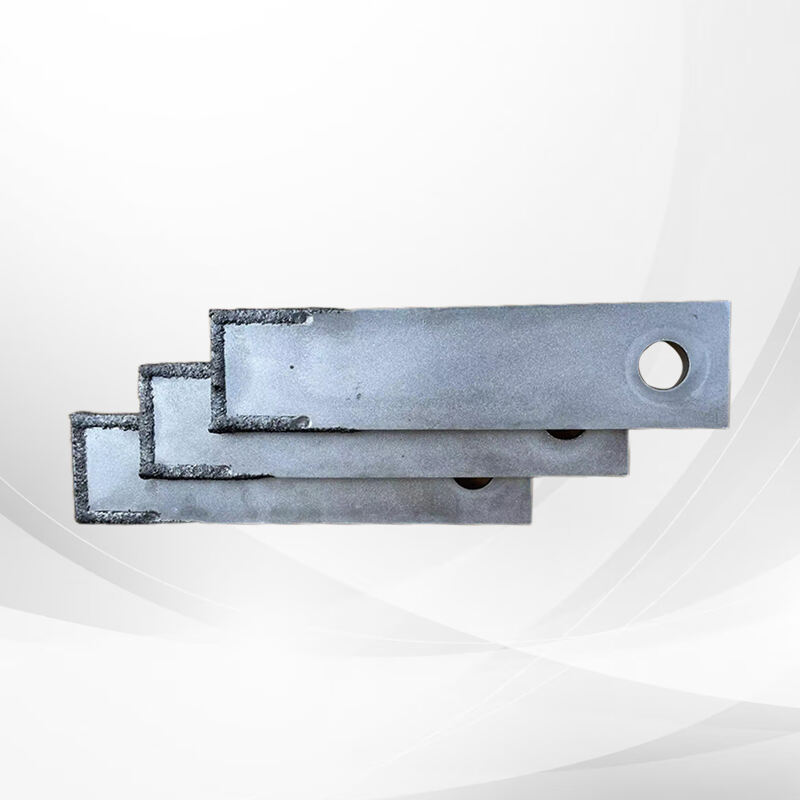

discount hammer mill blade

The discount hammer mill blade represents a cost-effective solution for industrial grinding and size reduction operations. This essential component features high-grade steel construction with precision-engineered cutting edges designed to deliver optimal performance in various milling applications. The blade's innovative design incorporates wear-resistant materials that extend its operational lifespan while maintaining consistent grinding efficiency. These blades are specifically engineered to work seamlessly with standard hammer mill equipment, offering exceptional particle size reduction capabilities for materials ranging from grains to biomass. The blade's unique geometry ensures efficient impact force distribution, reducing energy consumption while maintaining high throughput rates. Each blade undergoes strict quality control measures, including heat treatment processes that enhance durability and maintain sharp cutting edges over extended periods. The discount pricing model makes these high-quality blades accessible to operations of all sizes without compromising on performance or reliability. These blades are particularly suitable for agricultural processing, waste reduction, and various industrial applications where consistent particle size reduction is crucial.