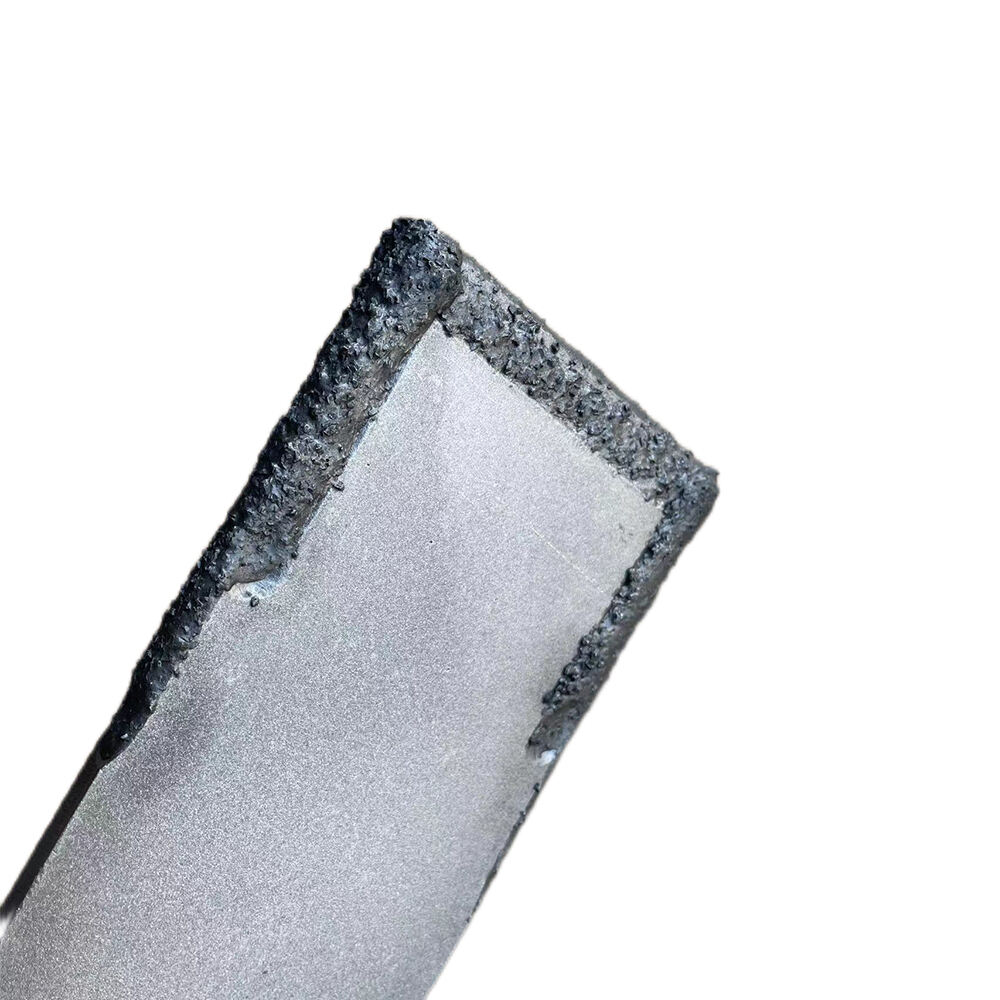

new hammer beater

The new hammer beater represents a significant advancement in material processing technology, combining robust construction with precision engineering. This innovative device features a hardened steel head with optimized impact angles, designed to deliver consistent and efficient beating action across various materials. The unit incorporates a state-of-the-art variable speed control system, allowing operators to adjust beating intensity from 100 to 3000 RPM, making it suitable for both delicate and heavy duty applications. The ergonomic design includes vibration dampening technology and a cushioned grip handle, ensuring operator comfort during extended use periods. Advanced safety features include an emergency stop button, overload protection, and a protective housing that minimizes dust dispersion. The beating chamber is constructed from wear resistant alloy, extending the equipment's operational lifespan while maintaining optimal performance. The digital control panel provides real time monitoring of operational parameters, including speed, temperature, and processing time. This versatile tool serves various industries, from construction material processing to recycling operations, offering unparalleled efficiency in material breakdown and mixing applications.