chicken feed milling machine

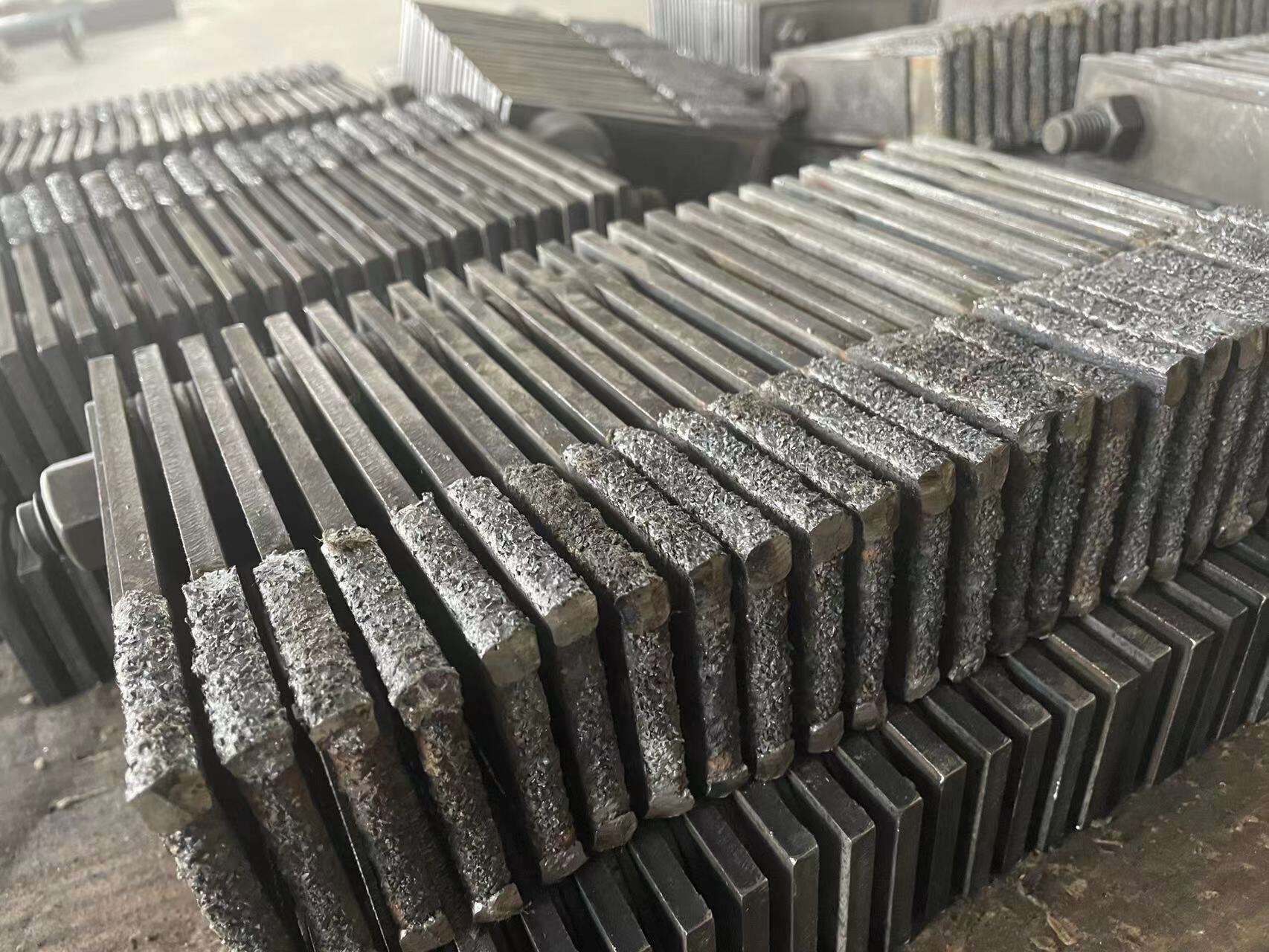

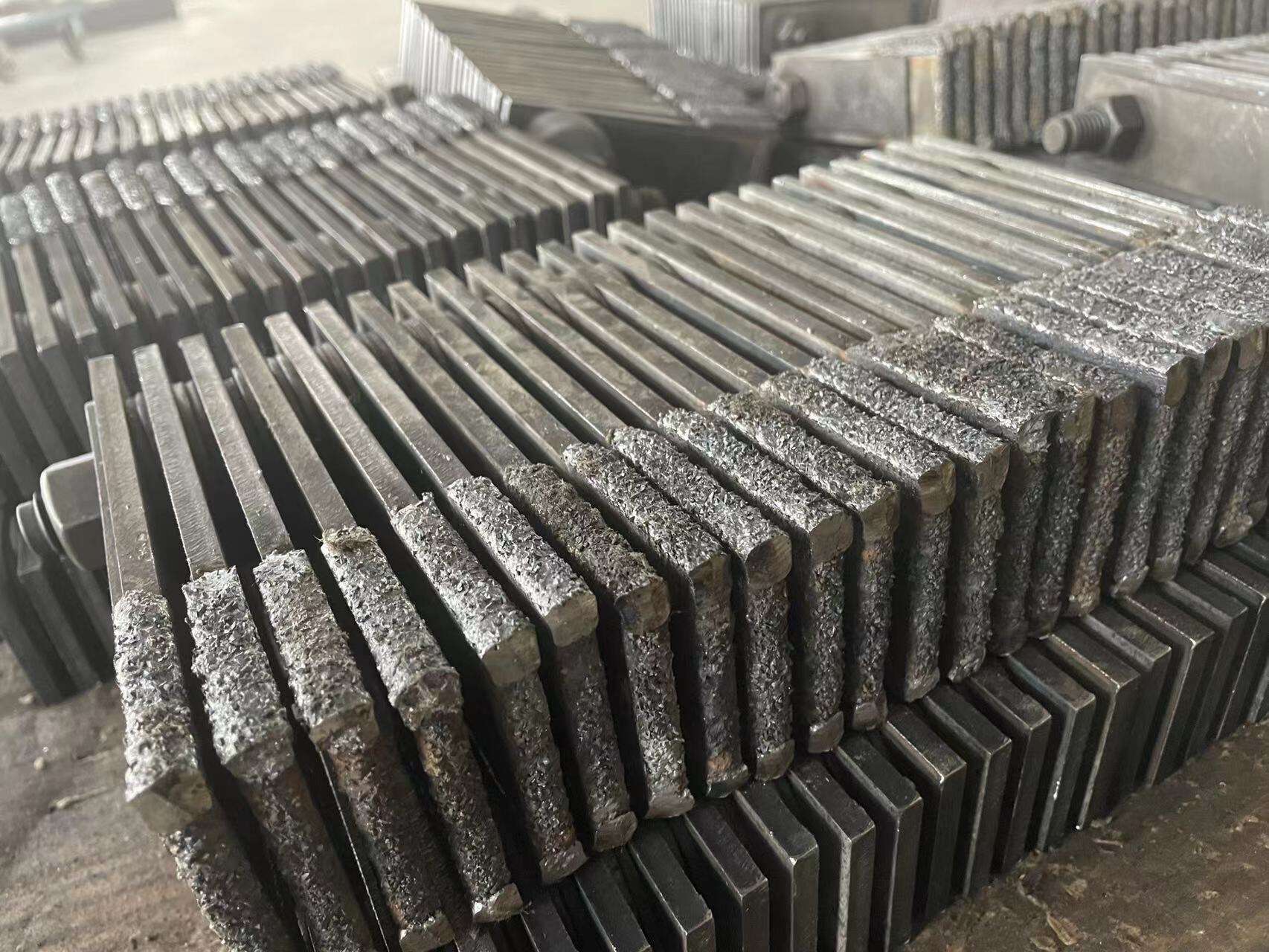

The chicken feed milling machine is an advanced agricultural processing equipment designed to efficiently produce high-quality feed for poultry operations. This versatile machine integrates multiple functions including grinding, mixing, and processing various raw materials into uniform feed particles. The system employs a sophisticated hammer mill mechanism that can process corn, soybean, wheat, and other grains into precisely sized particles. The machine features adjustable grinding specifications, allowing operators to customize feed consistency according to different growth stages of chickens. Its automatic feeding system ensures continuous operation while maintaining consistent output quality. The machine incorporates advanced safety features, including overload protection and emergency stop mechanisms, ensuring operator safety and equipment longevity. With production capacities ranging from 1 to 5 tons per hour, it caters to both small-scale farms and commercial operations. The stainless steel construction guarantees durability and meets food safety standards, while the sealed bearing system minimizes maintenance requirements. Additionally, the machine's energy-efficient motor reduces operational costs while maintaining optimal performance. The integrated control panel offers user-friendly operation, allowing precise adjustment of processing parameters for different feed formulations.