ağac qurğan mill qiyməti

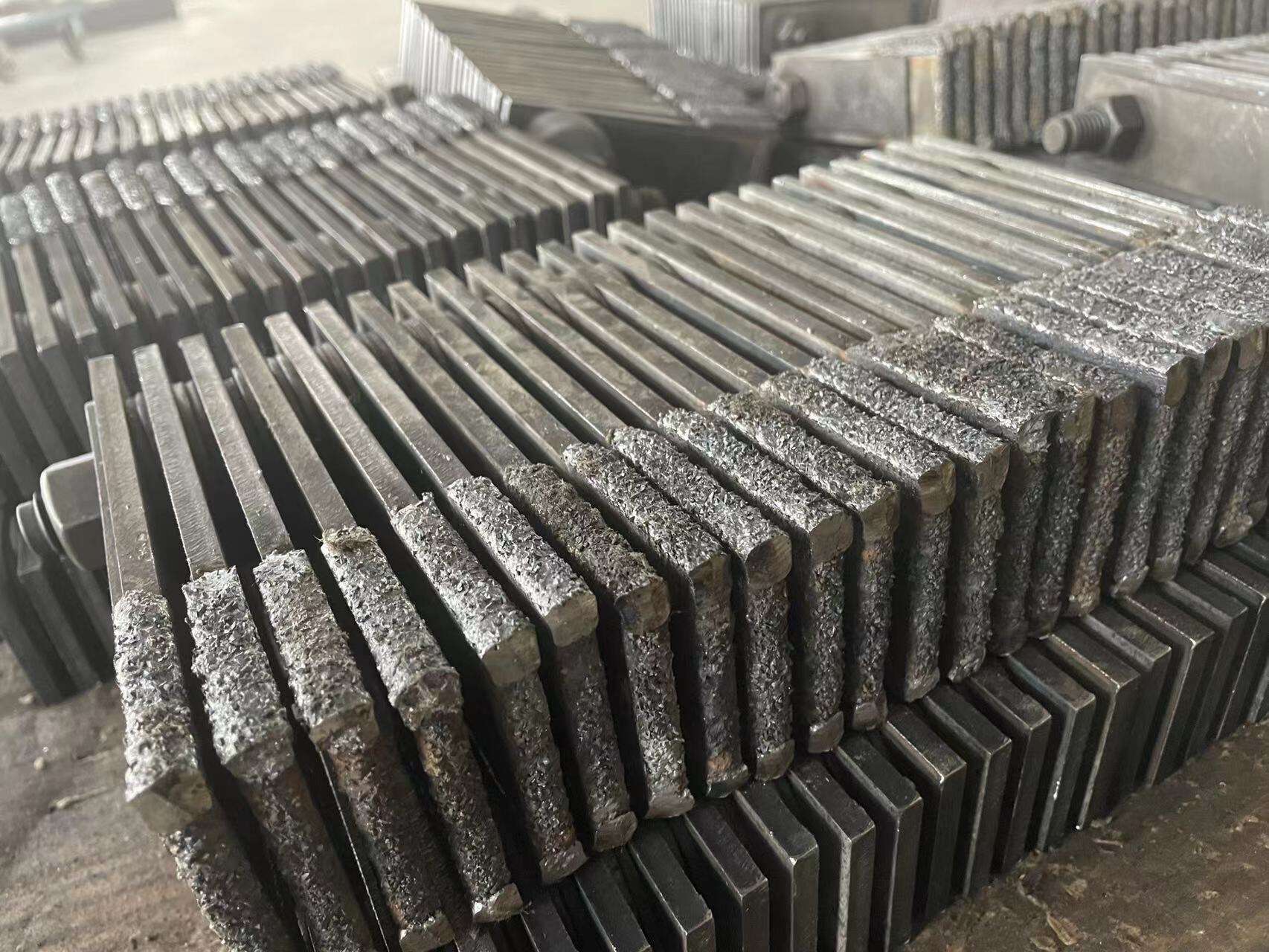

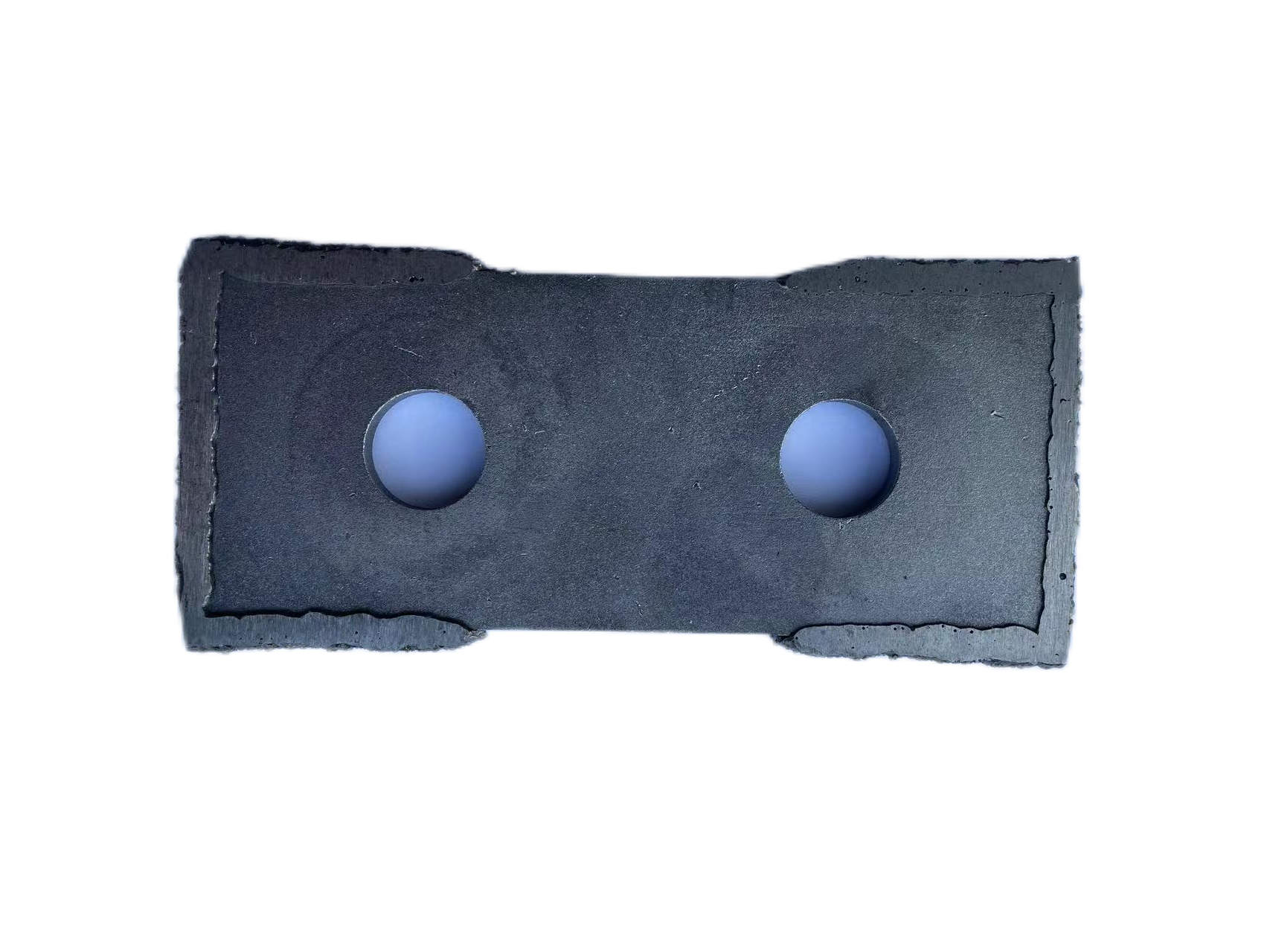

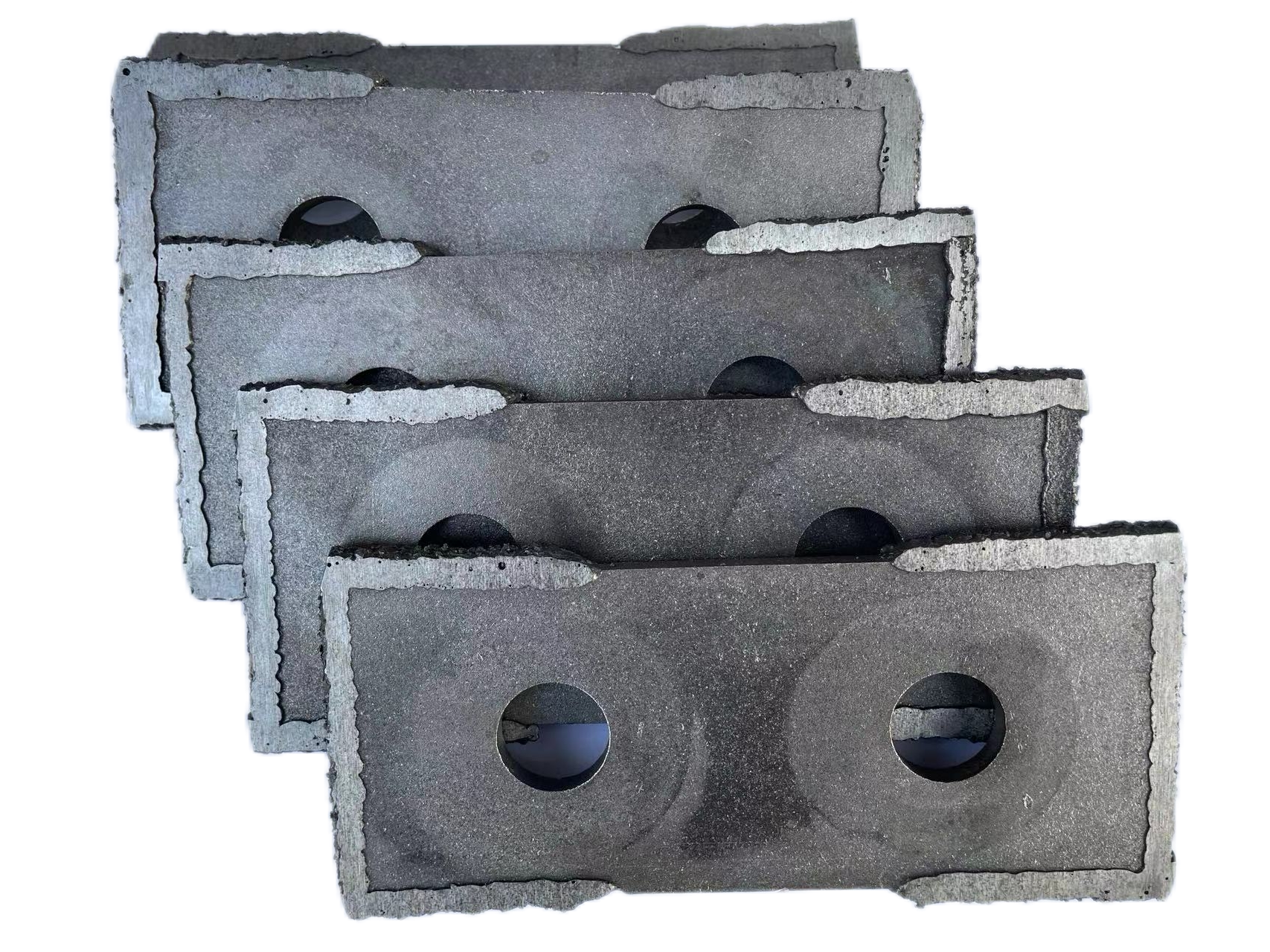

Əhram qayğı məhsulunun qiyməti, biomas əməliyyatı təchizatına investisiya etmək istəyən iş mənzilləri və şəxslər üçün əsas bir nəzərdən keçid təşkil edir. Bu maşınlar, $2,000-dən $50,000-ə qədər fərqli qiymət diapazonlarında mövcud olup, ham biomas materiallarını yüksək sıxlıqda əhram qayğılarına çevirməyə imkan verən müxtəlif həllər təqdim edir. Qiymət fərqliliyi əsasən produksiya kapasiti (50 kg/saatdan 5 ton/saata qədər), motor gücü xüsusiyyətləri və ümumi inkişaf keyfiyyətinə görə dəyişir. Mütəxəssis əhram qayğı maşınları avtomatik temperatur idarəetmə sistemləri, səlislik ilə vəziyyət və rullar konfigurasiyası və smart izləmə imkanları kimi yenilikçi funksiyaları özündə birləşdirir. Təchizatın dizaynı optimal sıxışdırma nisbətləri və isti paylanma üzərində odaklaşır və giriş materialından asılı olmayaraq stabilləşmiş əhram keyfiyyəti təmin edir. Bu maşınlar tipik olaraq, yemək sistemi, hazırlama otağı, əhramlaşdırma otağı və soğutma sistemi kimi əsas komponentləri əhatə edir ki, bu da son qiymətə təsir edir. İnvestisiya nəzərdən keçidində, təhlükəsizlik mekanizmləri, texniki idarəetmə əlverişliliyi və enerji effektivliyi reytinqləri kimi əlavə xüsusiyyətlər hesab edilməlidir, çünki bu, ümumi iş kostları və investisiya üzərində qayıdlarını əhəmiyyətli şəkildə təsirləyə bilər.