animal pellet machine

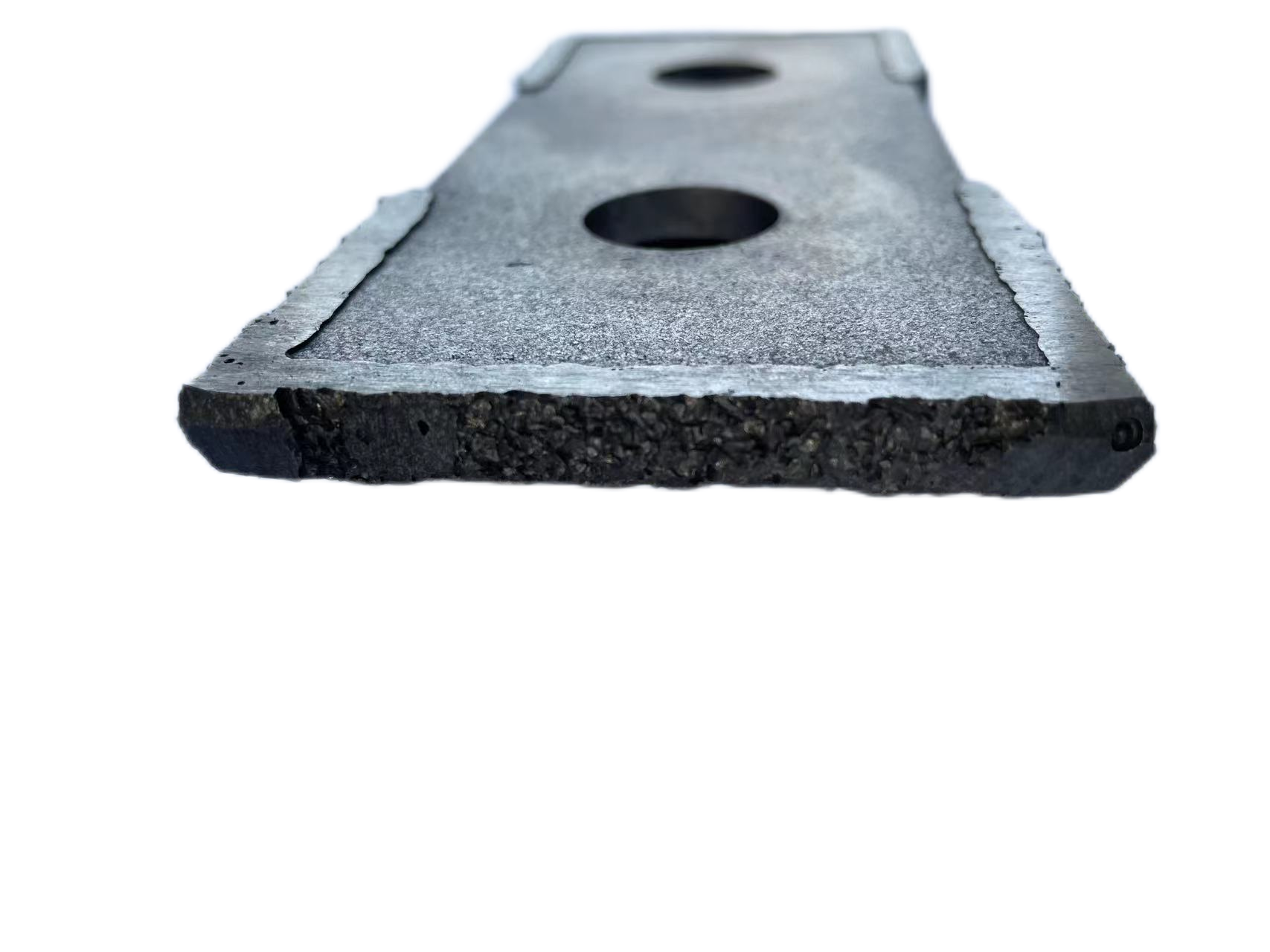

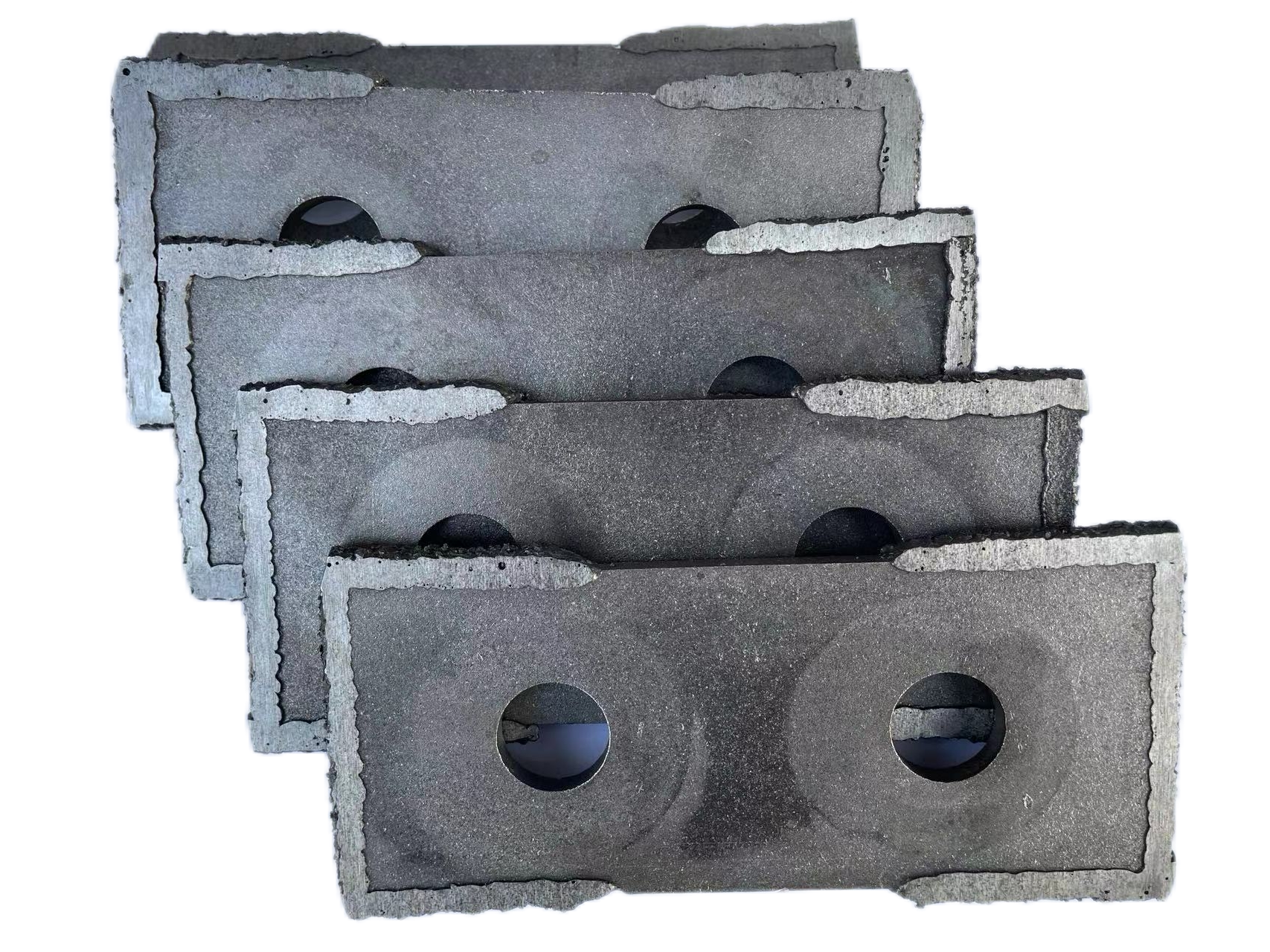

The animal pellet machine is a sophisticated piece of equipment designed to transform raw feed materials into uniform, easily digestible pellets for livestock and pets. This versatile machine efficiently processes various ingredients, including grains, proteins, vitamins, and minerals, into compressed feed pellets that optimize animal nutrition and reduce waste. The machine operates through a systematic process that begins with material mixing, followed by conditioning with steam or water to achieve optimal moisture content and temperature. The mixture is then forced through a die plate with specifically sized holes, creating cylindrical pellets that are cut to desired lengths. Advanced models feature precise temperature control systems, adjustable die configurations, and automated monitoring capabilities to ensure consistent product quality. The technology incorporates energy-efficient motors and durable wear-resistant components, enabling continuous operation in demanding production environments. These machines are available in various capacities, from small-scale operations processing 50 kg per hour to industrial units handling several tons hourly. The pellet machine's versatility extends to producing feed for different animal species, including cattle, poultry, fish, and pets, with adjustable parameters to meet specific nutritional requirements and pellet specifications.