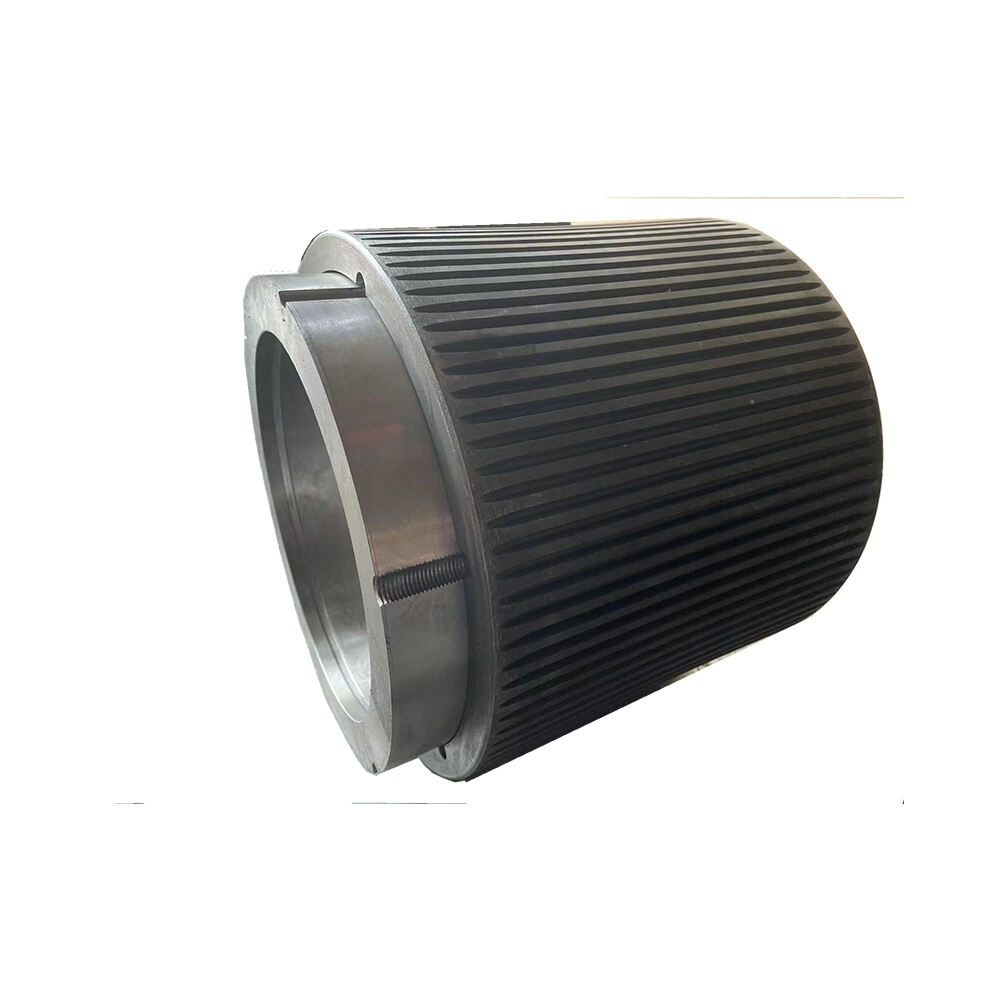

hammer mill blade

The hammer mill blade is a crucial component in industrial grinding and size reduction equipment, designed to efficiently process various materials into smaller, uniform particles. These hardened steel blades, mounted on a high-speed rotor, create powerful impact forces that break down materials through a combination of crushing, shearing, and attrition. The blades feature precision-engineered cutting edges that maintain their sharpness over extended periods, ensuring consistent particle size reduction. Operating at speeds typically ranging from 2,000 to 3,600 RPM, these blades work in conjunction with a screened chamber that controls the final particle size. The design incorporates specialized metallurgy and heat treatment processes to enhance durability and wear resistance, making them suitable for processing everything from grains and biomass to minerals and waste materials. The blade configuration can be customized based on specific application requirements, with options including swing, fixed, or reversible designs. Modern hammer mill blades often feature advanced coating technologies that extend service life and improve performance in demanding applications. The systematic arrangement of multiple blades on the rotor creates an efficient grinding pattern that maximizes throughput while minimizing energy consumption.