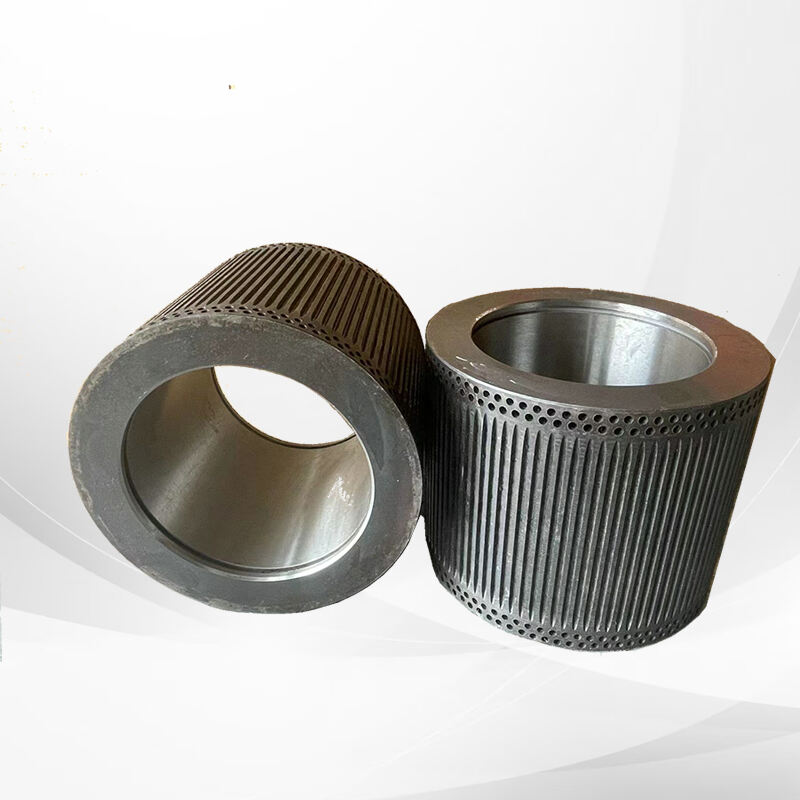

safe hammer mill blade

The safe hammer mill blade represents a significant advancement in industrial grinding technology, combining robust performance with enhanced safety features. This precision-engineered component is designed to efficiently process various materials while maintaining optimal operational safety. The blade features high-grade alloy steel construction, incorporating advanced heat treatment processes that ensure exceptional durability and resistance to wear. Its unique design includes carefully calculated impact angles and specialized edge geometry that maximize grinding efficiency while minimizing the risk of material kickback. The blade's innovative safety features include a specialized mounting system that prevents detachment during operation and built-in stress distribution channels that reduce the likelihood of blade fracture. These blades are particularly well-suited for applications in agricultural processing, waste reduction, biomass preparation, and various industrial grinding operations. The design incorporates strategic placement of wear indicators that allow operators to monitor blade condition without interrupting operations. Each blade undergoes rigorous quality control testing, including balance checking and material composition verification, ensuring consistent performance and safety standards.