pellet grinder

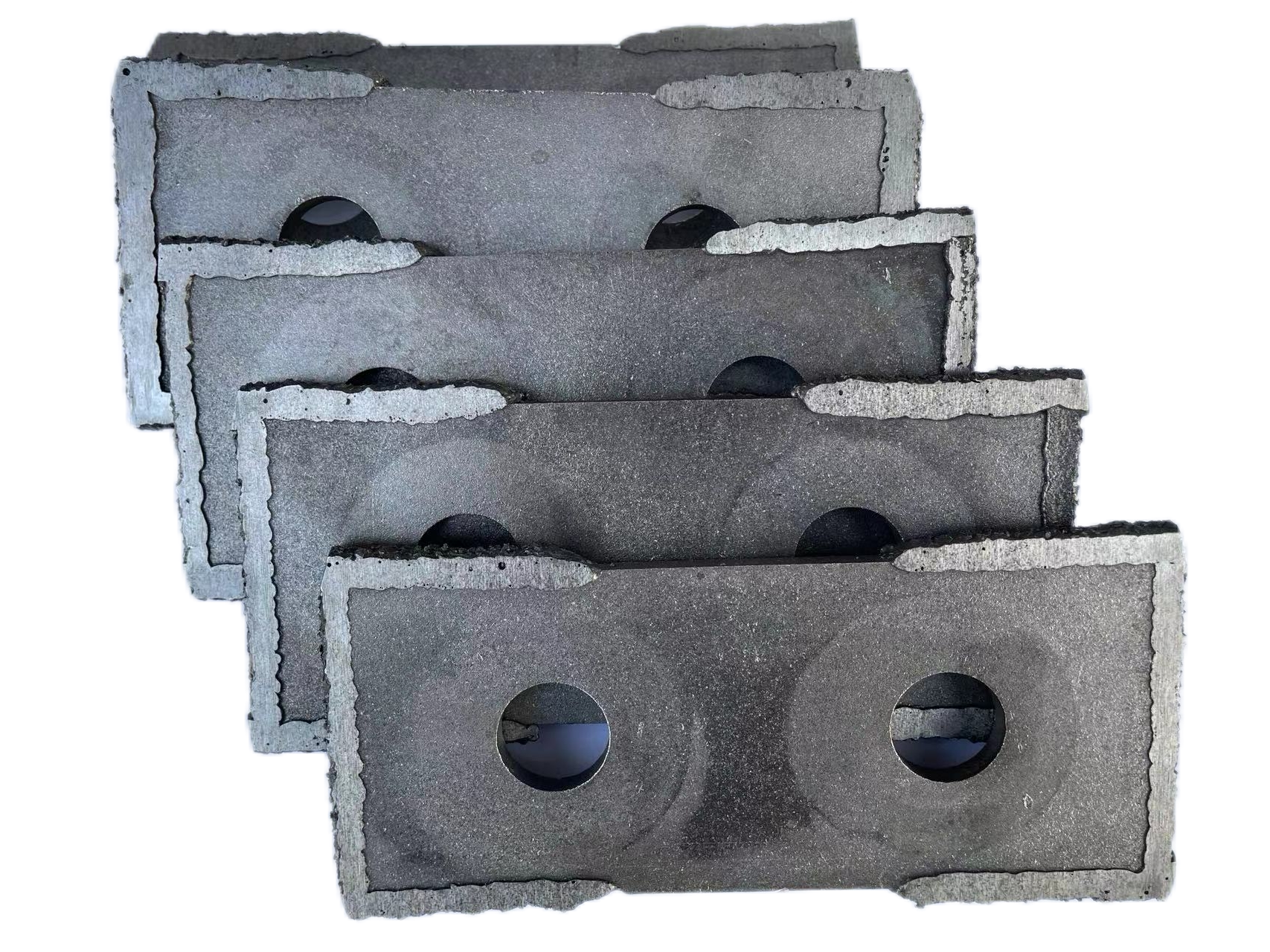

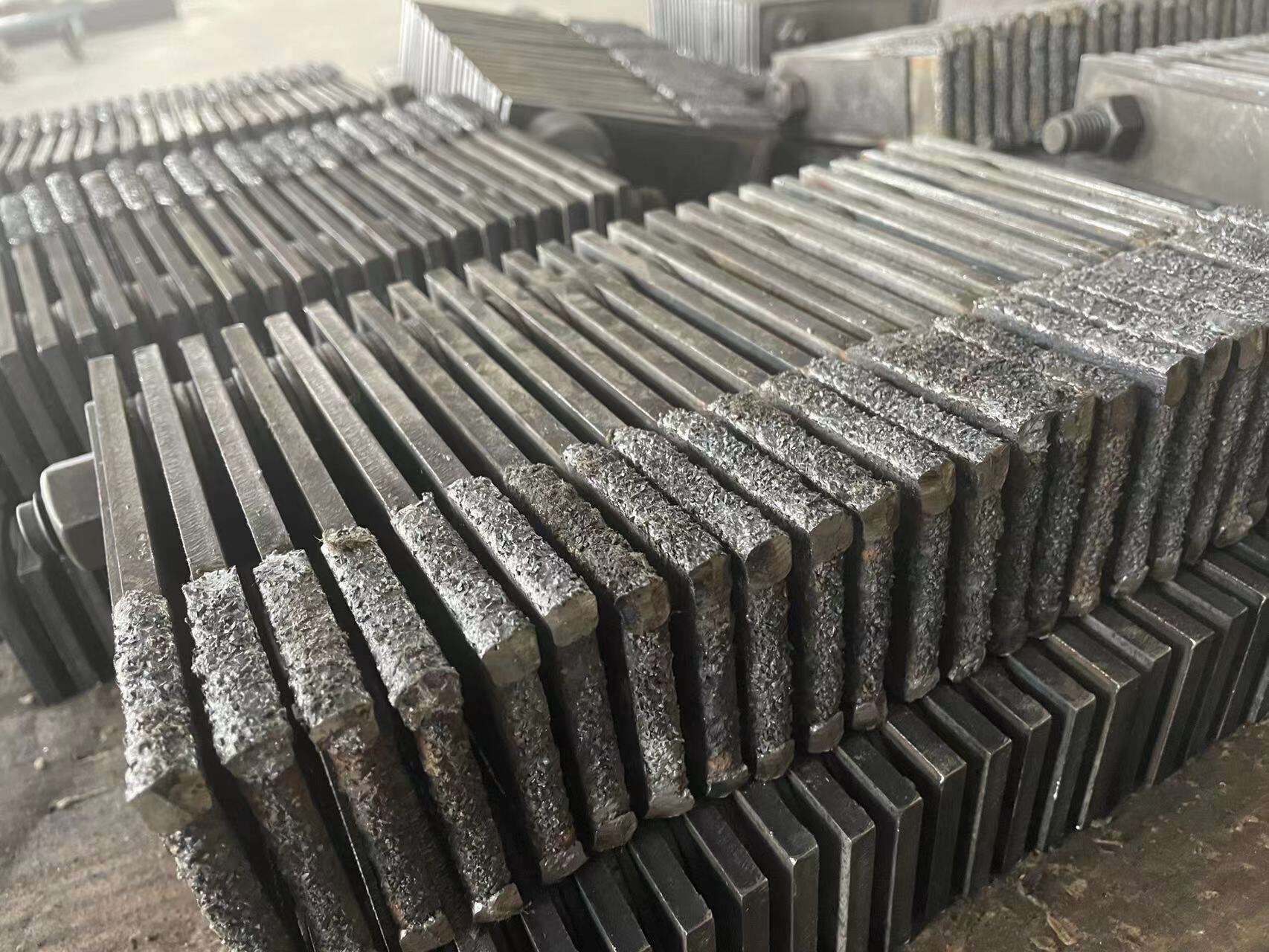

A pellet grinder is a sophisticated piece of equipment designed to efficiently process and reduce various materials into uniform, fine particles. This versatile machine utilizes advanced grinding mechanisms, typically incorporating hardened steel blades or rollers, to break down pellets into consistent sizes. The equipment features precision-engineered components that work in harmony to deliver optimal grinding performance while maintaining material integrity. The grinder's robust construction allows it to handle different types of pellets, from wood and feed to plastic and biomass materials. Modern pellet grinders are equipped with adjustable settings for particle size control, enabling operators to achieve specific output requirements. The machine's feeding system is designed for continuous operation, with safety features that prevent overloading and ensure smooth material flow. Many models include digital controls for precise operation management and monitoring of grinding parameters. The system's efficiency is enhanced by integrated screening mechanisms that ensure uniformity in the final product, while dust collection systems maintain a clean working environment. These machines are invaluable in various industries, including animal feed production, biomass processing, recycling operations, and pharmaceutical manufacturing, where consistent particle size is crucial for product quality.