stable hammer blade

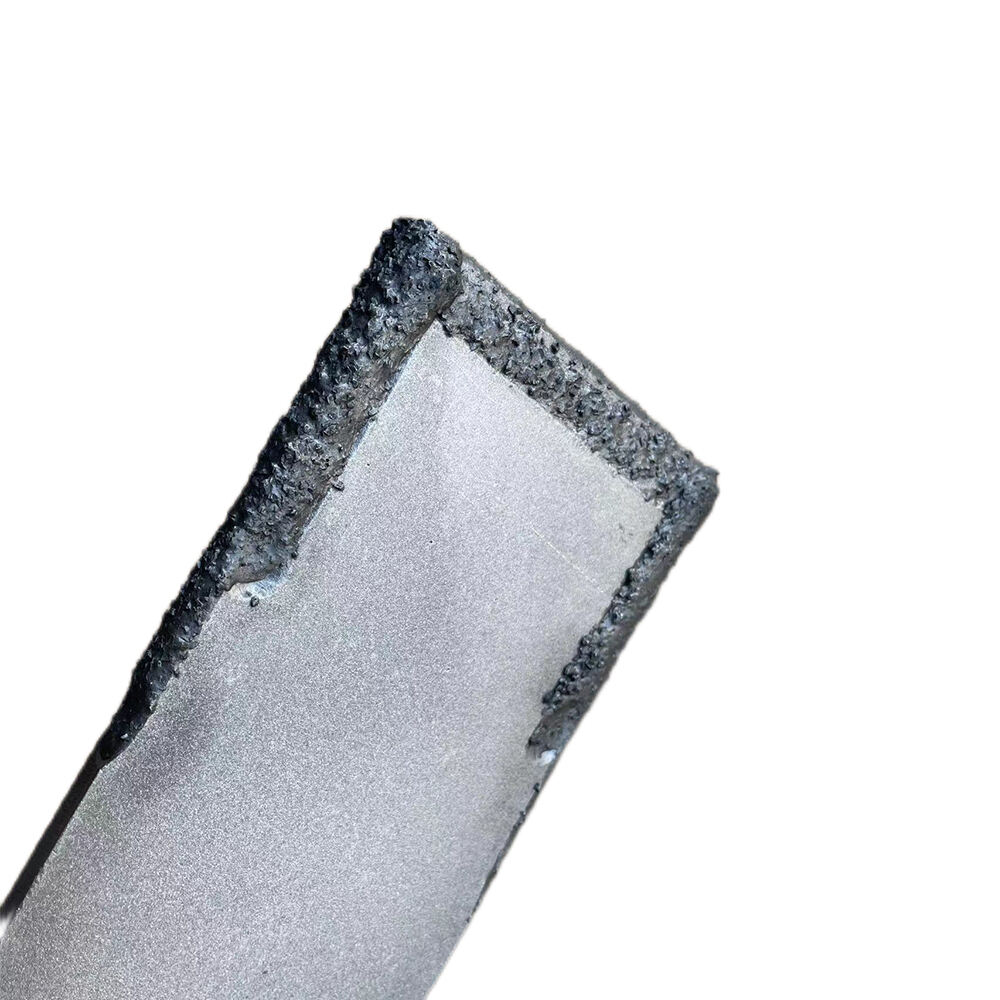

The stable hammer blade represents a significant advancement in industrial cutting technology, combining durability with precision engineering. This robust cutting implement features a high-carbon steel construction with specialized heat treatment, ensuring exceptional wear resistance and maintaining its sharp edge through extended use. The blade's unique design incorporates a weighted hammer mechanism that provides consistent force distribution during operation, resulting in clean, precise cuts across various materials. The innovative stability control system minimizes vibration and maintains balance during high-speed operations, making it ideal for both automated and manual cutting processes. The blade's geometry has been optimized through computer-aided design to achieve maximum cutting efficiency while reducing material waste. Its corrosion-resistant coating extends the tool's lifespan and maintains performance in challenging environmental conditions. The stable hammer blade excels in both continuous production environments and intermittent cutting applications, making it a versatile choice for manufacturing facilities, fabrication shops, and industrial processing plants.