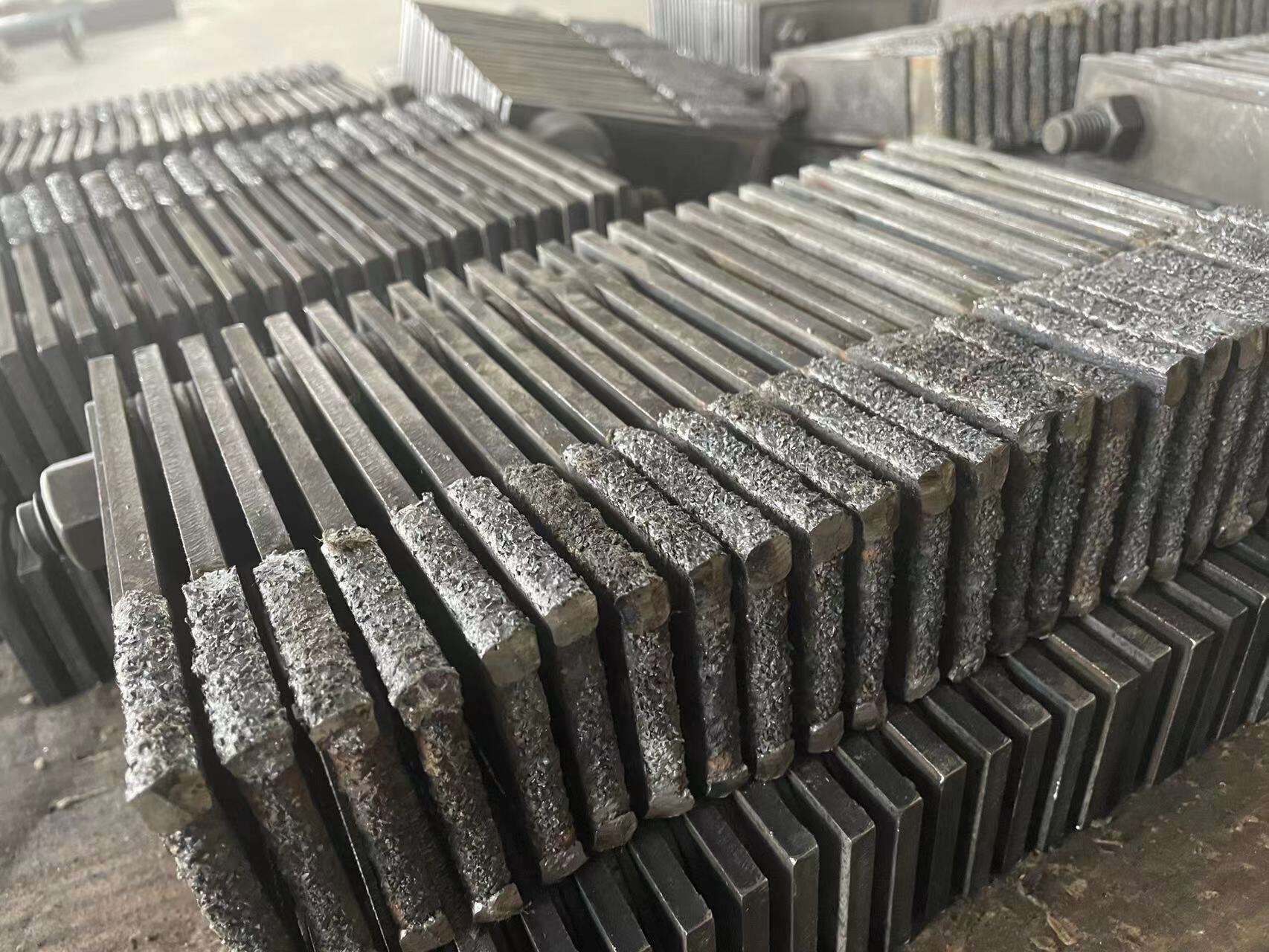

high quality hammer mill beater

The high quality hammer mill beater represents a pinnacle of industrial grinding technology, engineered to deliver exceptional performance in size reduction applications. This robust component features precision-engineered hammers made from wear-resistant alloy steel, specifically designed to withstand continuous high-impact operation. The beater assembly incorporates advanced geometric designs that optimize material flow and enhance grinding efficiency. Each hammer is carefully balanced and mounted on a high-strength rotor shaft, ensuring smooth operation at high speeds while minimizing vibration. The system's innovative design allows for precise clearance adjustment between the hammers and grinding chamber, enabling operators to maintain consistent particle size output. Notable features include replaceable wear plates, hardened impact surfaces, and strategic positioning of the hammers to maximize grinding effectiveness. The hammer mill beater excels in processing various materials, from minerals and chemicals to agricultural products and waste materials, making it an versatile solution for diverse industrial applications. Its construction prioritizes both durability and maintenance accessibility, with easy-to-replace wear components and simplified servicing requirements.