Optimizing Industrial Grinding Performance Through Proper Blade Care

The efficiency and longevity of hammer mill operations heavily depend on the condition of their cutting components. Hammer mill blades serve as the cornerstone of size reduction processes across various industries, from agriculture to recycling. Understanding proper maintenance techniques not only extends the life of these crucial components but also ensures consistent product quality and reduces operational costs.

Professional maintenance of hammer mill blades involves a systematic approach that combines regular inspection, timely replacement, and proper handling procedures. When implemented correctly, these practices can significantly improve operational efficiency and minimize unexpected downtime.

Essential Components of Blade Maintenance Strategy

Regular Inspection Protocols

Implementing a robust inspection schedule is crucial for maintaining optimal hammer mill blade performance. Daily visual checks can identify early signs of wear, while weekly detailed examinations help detect potential issues before they escalate into major problems. Operators should document blade conditions, noting any unusual wear patterns or damage.

Advanced inspection techniques may include measuring blade thickness, checking for proper alignment, and evaluating edge sharpness. These assessments help determine when rotations or replacements are necessary, preventing unexpected failures during operation.

Wear Pattern Analysis

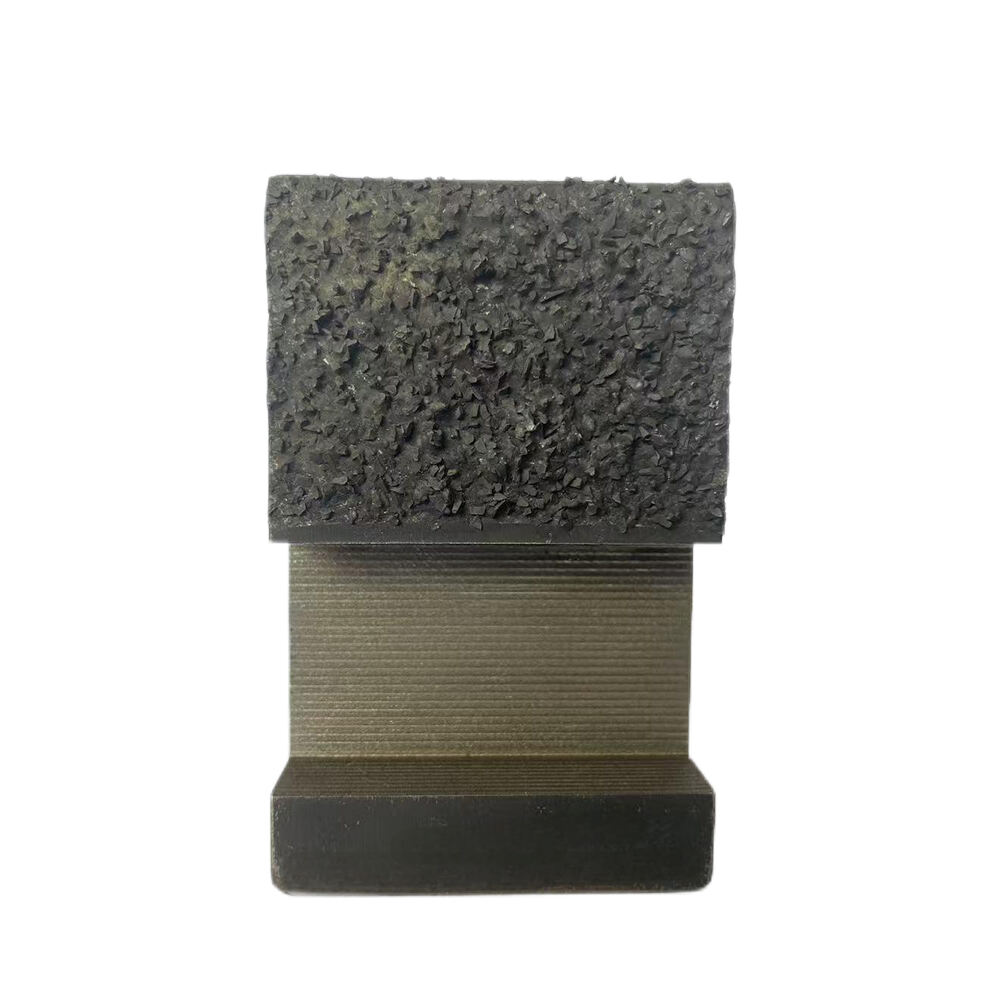

Understanding wear patterns provides valuable insights into optimizing blade life and performance. Different materials and operating conditions create distinct wear characteristics on hammer mill blades. By analyzing these patterns, operators can adjust parameters such as feed rates and rotor speeds to minimize excessive wear.

Documentation of wear patterns also helps in predicting maintenance intervals and identifying potential operational issues. This data-driven approach enables proactive maintenance scheduling and helps prevent catastrophic failures.

Advanced Maintenance Techniques

Proper Cleaning Procedures

Maintaining clean hammer mill blades is essential for optimal performance. Regular cleaning removes material buildup that can affect grinding efficiency and cause imbalances. The cleaning process should follow manufacturer specifications and safety guidelines to prevent damage to the blade surface.

Professional cleaning methods may include pressure washing, chemical cleaning, or mechanical removal of debris. Each technique requires specific safety protocols and proper documentation to ensure consistent application.

Sharpening and Reconditioning

Professional blade sharpening extends service life and maintains grinding efficiency. The process requires specialized equipment and expertise to achieve proper edge angles and surface finish. Reconditioning services can restore worn hammer mill blades to near-original specifications when performed by qualified technicians.

Regular sharpening schedules should be established based on operational demands and material characteristics. This proactive approach helps maintain consistent product quality and reduces energy consumption.

Optimizing Operational Parameters

Feed Rate Management

Proper feed rate control significantly impacts blade wear and overall mill performance. Operators must balance productivity requirements with equipment limitations to achieve optimal results. Monitoring and adjusting feed rates based on material characteristics helps prevent overloading and excessive wear on hammer mill blades.

Implementation of automated feed control systems can help maintain consistent operation and reduce operator error. These systems adjust feed rates based on motor load and other parameters, ensuring optimal blade utilization.

Speed and Impact Force Optimization

Rotor speed and impact force directly affect blade wear and product quality. Finding the right balance requires understanding material properties and desired output specifications. Regular monitoring and adjustment of these parameters help maintain optimal grinding performance while extending blade life.

Advanced monitoring systems can provide real-time data on operational parameters, enabling quick adjustments to maintain optimal conditions. This technology-driven approach helps maximize efficiency and reduce maintenance requirements.

Preventive Maintenance Scheduling

Maintenance Timeline Development

Creating comprehensive maintenance schedules ensures regular attention to hammer mill blades and associated components. These schedules should account for operational hours, material throughput, and historical wear patterns. Regular review and updating of maintenance timelines help optimize resource allocation and minimize downtime.

Integration of maintenance scheduling with production planning ensures minimal disruption to operations. This coordinated approach helps maintain productivity while ensuring equipment reliability.

Documentation and Record Keeping

Maintaining detailed maintenance records provides valuable data for optimizing blade life and performance. Documentation should include inspection results, maintenance activities, and operational parameters. Analysis of this information helps identify trends and improve maintenance strategies over time.

Digital maintenance management systems can streamline record keeping and provide easy access to historical data. These systems facilitate better decision-making and help justify maintenance investments.

Frequently Asked Questions

How often should hammer mill blades be replaced?

The replacement frequency depends on various factors including material type, operational hours, and grinding requirements. Generally, industrial hammer mill blades should be inspected weekly and replaced when wear exceeds manufacturer specifications or when performance significantly deteriorates. Many facilities establish replacement schedules based on throughput volume or operating hours.

What are the signs of worn hammer mill blades?

Common indicators include increased power consumption, reduced product quality, unusual noise or vibration, and visible wear patterns on the blade surface. Regular monitoring of these factors helps determine optimal replacement timing.

How can blade life be maximized?

Blade life can be extended through proper feed rate control, regular cleaning and maintenance, correct rotor speed settings, and prompt attention to any operational abnormalities. Implementation of a comprehensive maintenance program and proper operator training are essential for maximizing blade longevity.

What safety measures should be followed during blade maintenance?

Safety protocols include proper lockout/tagout procedures, use of appropriate personal protective equipment, following manufacturer guidelines for handling and storage, and ensuring only trained personnel perform maintenance tasks. Documentation of safety procedures and regular safety training are crucial components of any maintenance program.