Proper maintenance of hammermill beater systems is crucial for maintaining optimal grinding performance and extending equipment lifespan in industrial operations. These robust components endure tremendous stress during high-speed material processing, making regular upkeep essential for preventing costly downtime and ensuring consistent output quality. Understanding the fundamental principles of hammermill beater care enables operators to maximize efficiency while minimizing operational costs.

Essential Pre-Operation Inspection Procedures

Visual Assessment of Beater Components

Before starting any hammermill operation, conducting thorough visual inspections prevents unexpected failures and maintains processing efficiency. Examine each beater element for signs of excessive wear, cracking, or deformation that could compromise performance. Pay particular attention to mounting hardware, ensuring all bolts and pins remain tight and properly secured. Document any abnormalities discovered during inspection to establish maintenance patterns and predict future replacement needs.

Check the rotor assembly for proper alignment and balance, as misaligned components create vibration issues that accelerate wear throughout the entire system. Look for accumulated material buildup around beater edges that might affect grinding uniformity or create imbalanced loading conditions. Regular photographic documentation helps track component degradation over time and supports evidence-based maintenance scheduling decisions.

Clearance Measurements and Adjustments

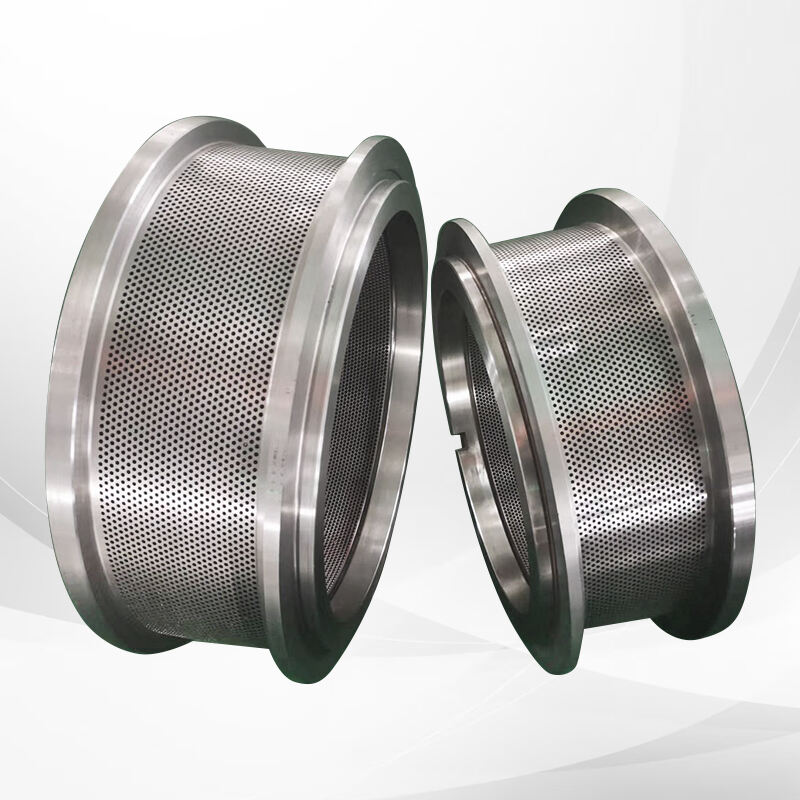

Accurate clearance measurements between hammermill beater elements and screen surfaces directly impact particle size consistency and energy consumption efficiency. Use precision measuring tools to verify gaps remain within manufacturer specifications, typically ranging from 3 to 12 millimeters depending on application requirements. Excessive clearances allow oversized particles to pass through, while insufficient gaps increase power consumption and accelerate component wear.

Adjust clearances systematically by repositioning screen assemblies or replacing worn beater components as needed. Keep detailed records of adjustment dates and measurements to establish wear patterns specific to your material processing conditions. This data enables predictive maintenance scheduling that prevents unexpected shutdowns and optimizes replacement part inventory management.

Lubrication System Optimization

Bearing Maintenance Protocols

Proper lubrication of hammermill beater bearing assemblies prevents premature failure and maintains smooth operation under high-speed conditions. Follow manufacturer-specified lubrication intervals and use only approved lubricant grades suitable for operating temperatures and speeds encountered in your application. Monitor bearing temperatures regularly using infrared thermometry to detect early signs of lubrication breakdown or contamination.

Implement grease sampling programs for critical bearing locations to assess lubricant condition and contamination levels through laboratory analysis. Replace lubricants immediately when analysis indicates degradation or contamination that could damage bearing surfaces. Maintain detailed lubrication logs documenting dates, quantities, and lubricant types used for each service point.

Seal Integrity Verification

Maintaining effective sealing systems protects internal lubrication from contamination while preventing lubricant leakage that could create safety hazards or environmental concerns. Inspect all seals regularly for signs of wear, cracking, or displacement that might compromise their effectiveness. Replace damaged seals immediately to prevent costly bearing damage from dust infiltration or lubricant loss.

Consider upgrading to advanced sealing technologies when replacing worn components, as modern designs often provide superior protection against harsh operating environments typical of hammermill applications. Verify proper seal installation using manufacturer-provided torque specifications and alignment procedures to ensure optimal performance and longevity.

Balance and Vibration Management

Dynamic Balancing Procedures

Maintaining proper rotor balance prevents excessive vibration that damages bearings, foundations, and surrounding equipment while ensuring consistent hammermill beater performance. Perform dynamic balancing whenever replacing individual beaters or after detecting increased vibration levels during operation. Use precision balancing equipment to identify and correct imbalance conditions that could lead to premature component failure.

Document all balancing work with before and after vibration measurements to verify correction effectiveness and establish baseline values for future reference. Train maintenance personnel in proper balancing techniques to enable in-house corrections for minor imbalances, reducing downtime and external service costs while maintaining optimal operating conditions.

Vibration Monitoring Systems

Installing continuous vibration monitoring systems provides early warning of developing mechanical problems before they cause catastrophic failures. Set alarm thresholds based on historical data and manufacturer recommendations to trigger maintenance actions when vibration levels exceed normal operating ranges. Regular trending analysis helps identify gradual degradation patterns that might not be apparent during routine inspections.

Correlate vibration data with other operating parameters such as power consumption, throughput, and product quality to gain comprehensive insights into equipment health and performance trends. This integrated approach enables optimized maintenance scheduling that balances equipment reliability with operational efficiency requirements.

Screen and Housing Maintenance

Screen Replacement Strategies

Timely screen replacement maintains product quality consistency while preventing damage to hammermill beater components from excessive wear caused by deteriorated screening surfaces. Monitor screen condition through regular thickness measurements and visual inspections for hole enlargement or structural damage. Replace screens when hole sizes exceed specifications or when structural integrity becomes compromised.

Implement systematic screen rotation programs to maximize service life and maintain consistent particle size distribution. Keep detailed records of screen performance including throughput rates, power consumption, and product quality measurements to optimize replacement intervals and screen selection for specific applications.

Housing Alignment Verification

Proper housing alignment ensures optimal clearances between rotating and stationary components while preventing excessive wear from misalignment-induced contact. Use laser alignment tools to verify housing squareness and concentricity according to manufacturer specifications. Correct any alignment issues immediately to prevent accelerated component wear and potential safety hazards from mechanical interference.

Check foundation anchor bolts regularly for looseness that could allow housing movement during operation. Retorque all fasteners to specified values and inspect for signs of fatigue or corrosion that might compromise structural integrity. Maintain accurate alignment records to track any gradual changes that might indicate foundation settling or structural issues requiring attention.

Performance Monitoring and Documentation

Operating Parameter Tracking

Systematic monitoring of key operating parameters provides valuable insights into hammermill beater condition and overall system performance trends. Track power consumption, throughput rates, product fineness, and vibration levels to establish baseline values and identify performance degradation patterns. Use this data to optimize maintenance intervals and predict component replacement needs before failures occur.

Implement automated data collection systems where possible to ensure consistent measurement accuracy and eliminate human error in data recording. Analyze trends regularly to identify correlations between operating conditions and maintenance requirements, enabling proactive adjustments to maintenance schedules and procedures.

Maintenance History Management

Comprehensive maintenance documentation enables informed decision-making regarding component replacement timing, spare parts inventory, and maintenance procedure optimization. Record all maintenance activities including inspection findings, adjustments made, parts replaced, and labor hours required for each task. This information supports accurate cost analysis and helps identify opportunities for efficiency improvements.

Use computerized maintenance management systems to organize and analyze maintenance data effectively. Generate regular reports showing maintenance costs, equipment reliability trends, and parts consumption patterns to support strategic planning and budget development for hammermill operations.

Safety Protocols and Procedures

Lockout Tagout Implementation

Proper lockout tagout procedures protect maintenance personnel from injury during hammermill beater service activities. Develop comprehensive energy isolation procedures covering electrical, mechanical, and pneumatic energy sources that could cause unexpected equipment movement during maintenance. Train all personnel in proper lockout techniques and verify understanding through practical demonstrations and written testing.

Maintain current lockout procedures that reflect actual equipment configurations and energy sources present in your facility. Update procedures whenever modifications are made to equipment or control systems that might affect energy isolation requirements. Regular audits ensure continued compliance with safety regulations and protect personnel from preventable injuries.

Personal Protective Equipment Requirements

Appropriate personal protective equipment selection protects maintenance workers from hazards associated with hammermill beater maintenance activities. Require safety glasses, hearing protection, cut-resistant gloves, and steel-toed footwear for all maintenance work. Provide respiratory protection when working in dusty environments or when using cleaning solvents that might create inhalation hazards.

Establish equipment inspection and replacement schedules to ensure protective equipment remains effective throughout its service life. Train personnel in proper equipment selection, use, and care to maximize protection effectiveness while maintaining comfort and mobility during maintenance tasks.

FAQ

How often should hammermill beater components be inspected for wear

Hammermill beater components should undergo daily visual inspections during normal operation checks, with detailed examinations performed weekly or after every 40-50 operating hours depending on material characteristics and throughput rates. High-abrasion applications may require more frequent inspection intervals to prevent unexpected failures that could damage other system components or create safety hazards.

What are the most common signs of hammermill beater wear that operators should monitor

Key wear indicators include increased vibration levels, rising power consumption for the same throughput, enlarged product particle sizes, visible edge rounding or cracking on beater surfaces, and unusual noise patterns during operation. Monitoring these parameters helps identify developing problems before they cause complete component failure or system damage.

When should hammermill beater clearances be adjusted or components replaced

Adjust clearances when measurements exceed manufacturer specifications by more than 20%, typically indicating significant wear has occurred. Replace beater components when edge thickness decreases beyond minimum specifications, cracks appear in mounting areas, or when continued adjustment cannot maintain proper clearances. Proactive replacement prevents secondary damage to screens and housing components.

What maintenance procedures help extend hammermill beater service life most effectively

Regular lubrication of bearing assemblies, proper rotor balancing after component replacement, maintaining optimal clearances between beaters and screens, and operating within recommended speed and loading parameters significantly extend service life. Additionally, using appropriate beater materials for specific applications and avoiding contamination from foreign objects helps maximize component longevity and system reliability.

Table of Contents

- Essential Pre-Operation Inspection Procedures

- Lubrication System Optimization

- Balance and Vibration Management

- Screen and Housing Maintenance

- Performance Monitoring and Documentation

- Safety Protocols and Procedures

-

FAQ

- How often should hammermill beater components be inspected for wear

- What are the most common signs of hammermill beater wear that operators should monitor

- When should hammermill beater clearances be adjusted or components replaced

- What maintenance procedures help extend hammermill beater service life most effectively