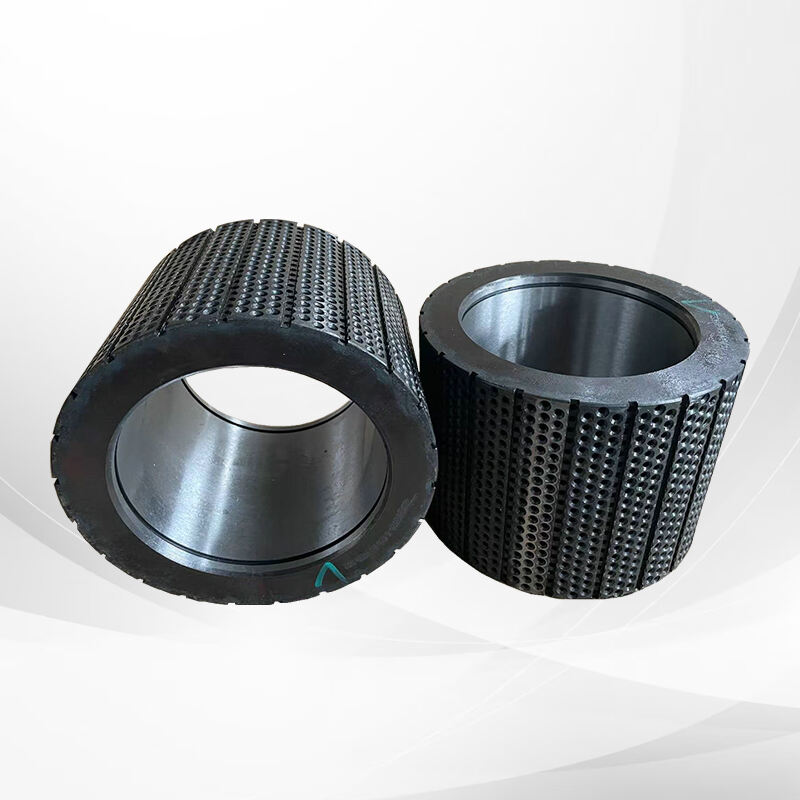

roller shell vendors

Roller shell vendors specialize in providing high-quality cylindrical components essential for various industrial applications. These vendors offer comprehensive solutions for manufacturing processes requiring precision-engineered roller shells, which are crucial elements in industries such as paper production, steel manufacturing, and textile processing. Modern roller shell vendors utilize advanced manufacturing technologies, including computerized numerical control (CNC) machining, precision grinding, and state-of-the-art quality control systems to ensure optimal product performance. Their offerings typically include customizable specifications for diameter, length, material composition, and surface treatments to meet specific application requirements. These vendors also provide expert consultation services to help clients select the most appropriate roller shell configurations for their operational needs, considering factors such as load capacity, speed requirements, and environmental conditions. Additionally, many vendors offer value-added services such as maintenance support, technical documentation, and rapid response for emergency replacements, ensuring minimal downtime for their customers' operations.