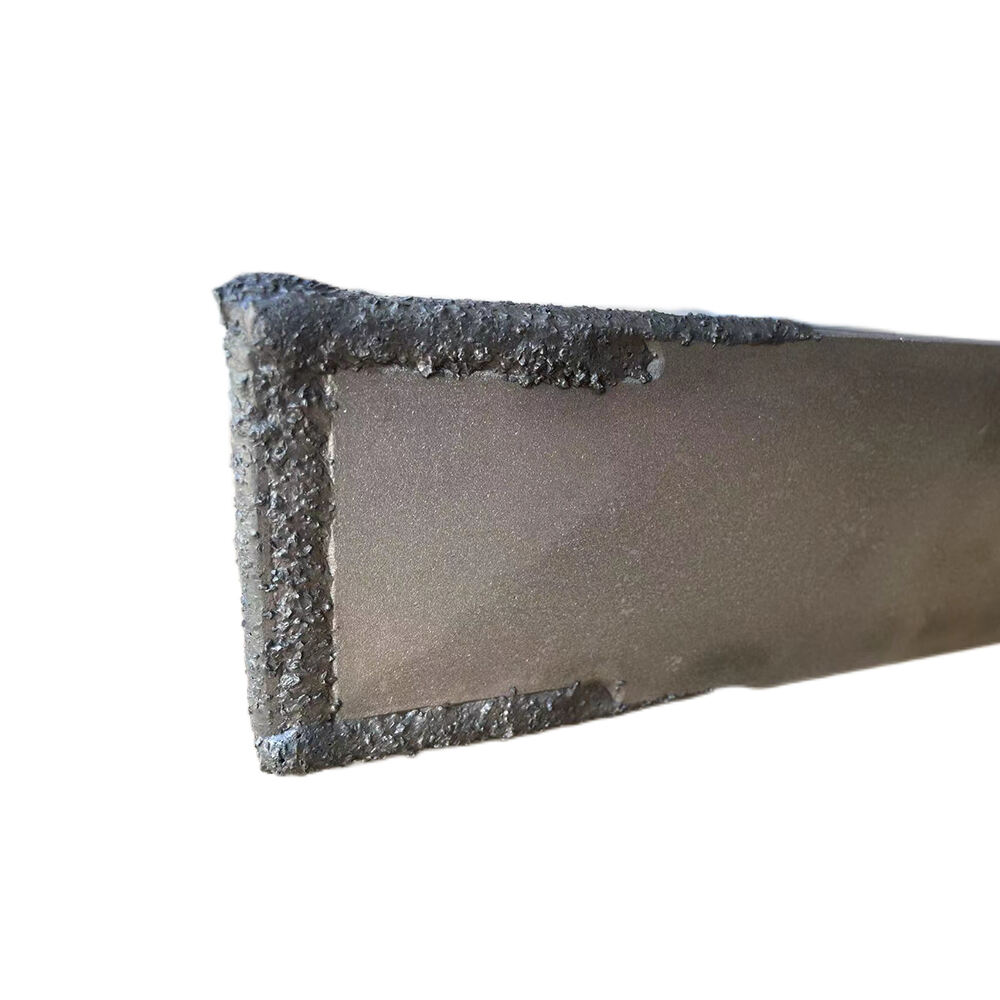

customized ring die

A customized ring die represents a crucial component in pellet production systems, engineered to meet specific manufacturing requirements. This precision-engineered tool features a cylindrical shape with precisely drilled holes that determine the final dimensions and quality of pellets. The ring die's customization allows for variations in hole diameter, length-to-diameter ratio, hole pattern, and surface treatments to optimize performance for different materials and production needs. The die's design incorporates advanced metallurgical properties to ensure durability and consistent output quality, while its customizable compression ratio helps maintain ideal density in the final product. Modern manufacturing techniques enable the integration of special surface treatments and coatings that enhance wear resistance and extend operational lifespan. The die's working surface is carefully engineered to maintain optimal temperature during operation, crucial for achieving proper material extrusion and pellet formation. Applications span across various industries, including animal feed production, biomass processing, and chemical industry pelletization, where specific material characteristics demand unique die configurations. The customization options extend to the entry angle of holes, counterboring specifications, and relief patterns, all of which contribute to improved production efficiency and product quality.