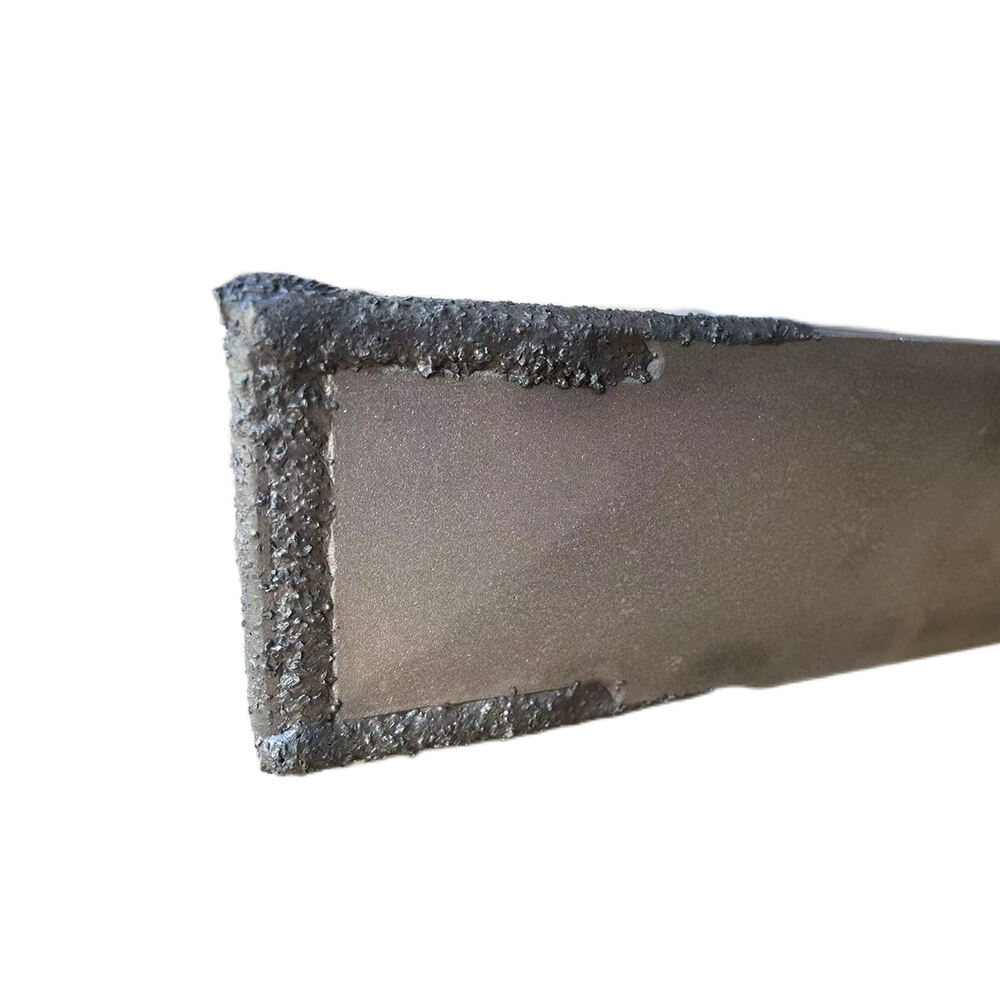

low cost hammer mill blade

The low cost hammer mill blade represents a significant advancement in industrial grinding technology, offering an economical solution without compromising on performance. This essential component features high-grade steel construction with precision-engineered cutting edges designed for optimal material reduction. The blade's unique geometry ensures efficient particle size reduction while minimizing energy consumption. Operating at various speeds, these blades effectively process materials ranging from agricultural products to industrial waste. The specialized heat treatment process enhances durability, resulting in extended service life despite their affordable price point. These blades are compatible with most standard hammer mill models, making them a versatile choice for diverse industrial applications. The innovative design incorporates wear-resistant properties that maintain sharp cutting edges throughout extended operation periods. With precise manufacturing tolerances, these blades ensure consistent particle size distribution, crucial for quality control in processing operations. The cost-effective nature of these blades makes them particularly attractive for small to medium-sized operations looking to optimize their grinding processes while maintaining budget constraints.