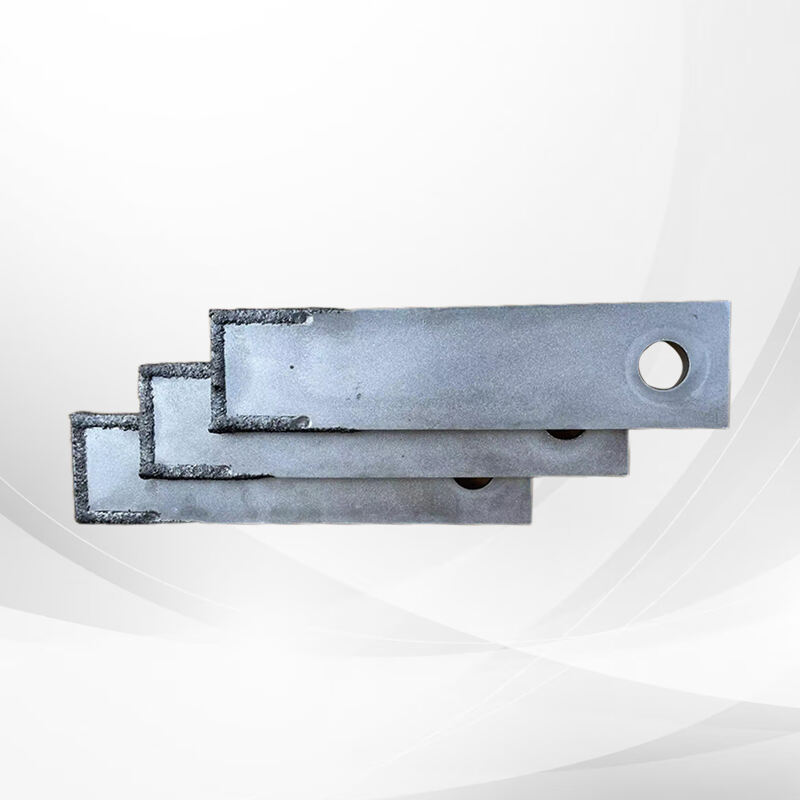

hammer blade types

Hammer blade types represent a crucial component in industrial grinding and processing equipment, offering diverse configurations for various material reduction applications. These specialized blades combine durability with precision engineering, featuring hardened steel construction and specialized geometric designs that optimize cutting efficiency. The primary types include straight hammer blades, reversible hammer blades, and swing hammer blades, each engineered for specific applications. Straight hammer blades excel in consistent particle size reduction, while reversible designs offer extended service life through multiple cutting edges. Swing hammer blades provide enhanced flexibility in processing various materials. Modern hammer blade designs incorporate advanced metallurgical compositions that resist wear and maintain sharp cutting edges under demanding conditions. The blade geometry is carefully calculated to maximize impact force while minimizing energy consumption, resulting in efficient material processing. These blades are essential in industries ranging from agricultural processing and recycling to mining and biomass reduction, where they handle materials from wood and crop residues to minerals and waste products. The technology behind hammer blade types continues to evolve, with manufacturers introducing innovations in blade profiles, mounting systems, and material compositions to enhance performance and longevity.