best hammer mill beater

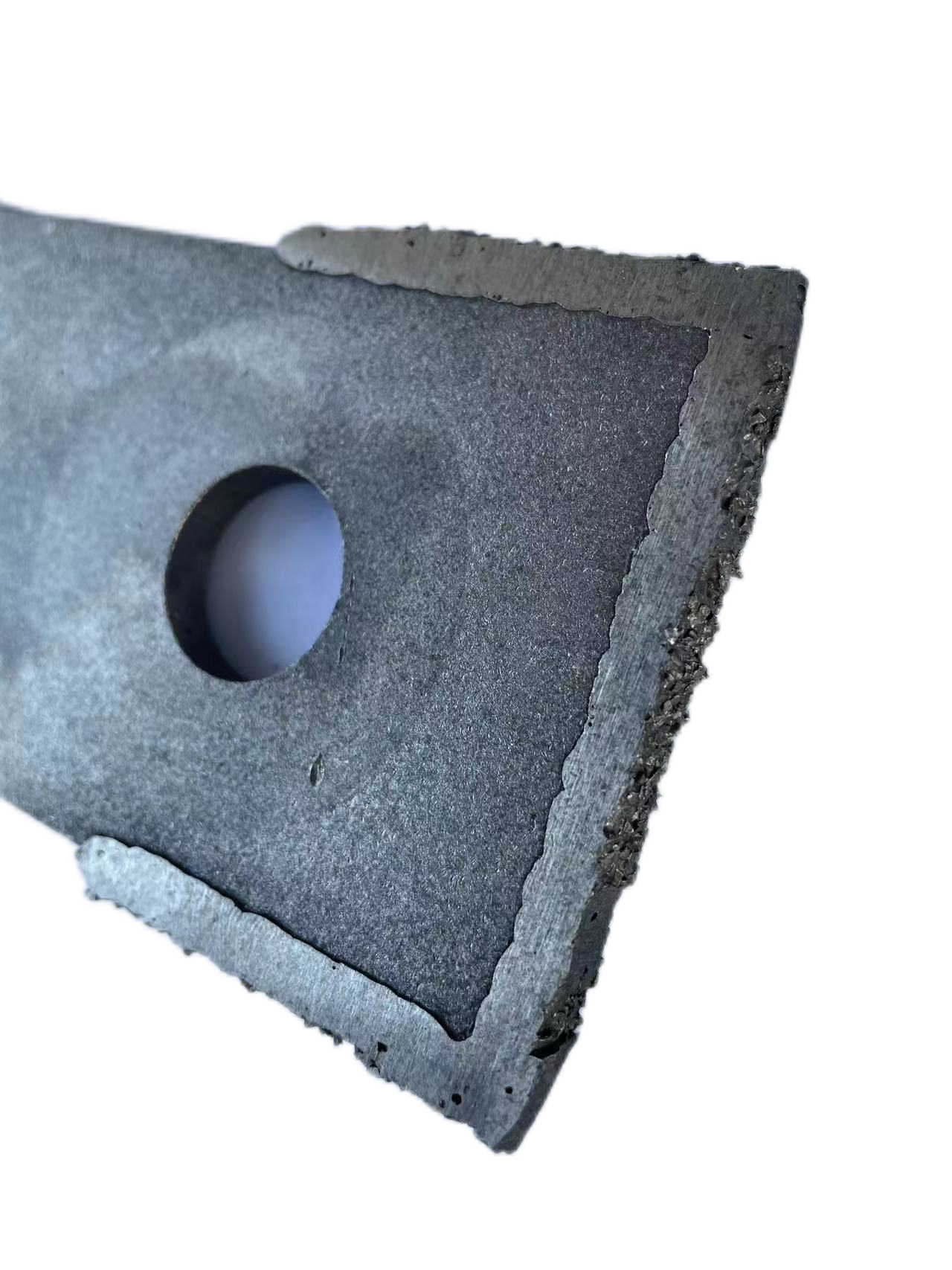

The best hammer mill beater represents a pinnacle of industrial grinding technology, engineered to deliver superior performance in size reduction operations. This essential component features hardened steel construction with precision-engineered striking surfaces that optimize material processing efficiency. The beater's innovative design incorporates advanced wear-resistant alloys, ensuring extended operational life even under demanding conditions. Its carefully calculated weight distribution and balanced construction minimize vibration while maximizing impact force, resulting in consistent particle size reduction. The beater's unique geometry allows for optimal material flow through the mill, preventing clogging and ensuring continuous operation. With customizable mounting options and adjustable positioning, these beaters can be fine-tuned for specific applications ranging from agricultural processing to industrial mineral grinding. The advanced surface treatment technology applied to the beater's impact zones significantly enhances durability and maintains grinding efficiency over extended periods. Compatible with various hammer mill configurations, these beaters demonstrate versatility in processing different materials, from soft organic matter to harder minerals, while maintaining precise size control and uniform output quality.