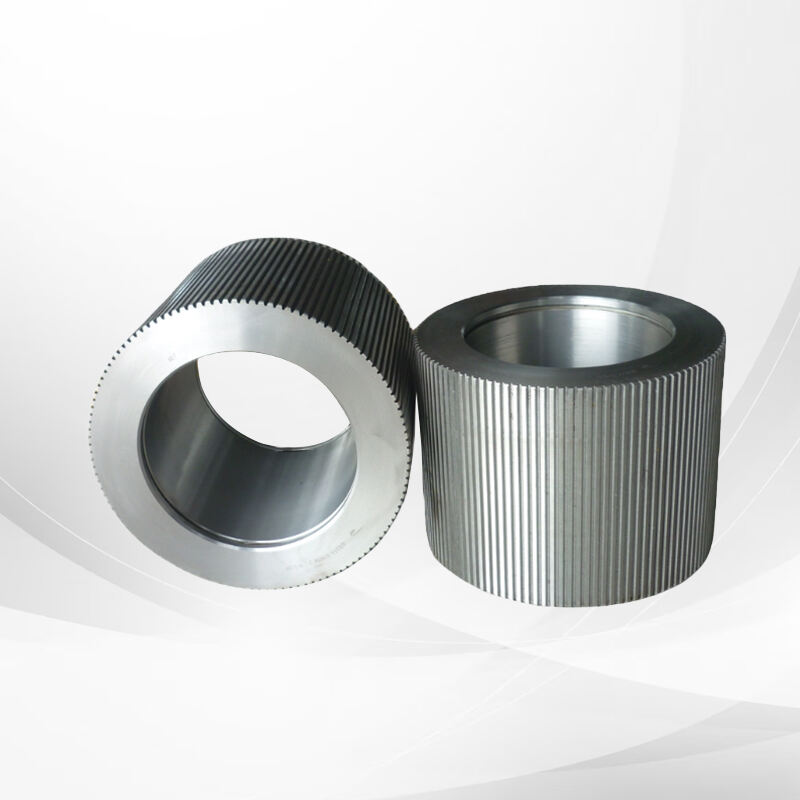

roller shell price

The roller shell price represents a crucial consideration in industrial manufacturing and processing operations, encompassing various factors that influence its cost-effectiveness and performance capabilities. These cylindrical components, essential in equipment like kilns, dryers, and mills, are engineered with precision to ensure optimal operational efficiency. The pricing structure typically reflects the shell's material composition, manufacturing quality, dimensional specifications, and surface treatment requirements. Modern roller shells incorporate advanced metallurgical technologies and precise machining processes, resulting in enhanced durability and consistent performance across diverse applications. The market pricing considers factors such as wear resistance, thermal stability, and load-bearing capacity, which directly impact the shell's longevity and operational reliability. Manufacturers often customize roller shells according to specific industry requirements, affecting the final price point. The investment in quality roller shells proves cost-effective through reduced maintenance needs and extended service life, making it a critical factor in equipment optimization.