top rated hammer mill blade

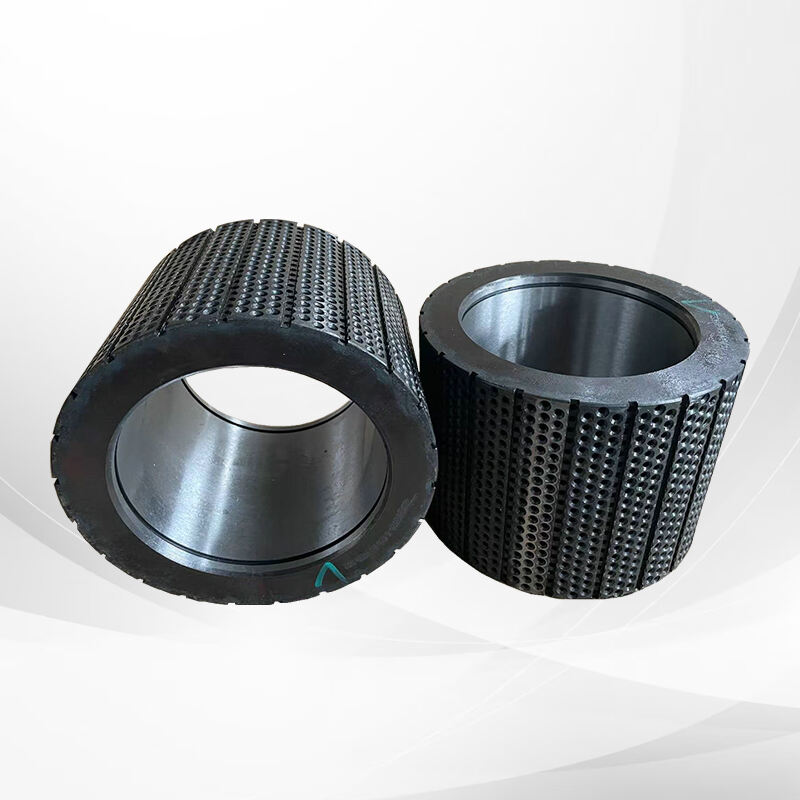

The top rated hammer mill blade represents the pinnacle of industrial grinding technology, engineered to deliver exceptional performance and durability in material reduction applications. This premium blade features high-grade alloy steel construction with advanced heat treatment processes, ensuring optimal hardness and wear resistance. The precision-engineered cutting edges maintain their sharpness through extended operational periods, while the specialized geometry facilitates efficient material flow and consistent particle size reduction. The blade's innovative design incorporates reinforced stress points and balanced weight distribution, minimizing vibration and extending equipment lifespan. Suitable for various industries including agriculture, mining, and recycling, these blades excel in processing diverse materials from grains to minerals. The sophisticated manufacturing process includes computer-aided design and rigorous quality control measures, resulting in blades that maintain consistent performance under demanding conditions. With a working life significantly longer than standard alternatives, these blades offer superior return on investment while reducing maintenance downtime.