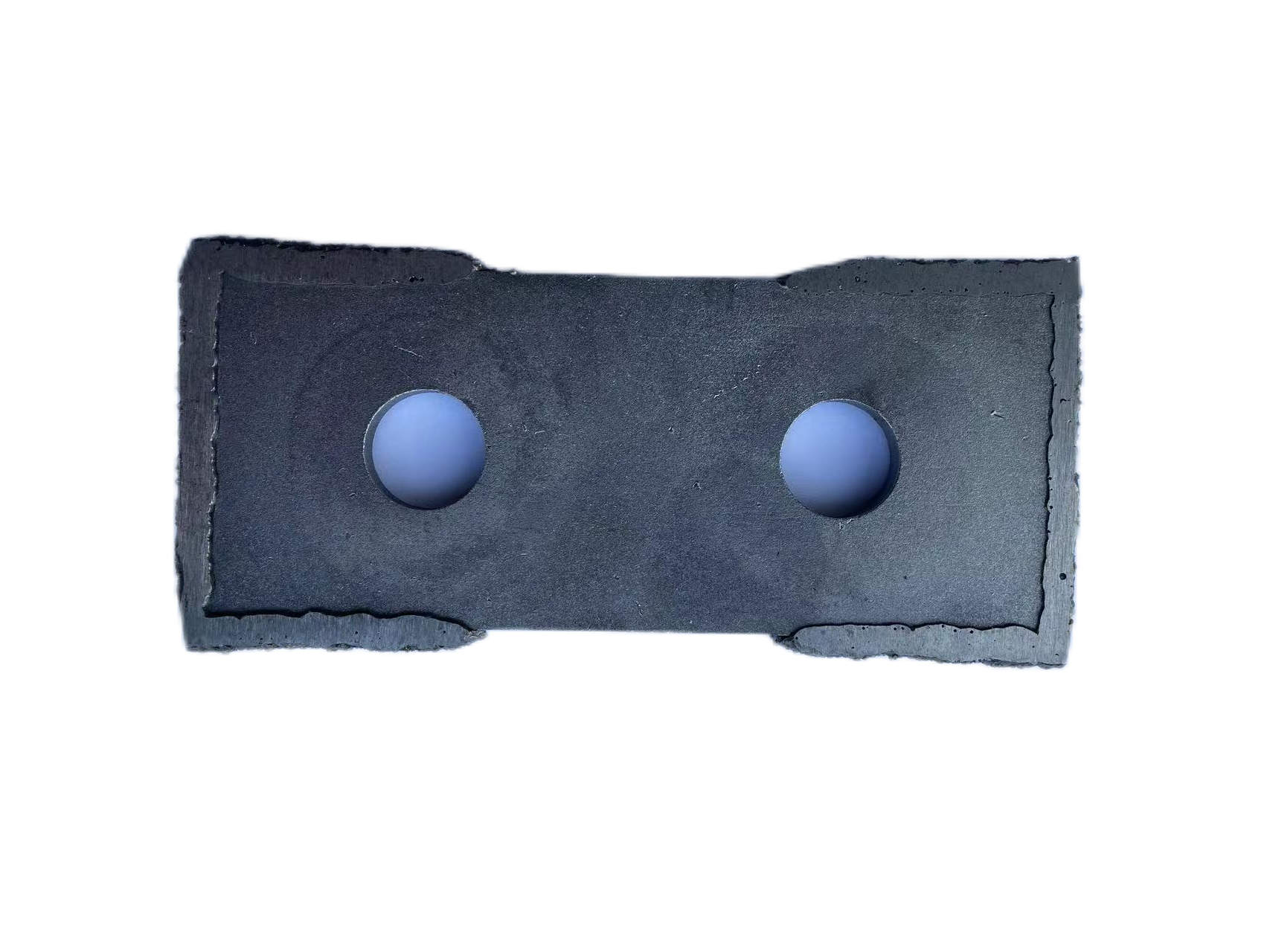

The mini pellet machine represents a revolutionary advancement in small-scale pellet production technology. This compact yet powerful equipment efficiently transforms various raw materials including biomass, feed, and wood materials into high-quality pellets. The machine features a robust design with a precision-engineered die and roller system that ensures consistent pellet formation. Operating at optimized temperatures and pressures, it can process 50-100 kg of material per hour, making it ideal for small businesses and personal use. The machine incorporates an intelligent control system that monitors and adjusts processing parameters in real-time, ensuring product quality and operational efficiency. Its versatility allows for processing multiple raw materials, from agricultural residues to wood sawdust, with minimal adjustments required between different materials. The unit comes equipped with advanced safety features including automatic shutdown protection and overload prevention systems. Additionally, its energy-efficient design helps minimize operational costs while maintaining high production standards.