popular hammer beater

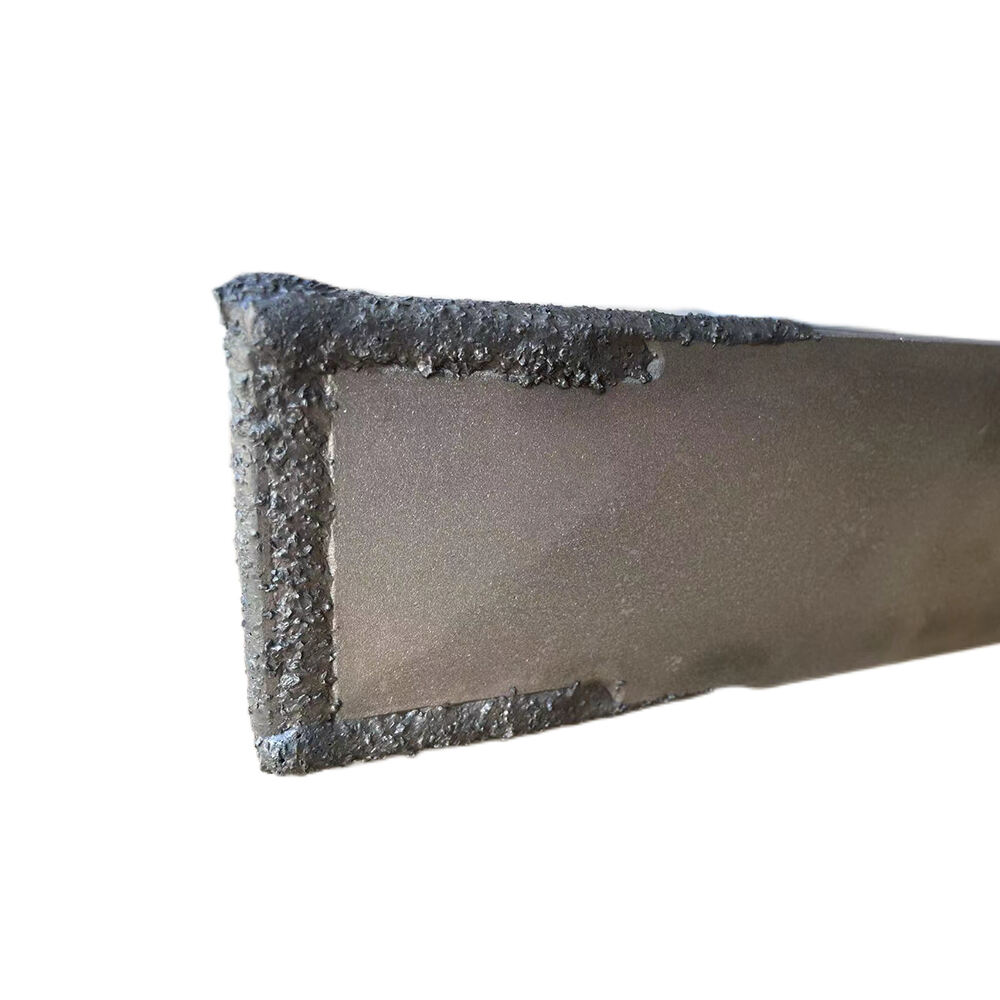

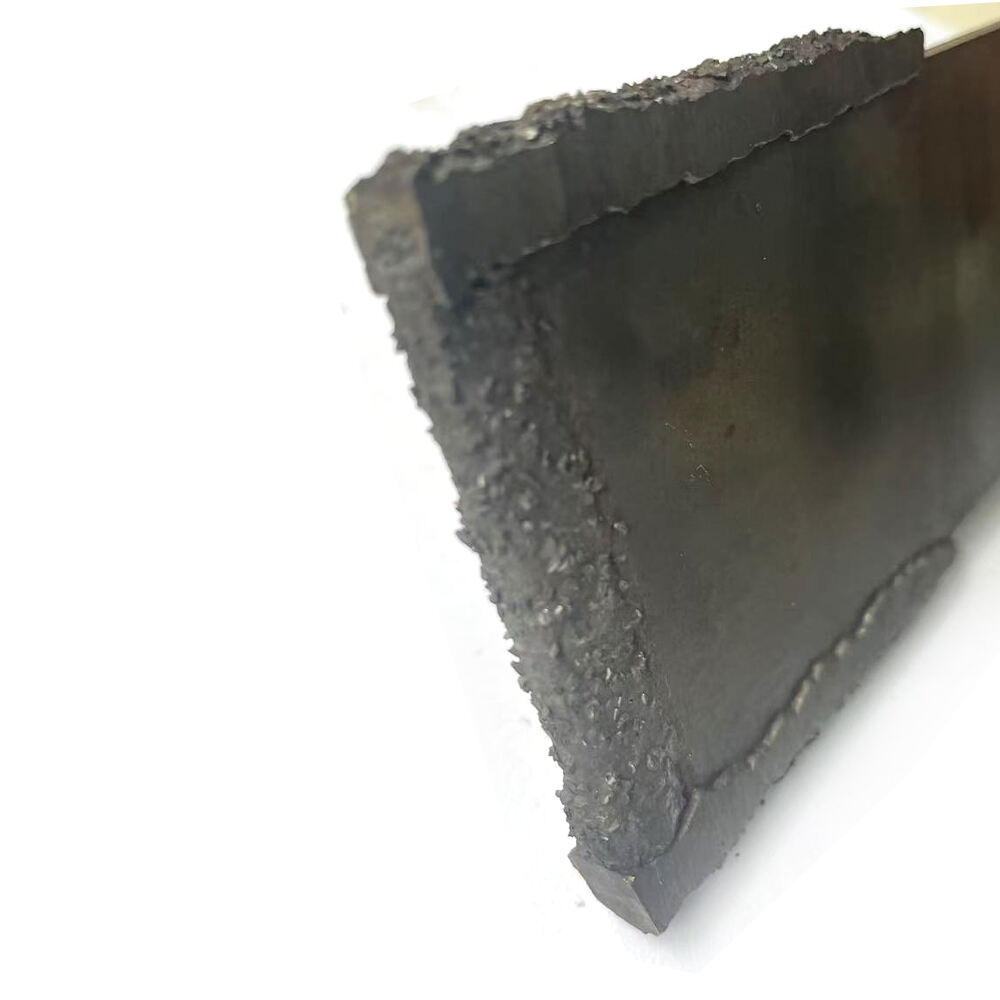

The hammer beater stands as an essential tool in modern industrial and manufacturing processes, representing a significant advancement in material processing technology. This versatile device employs a rotating mechanism equipped with multiple hammers that efficiently break down, crush, and process various materials with remarkable precision. The hammer beater's robust construction features hardened steel hammers mounted on a high-speed rotor, capable of delivering consistent and powerful impacts to achieve optimal material reduction. Its innovative design incorporates advanced safety features, including a sealed housing that prevents dust emission and reduces noise pollution during operation. The machine's adjustable parameters allow operators to control impact force, rotor speed, and feed rate, ensuring optimal processing results across different material types. The system's efficient design minimizes energy consumption while maximizing throughput, making it an economical choice for various industries. Applications range from agricultural processing and waste reduction to mineral crushing and recycling operations, demonstrating its exceptional versatility. The hammer beater's intelligent control system enables precise monitoring of operating conditions, ensuring consistent performance and reducing maintenance requirements. This combination of durability, efficiency, and versatility has established the hammer beater as a cornerstone of modern material processing operations.