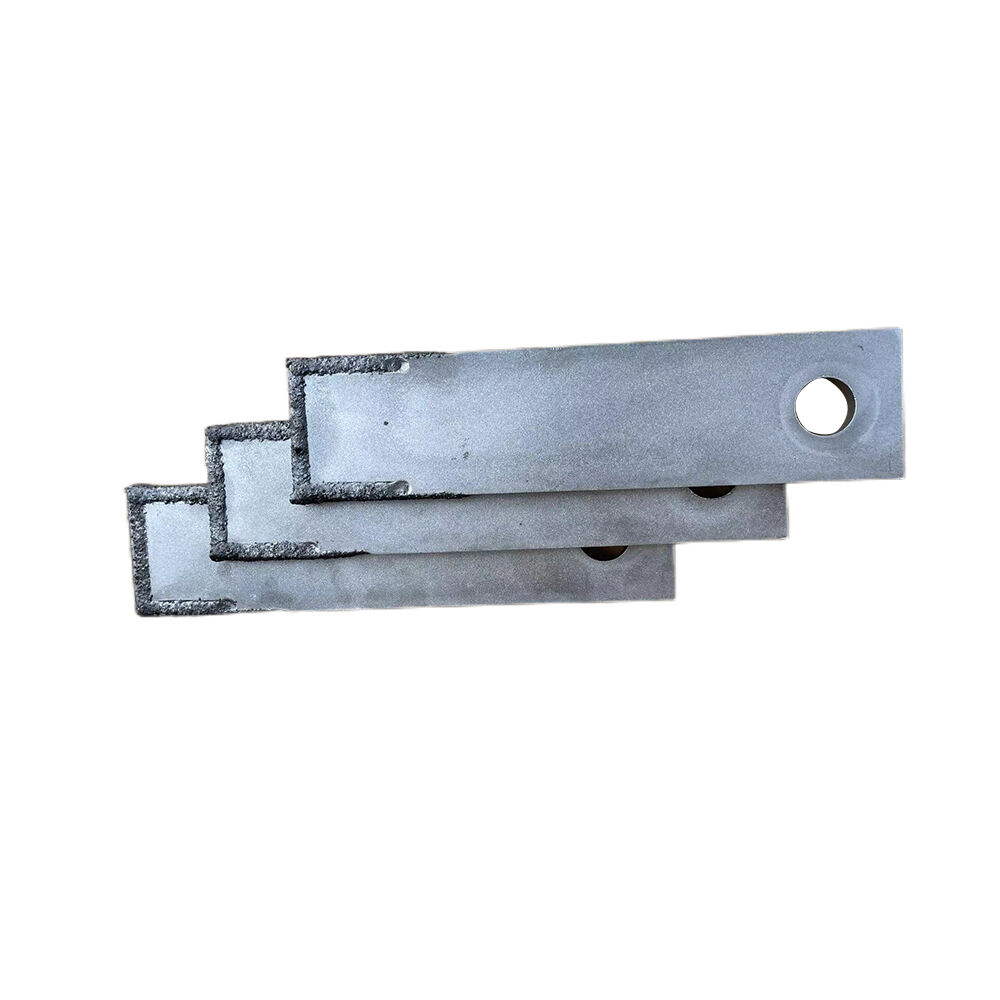

hammer blade for sale

The hammer blade for sale represents a cutting-edge solution in industrial cutting technology, combining durability with precision engineering. This versatile tool features high-grade steel construction with specialized heat treatment, ensuring exceptional hardness and wear resistance. The unique design incorporates an innovative hammer-style cutting edge that delivers both impact force and slicing capability, making it ideal for various industrial applications. The blade's geometry has been carefully engineered to maintain sharpness while providing optimal cutting angles for different materials. Enhanced with advanced coating technology, these blades resist corrosion and maintain their edge longer than conventional options. The ergonomic design ensures proper weight distribution, reducing operator fatigue during extended use. Available in multiple sizes to accommodate different machinery specifications, each blade undergoes rigorous quality control testing to ensure consistent performance. The hammer blade's reinforced core structure prevents warping under high-stress conditions, while its precision-ground edges guarantee clean, efficient cuts every time. These blades are compatible with most standard industrial cutting equipment and feature quick-change mounting systems for minimal downtime during replacements.