shell type needle roller bearings

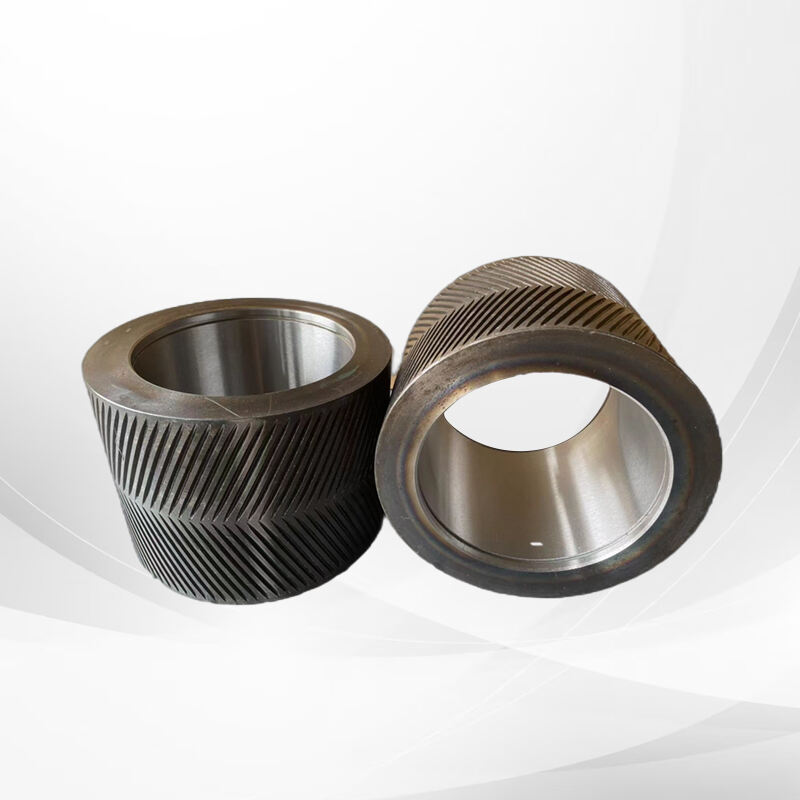

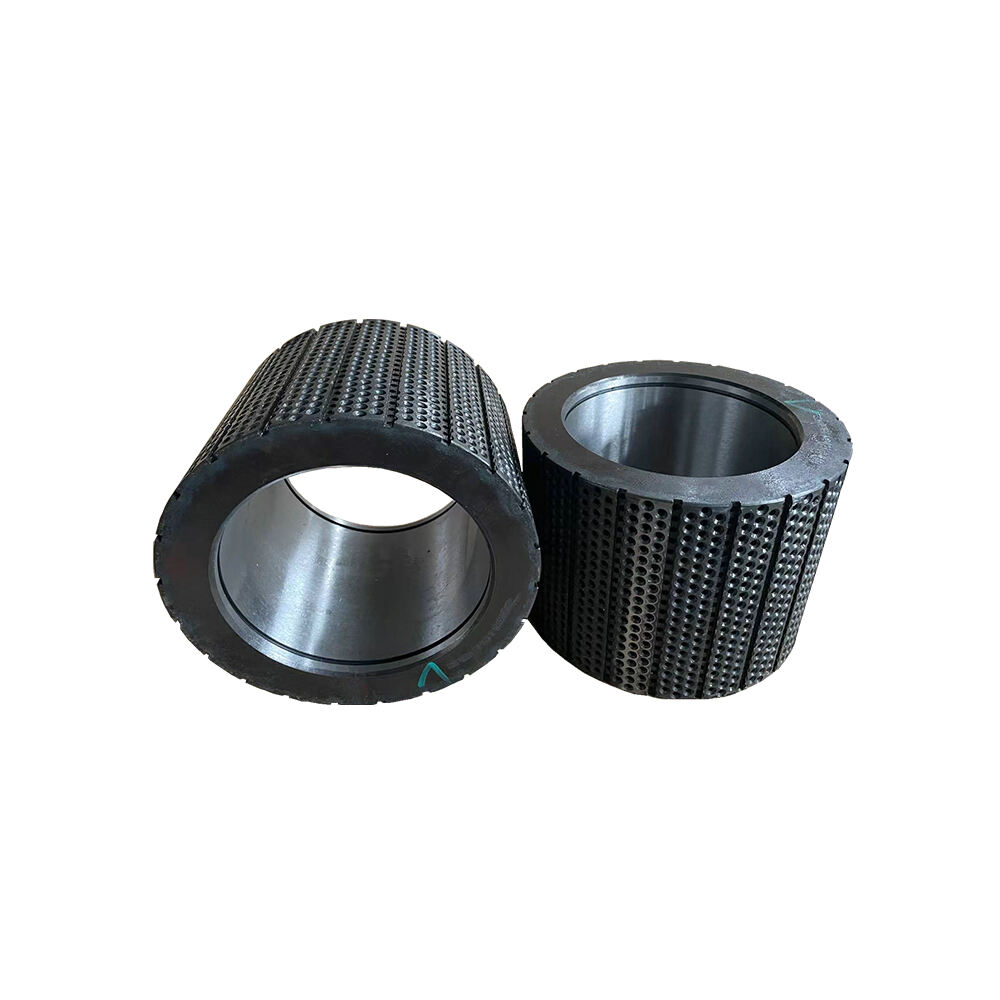

Shell type needle roller bearings represent a sophisticated engineering solution designed to handle radial loads in applications where space is at a premium. These bearings consist of a thin-walled outer ring, also known as the shell, which houses precisely manufactured needle rollers. The shell's design optimizes the bearing's capacity to support high radial loads while maintaining a compact profile, making it ideal for applications where traditional roller bearings would be too large. The bearing's construction allows for high-speed operation while providing exceptional durability and reliability. A key technological feature is the precision-ground raceway surface of the shell, which ensures smooth operation and minimizes friction during rotation. The needle rollers are carefully selected and arranged to maximize load distribution and bearing life. These bearings excel in applications requiring high radial load capacity in limited radial space, such as automotive transmissions, industrial gearboxes, and various machinery components. The shell type design also offers advantages in terms of weight reduction and ease of installation, making them particularly valuable in modern engineering applications where efficiency and space optimization are crucial considerations.