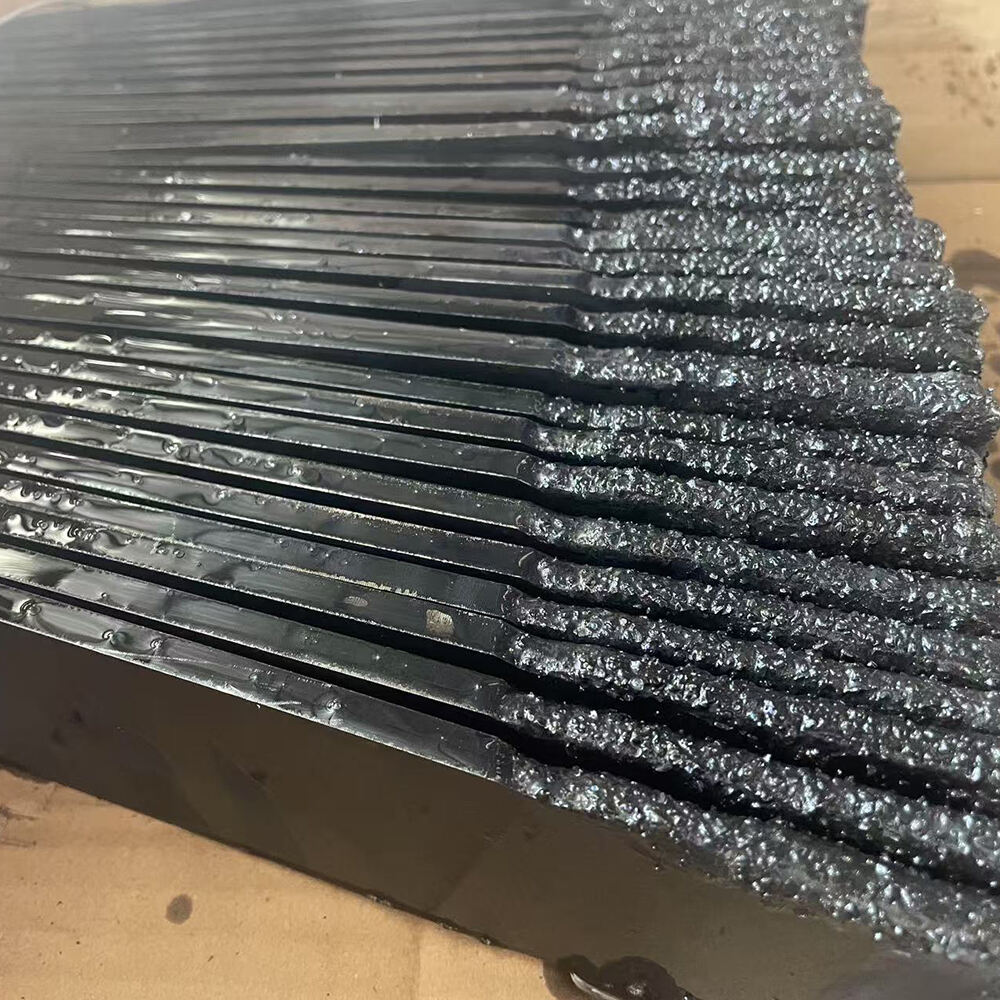

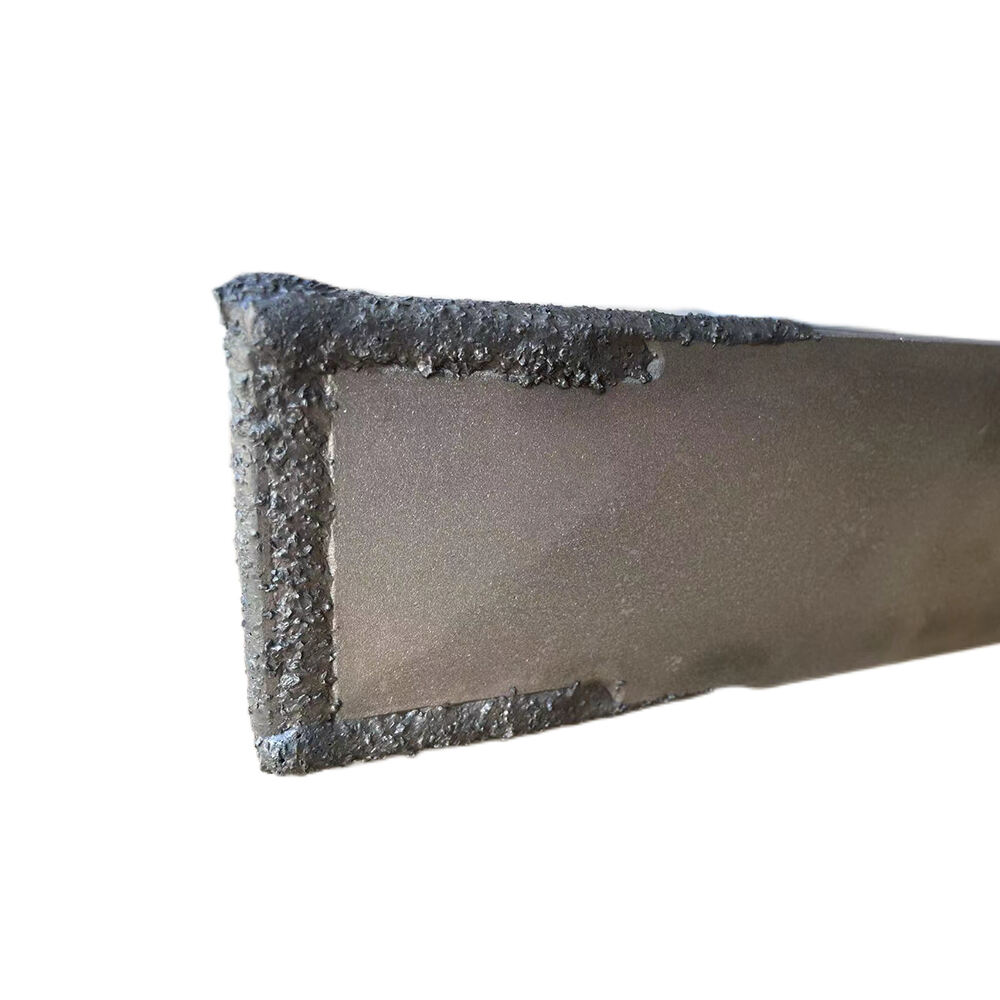

beater hammer

The beater hammer, a versatile industrial tool, represents a significant advancement in material processing and crushing technology. This robust machine combines powerful impact force with precise control mechanisms to effectively break down, crush, or pulverize various materials. At its core, the beater hammer features a rotating shaft equipped with multiple hammer heads that create high-speed impact forces. These hammers are strategically positioned to maximize contact with the material, ensuring optimal crushing efficiency. The machine's design incorporates advanced wear-resistant materials in critical components, particularly in the hammer heads and impact plates, significantly extending its operational lifespan. The beater hammer's versatility is evident in its ability to handle different material types, from minerals and ores to construction waste and agricultural products. Its adjustable crushing chamber allows operators to modify the final product size according to specific requirements. The machine's feed system is engineered to maintain consistent material flow, while its automated control system monitors and adjusts operational parameters in real time. Safety features include emergency shutdown mechanisms and overload protection systems, ensuring safe and reliable operation. The beater hammer's modular construction facilitates easy maintenance and component replacement, minimizing downtime and operational costs.