new hammer mill blade

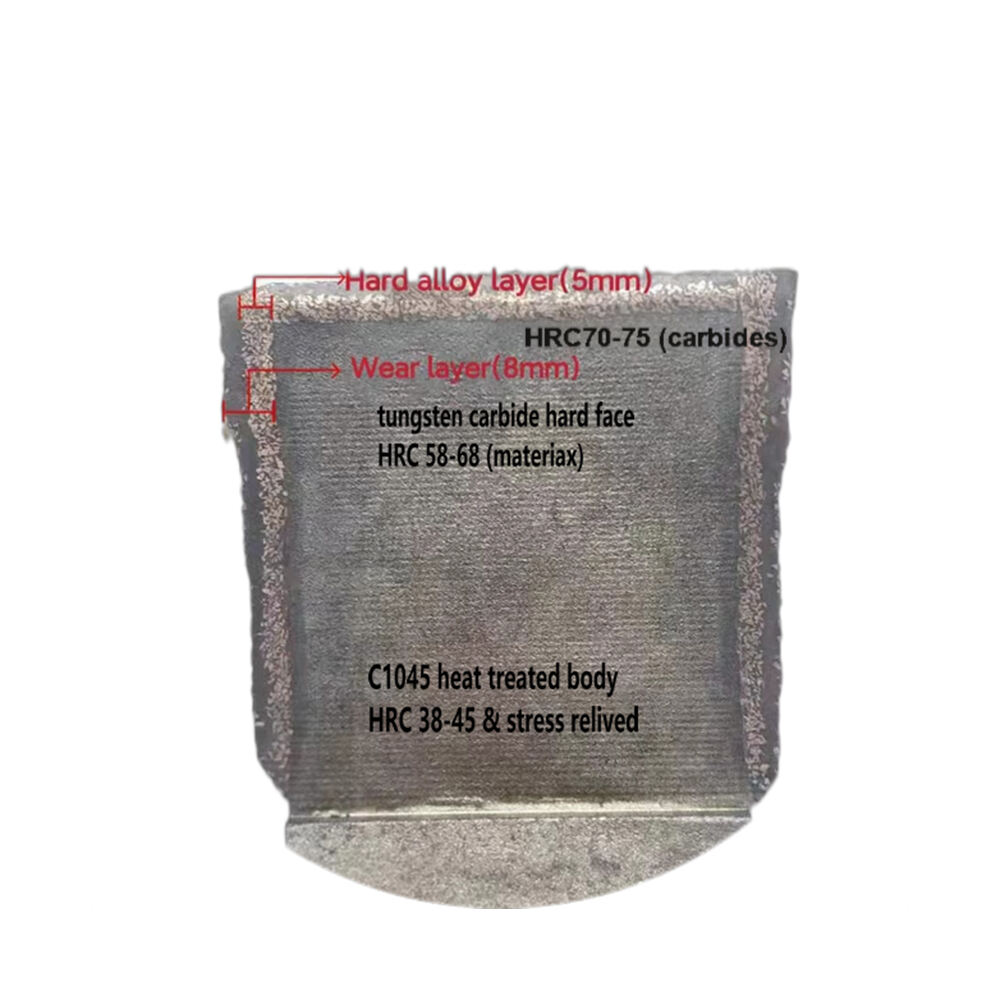

The new hammer mill blade represents a significant advancement in industrial grinding technology, combining innovative design with superior performance characteristics. This cutting-edge blade features precision-engineered hardened steel construction, incorporating advanced wear-resistant coatings that substantially extend its operational lifespan. The blade's unique geometric design optimizes impact force distribution, enabling more efficient particle size reduction while minimizing energy consumption. With its reversible cutting edges, operators can maximize blade utilization before replacement becomes necessary. The blade's enhanced durability comes from its specialized heat treatment process, which creates a consistently hardened surface while maintaining core toughness. Its innovative mounting system allows for quick replacement and precise positioning, reducing maintenance downtime significantly. The blade is specifically designed to handle various materials, from agricultural products to industrial minerals, maintaining consistent particle size distribution across different applications. Advanced computer modeling has optimized the blade's angle and configuration to reduce wear patterns and improve material flow through the mill, resulting in more uniform end products and reduced operating costs.