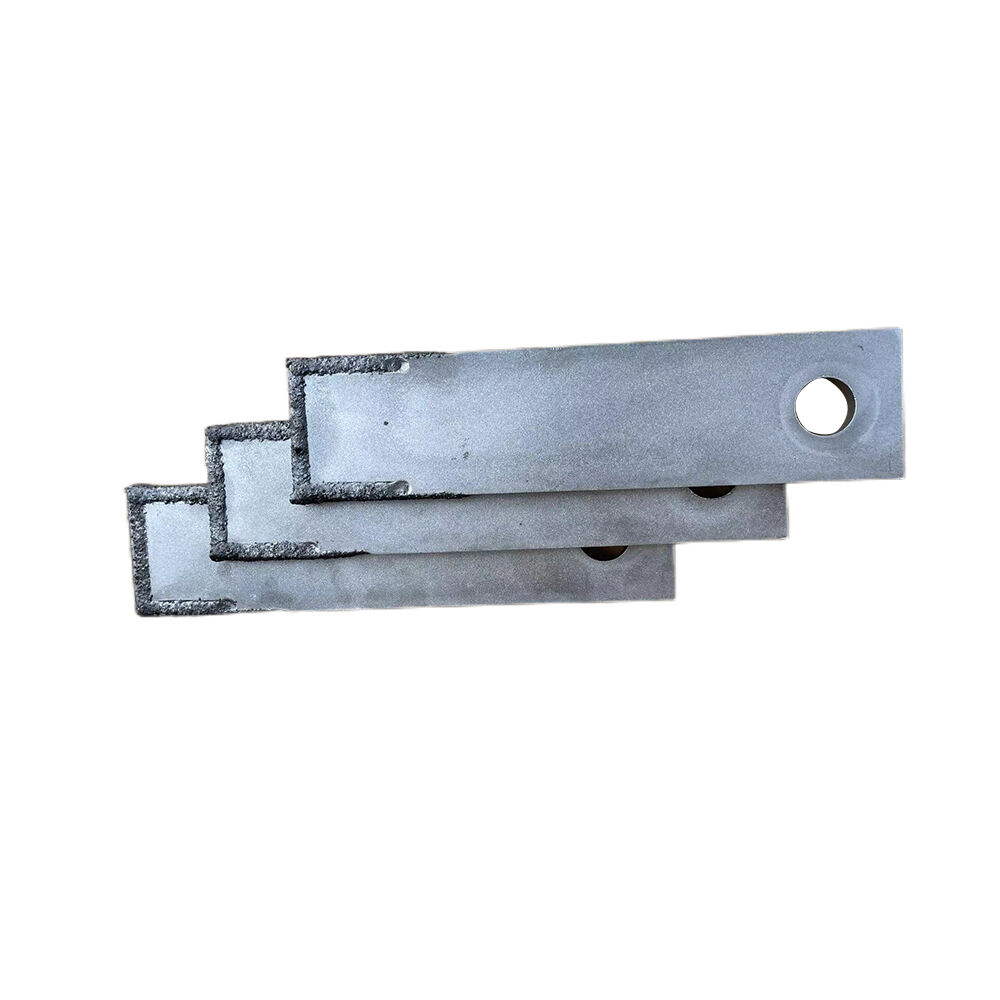

hammer blade manufacturer

A hammer blade manufacturer represents a crucial player in the industrial cutting and processing sector, specializing in the production of high-performance blades designed for various crushing and grinding applications. These manufacturers utilize advanced metallurgical processes and precision engineering to create durable, efficient hammer blades that deliver consistent performance in demanding industrial environments. The manufacturing process incorporates state-of-the-art CNC machining, heat treatment technologies, and rigorous quality control measures to ensure each blade meets exact specifications. These facilities typically offer customization options to accommodate specific operational requirements, whether for mining, recycling, agricultural, or waste management applications. The production line employs sophisticated material selection processes, focusing on high-grade steel alloys that provide optimal wear resistance and longevity. Modern hammer blade manufacturers also implement automated production systems that ensure precise dimensional accuracy and consistent quality across large production runs. They typically maintain extensive research and development departments dedicated to improving blade designs, exploring new materials, and developing innovative solutions for emerging industry challenges.