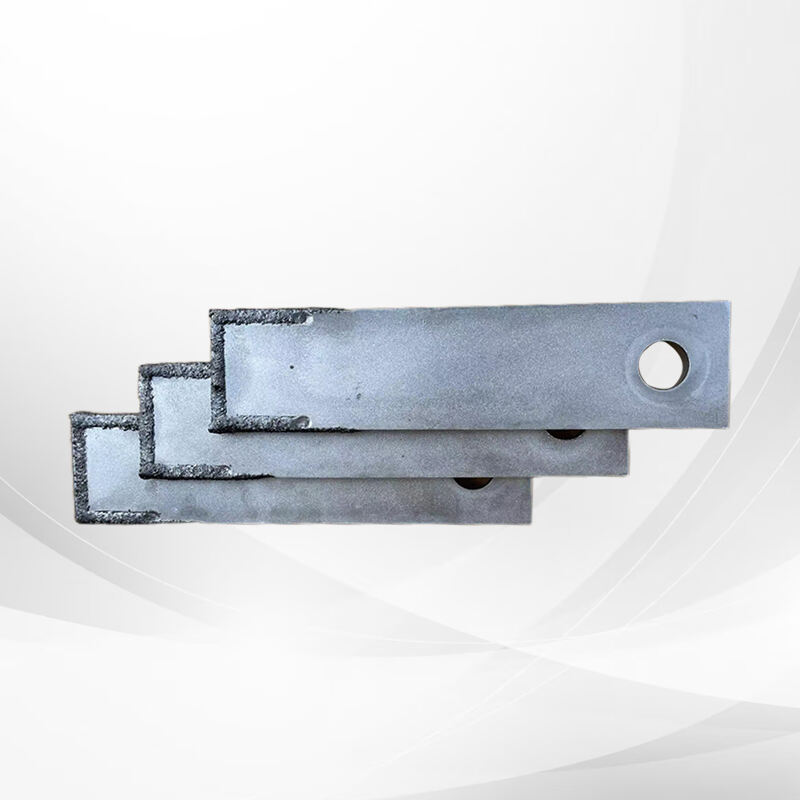

the hammer beater

A hammer beater is a specialized mechanical component designed to efficiently process various materials through impact-based operations. This versatile tool consists of a rotating shaft equipped with multiple hammers that swing freely, delivering powerful striking forces to break down, crush, or pulverize materials. The device employs advanced engineering principles to maintain optimal striking force while minimizing energy consumption. The hammers are strategically positioned to ensure uniform material processing and consistent output quality. The system incorporates sophisticated safety features, including protective housing and emergency shut-off mechanisms, ensuring operator safety during operation. Modern hammer beaters often feature adjustable rotation speeds and interchangeable hammers to accommodate different material types and desired output sizes. The technology behind hammer beaters has evolved to include precision-balanced components, reducing vibration and wear while extending operational lifespan. These machines find extensive applications in industries such as mining, recycling, agricultural processing, and waste management, where efficient material reduction is crucial. The design typically includes specialized wear-resistant materials in high-impact areas, ensuring durability and reduced maintenance requirements.