hammer mill beaters material

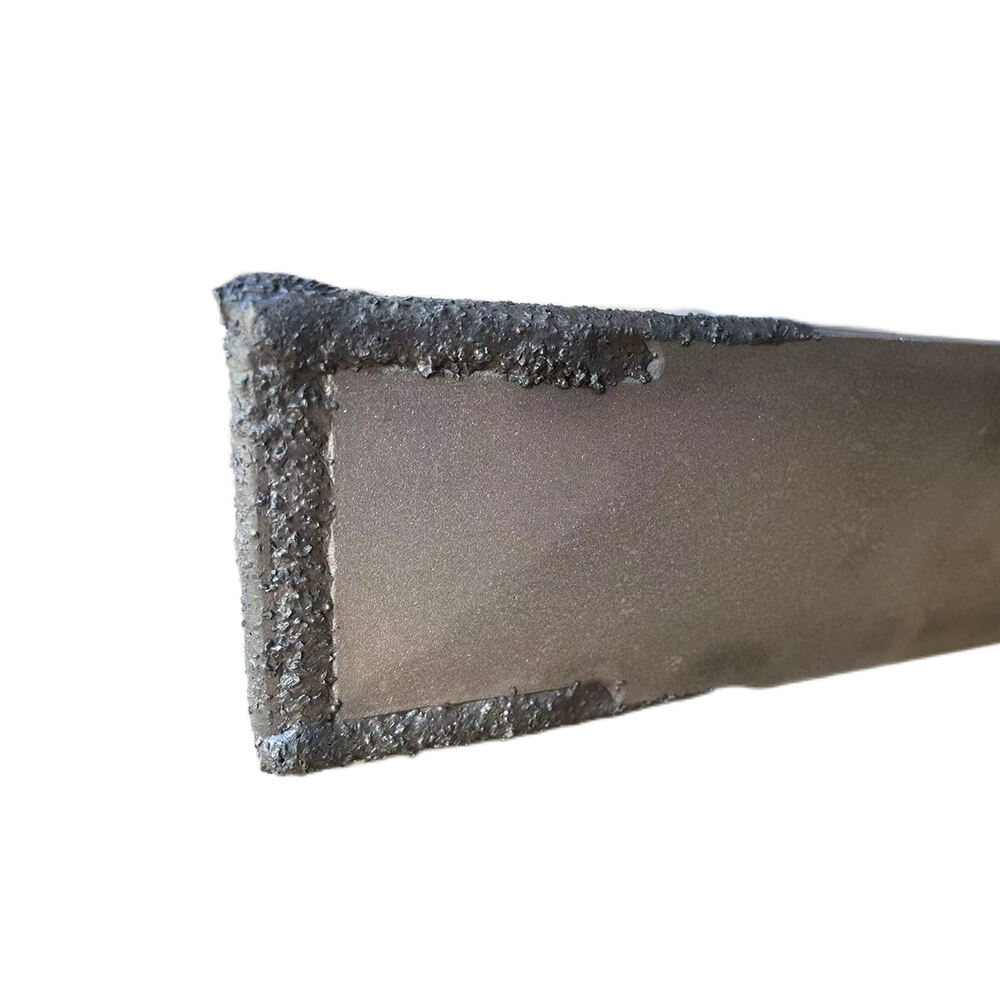

Hammer mill beaters material represents a crucial component in industrial grinding and size reduction equipment. These specialized materials are engineered to withstand intense mechanical stress and repeated impact forces while maintaining optimal performance. Typically manufactured from high-grade alloy steel or manganese steel, hammer mill beaters are designed to deliver consistent particle size reduction across various applications. The material composition includes carefully selected elements that enhance wear resistance, impact strength, and overall durability. These materials undergo specific heat treatment processes to achieve the desired hardness and toughness balance. Modern hammer mill beaters incorporate advanced metallurgical technologies that significantly extend their service life while maintaining efficient grinding performance. The material selection considers factors such as operational temperature, moisture content, and the nature of materials being processed. With proper material selection and treatment, these components can effectively handle diverse materials ranging from agricultural products to minerals. The surface characteristics of the beater material are optimized to prevent material build-up and ensure consistent grinding performance. Additionally, the material properties are carefully balanced to provide both wear resistance and impact resistance, essential for maintaining productive operation in demanding industrial environments.