ring die for sale

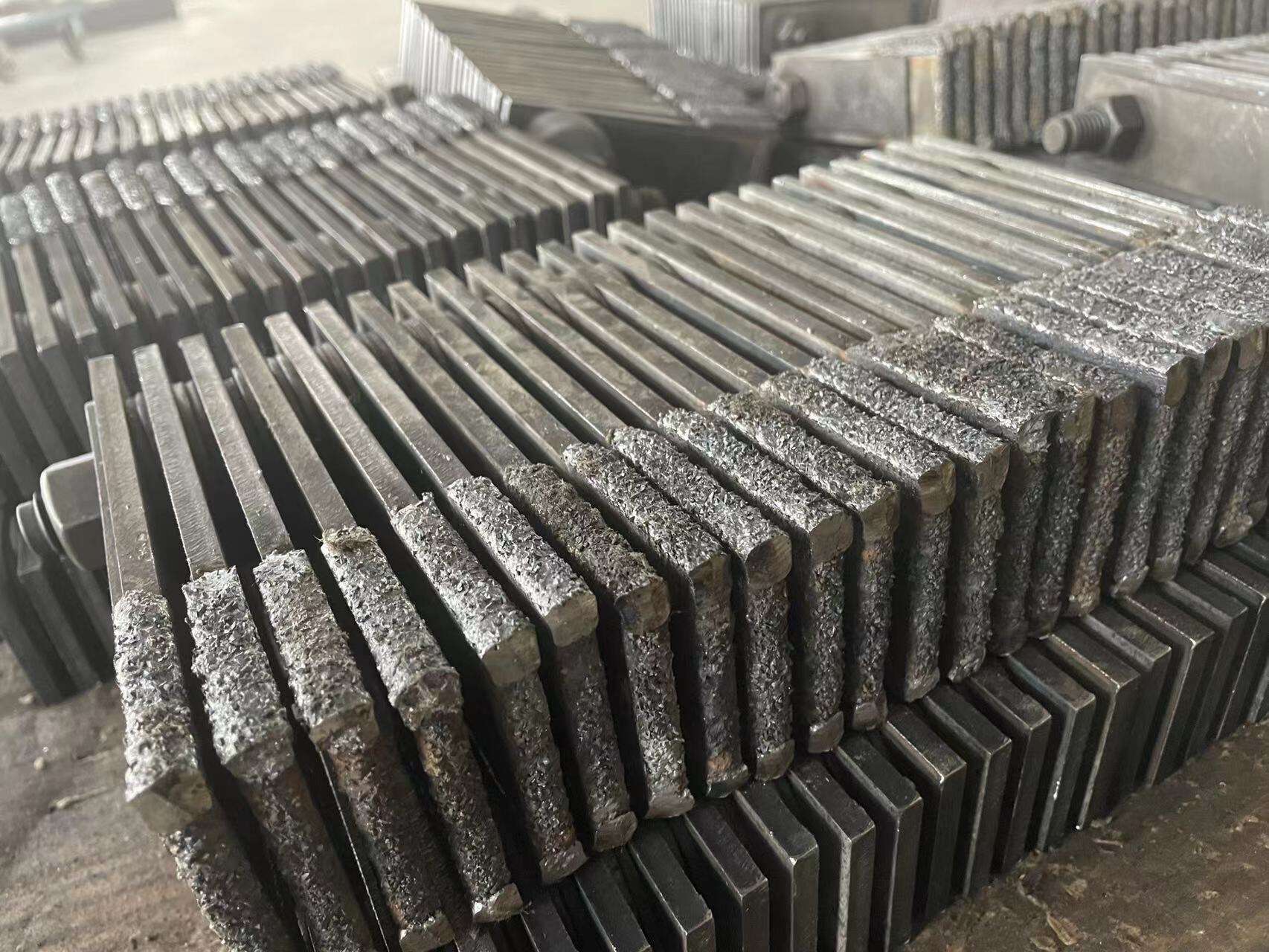

A ring die for sale represents a crucial component in pellet production machinery, engineered with precision to deliver optimal performance in various pelleting applications. This essential equipment features a cylindrical structure with multiple perforation holes arranged in specific patterns, designed to facilitate efficient material compression and extrusion. The ring die is manufactured using premium-grade stainless steel, ensuring durability and resistance to wear and corrosion. Its sophisticated design incorporates advanced metallurgical processes that enhance its longevity and performance capabilities. The die's surface is precisely machined to maintain consistent hole diameter and spacing, crucial for producing uniform pellets. These dies are available in various specifications, with customizable hole sizes, patterns, and thickness ratios to accommodate different raw materials and production requirements. The technology employed in modern ring dies includes advanced heat treatment processes that significantly improve their wear resistance and structural integrity. Whether used in biomass, feed, or other pelleting applications, these ring dies are engineered to maintain high throughput rates while ensuring product quality and consistency. The design also features optimized compression ratio calculations that help achieve the perfect balance between productivity and pellet quality, making it an invaluable tool for various industrial pelleting operations.