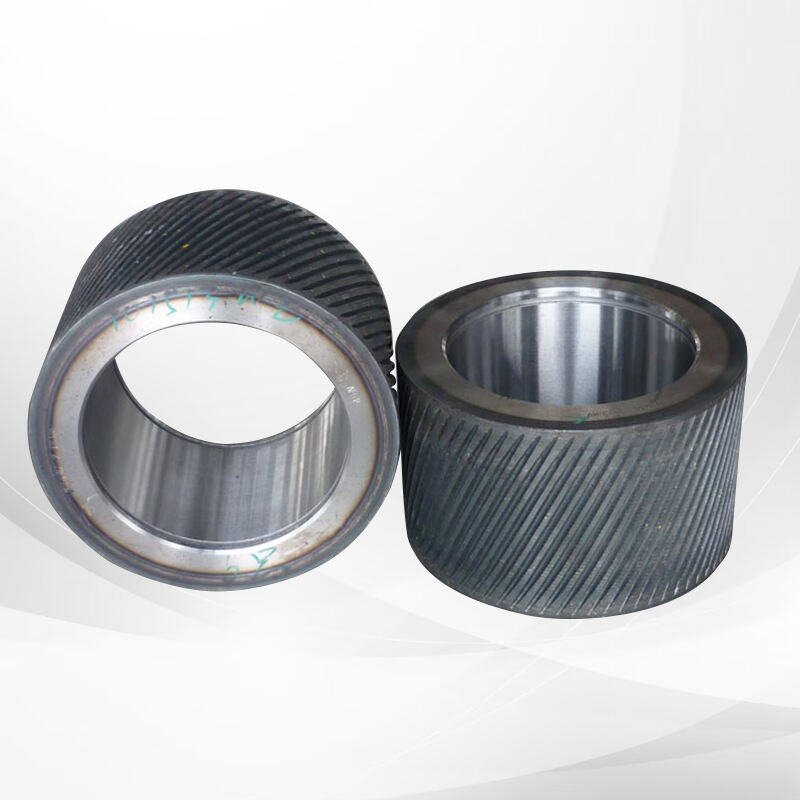

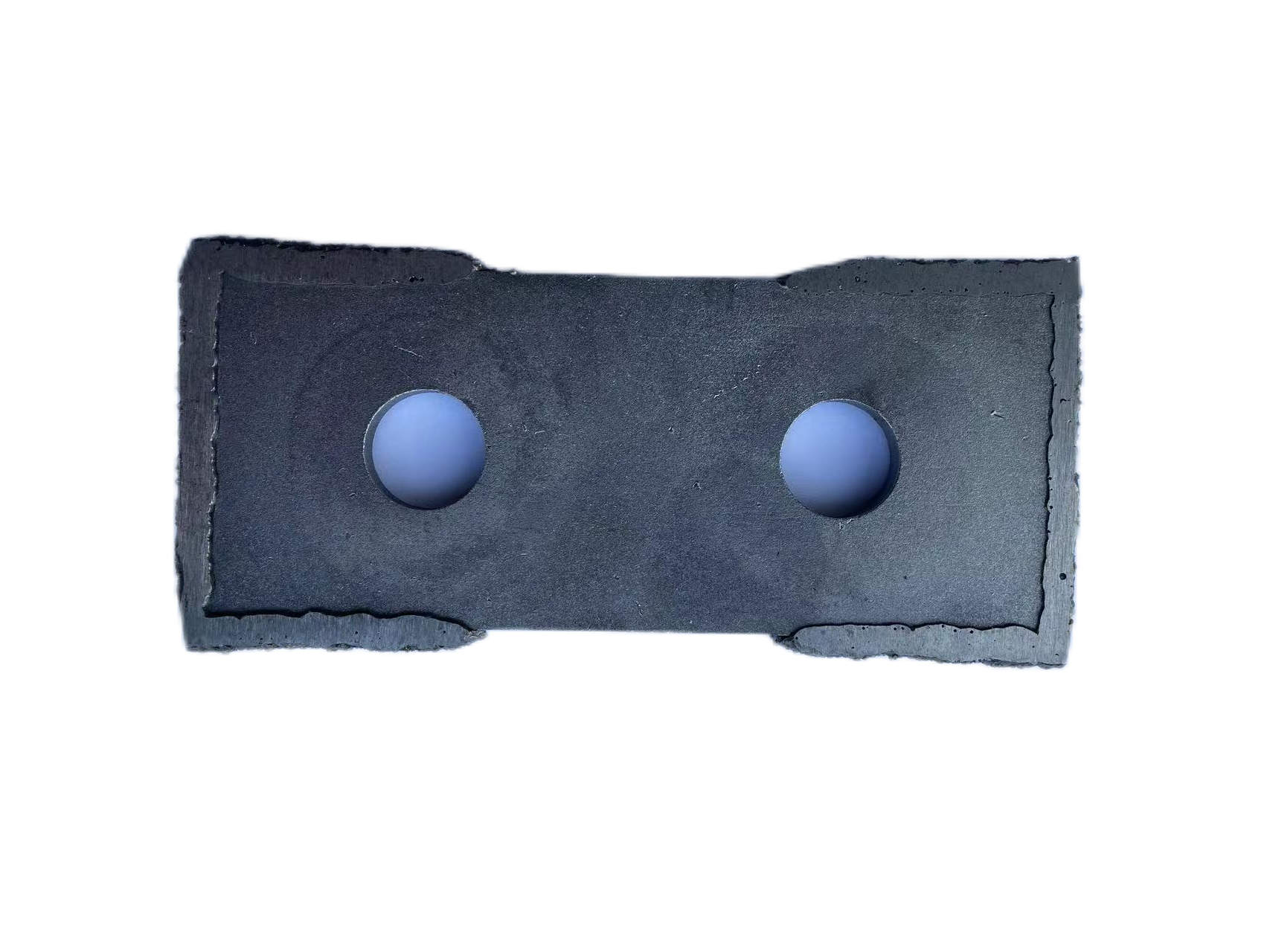

hammer mill beater types

Hammer mill beaters are essential components in size reduction equipment, designed to efficiently process various materials through impact and shearing actions. These beaters come in several types, including swing beaters, rigid beaters, and reversible beaters, each engineered for specific applications. Swing beaters feature a pivoting design that allows them to deflect when encountering uncrushable materials, preventing damage to the mill. Rigid beaters, mounted firmly to the rotor, provide aggressive crushing action ideal for consistent material processing. Reversible beaters offer extended service life by allowing operators to rotate them when one side shows wear. The construction materials vary from high-carbon steel to wear-resistant alloys, depending on the application requirements. Modern hammer mill beaters incorporate advanced metallurgy and precision manufacturing techniques to ensure optimal performance and longevity. These components operate at high speeds within the mill, creating the necessary impact force to reduce material size effectively. The beater design influences factors such as particle size distribution, throughput capacity, and energy efficiency of the milling operation.