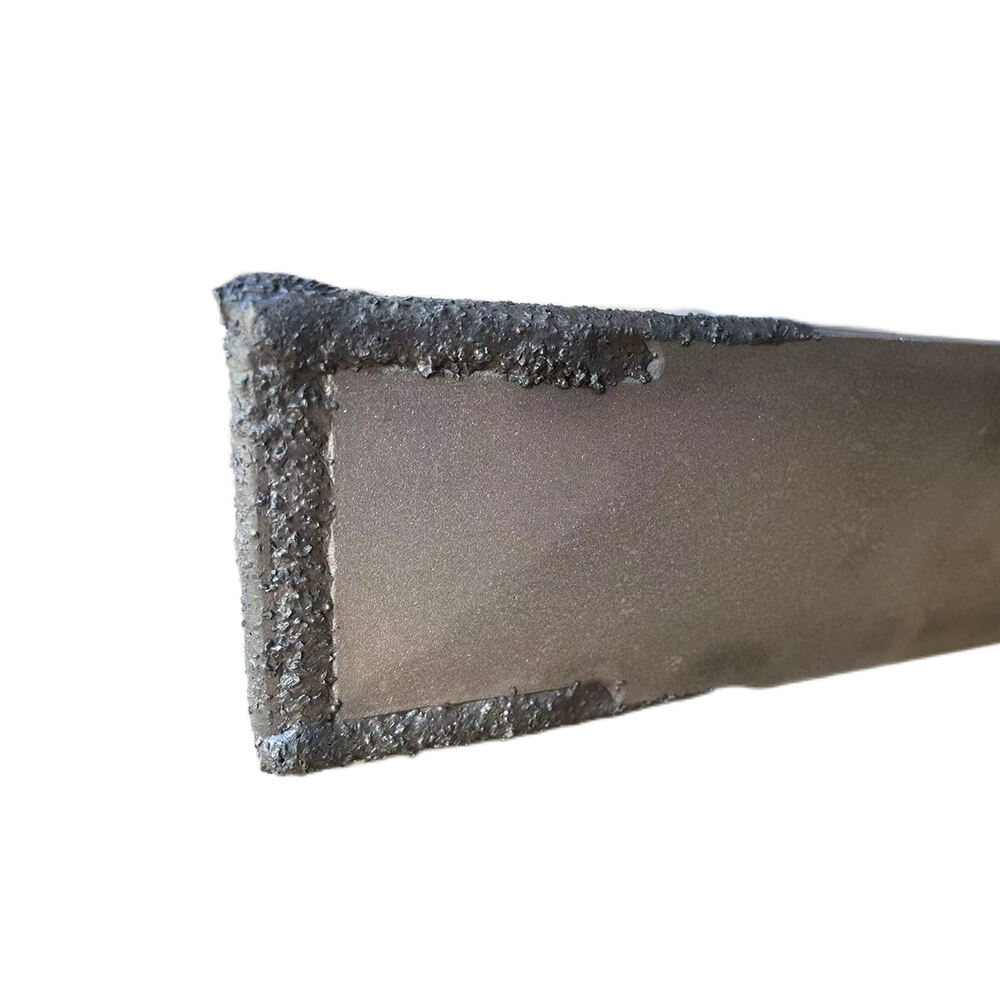

customized hammer blade

The customized hammer blade represents a breakthrough in industrial cutting technology, combining precision engineering with adaptable design to meet diverse manufacturing needs. This innovative tool features a high-grade steel construction with specialized heat treatment processes, ensuring exceptional durability and consistent performance across multiple applications. The blade's unique geometry incorporates advanced serration patterns that enhance cutting efficiency while minimizing material waste. Its customizable design allows for precise adjustments to match specific cutting requirements, whether for metalworking, woodworking, or composite materials processing. The hammer blade's innovative mounting system enables quick installation and replacement, reducing downtime and increasing operational efficiency. Advanced coating technologies provide superior wear resistance and extended service life, while the ergonomic design ensures optimal control and reduced operator fatigue. The blade's cutting edge maintains its sharpness through extended use, featuring self-sharpening capabilities that contribute to lower maintenance requirements and increased productivity. Modern manufacturing techniques ensure consistent quality across each unit, with rigorous testing protocols guaranteeing performance standards.