advanced hammer beater

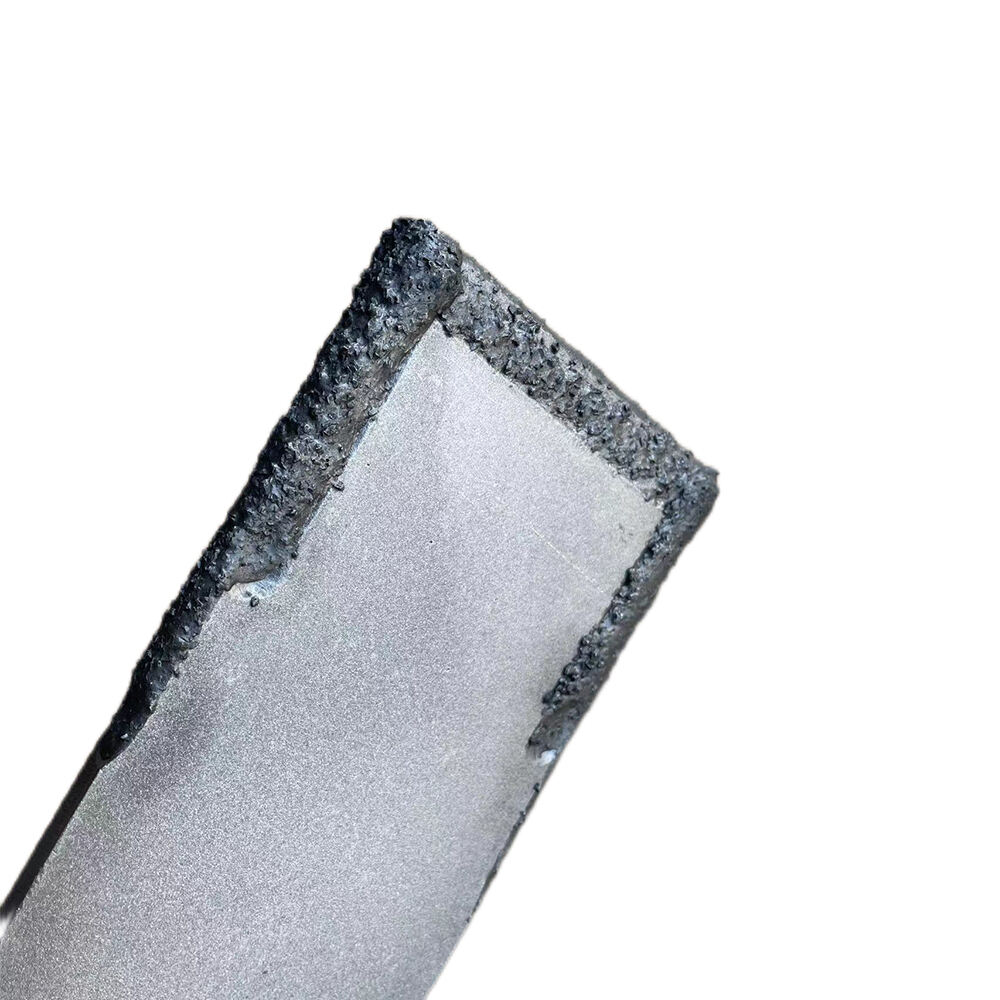

The advanced hammer beater represents a significant leap forward in material processing technology, combining robust construction with precision engineering to deliver superior performance. This innovative tool features a hardened steel head with optimized striking surfaces, engineered to provide maximum impact force while maintaining controlled operation. The ergonomically designed handle incorporates vibration-dampening technology, reducing operator fatigue during extended use. Built with industrial-grade materials, the advanced hammer beater can process various materials, from agricultural products to industrial compounds, with exceptional efficiency. Its automated control system allows for precise adjustment of beating frequency and intensity, ensuring consistent results across different applications. The machine's sophisticated monitoring system provides real-time feedback on performance metrics, enabling operators to maintain optimal processing conditions. Safety features include emergency shutdown mechanisms and protective enclosures that comply with international safety standards. The advanced hammer beater's modular design facilitates easy maintenance and component replacement, minimizing downtime and extending operational lifespan. Its versatile configuration options accommodate different material types and processing requirements, making it suitable for various industrial applications.