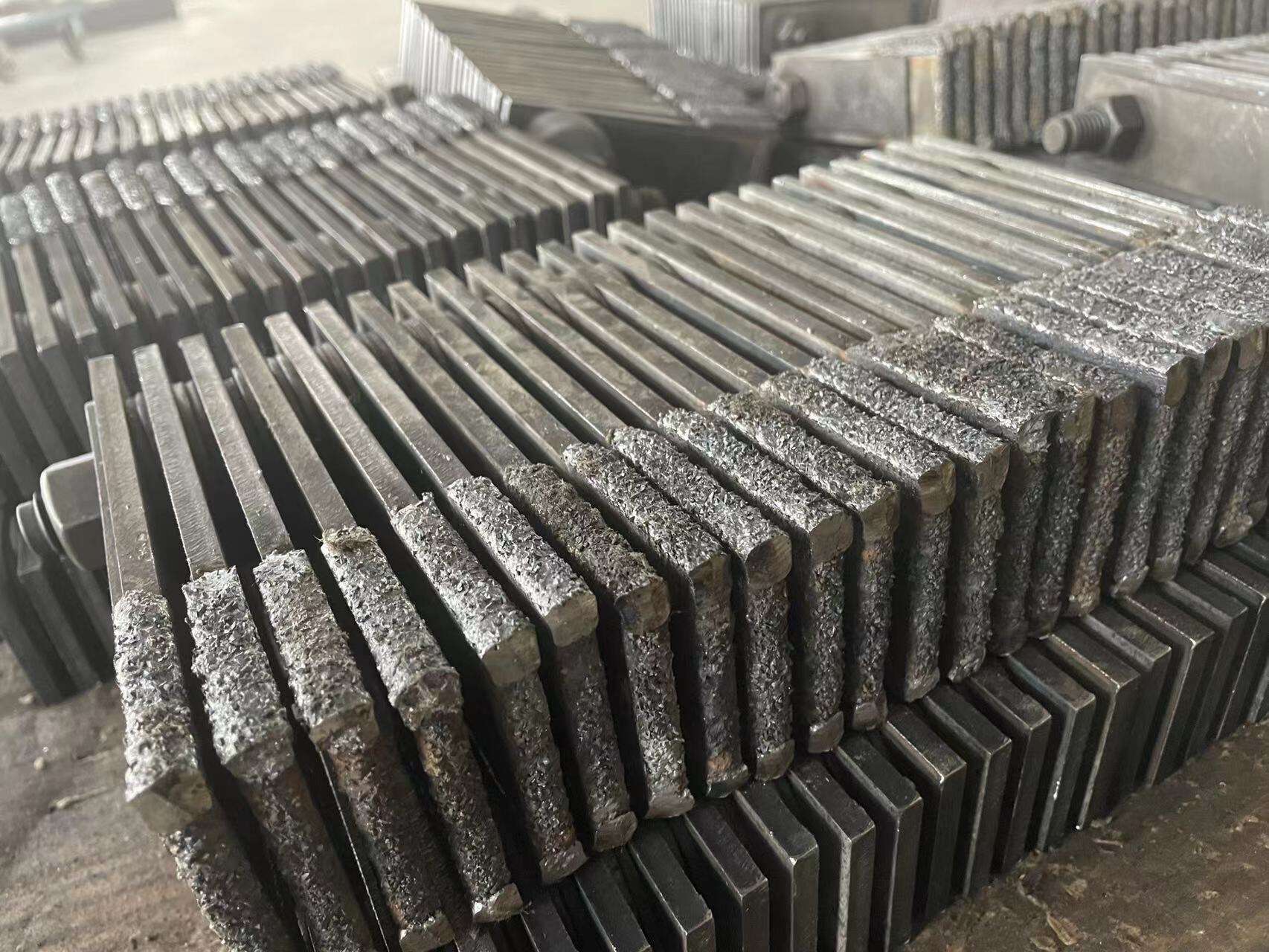

stable hammer mill blade

The stable hammer mill blade represents a crucial component in modern grinding and size reduction equipment, engineered to deliver consistent particle size reduction across various industrial applications. This precision-engineered blade features high-grade alloy steel construction, specifically designed to withstand intense impact forces while maintaining structural integrity throughout extended operational periods. The blade's stability comes from its balanced design and precise weight distribution, which minimizes vibration during high-speed rotation. Key technological features include heat-treated surfaces for enhanced durability, precision-ground edges for optimal cutting efficiency, and specialized mounting points that ensure secure attachment to the mill rotor. The blade's geometry is optimized to create the ideal impact angle for material processing, whether dealing with grains, minerals, or other materials requiring size reduction. In industrial settings, these blades operate at speeds of up to 3,600 RPM, efficiently processing materials while maintaining consistent particle size output. The design incorporates advanced wear-resistant properties, significantly extending the blade's service life and reducing maintenance frequency. Applications span across multiple industries, including agriculture, mining, recycling, and biomass processing, where reliable and precise material reduction is essential for operational efficiency.