second hand pellet machines for sale

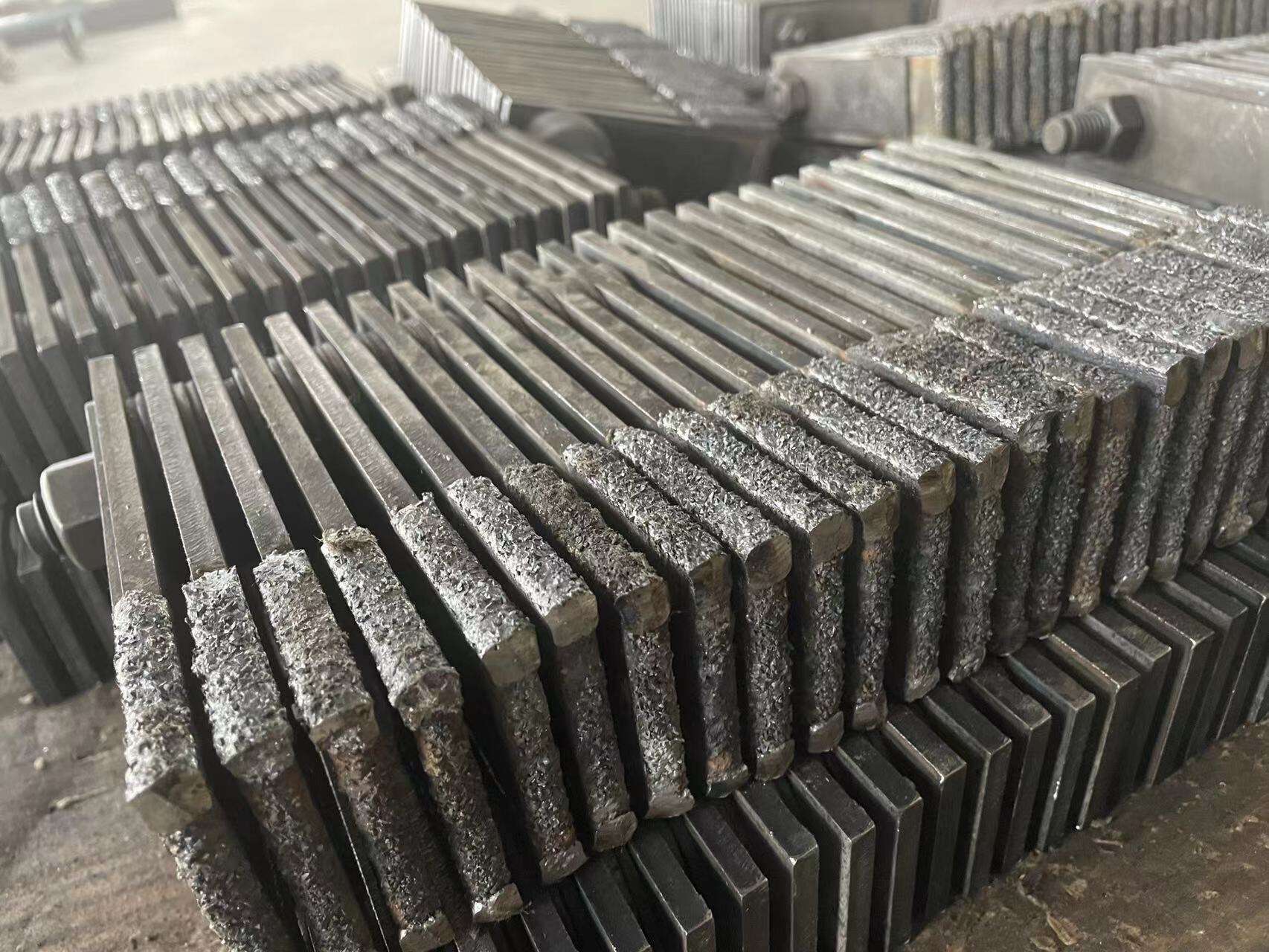

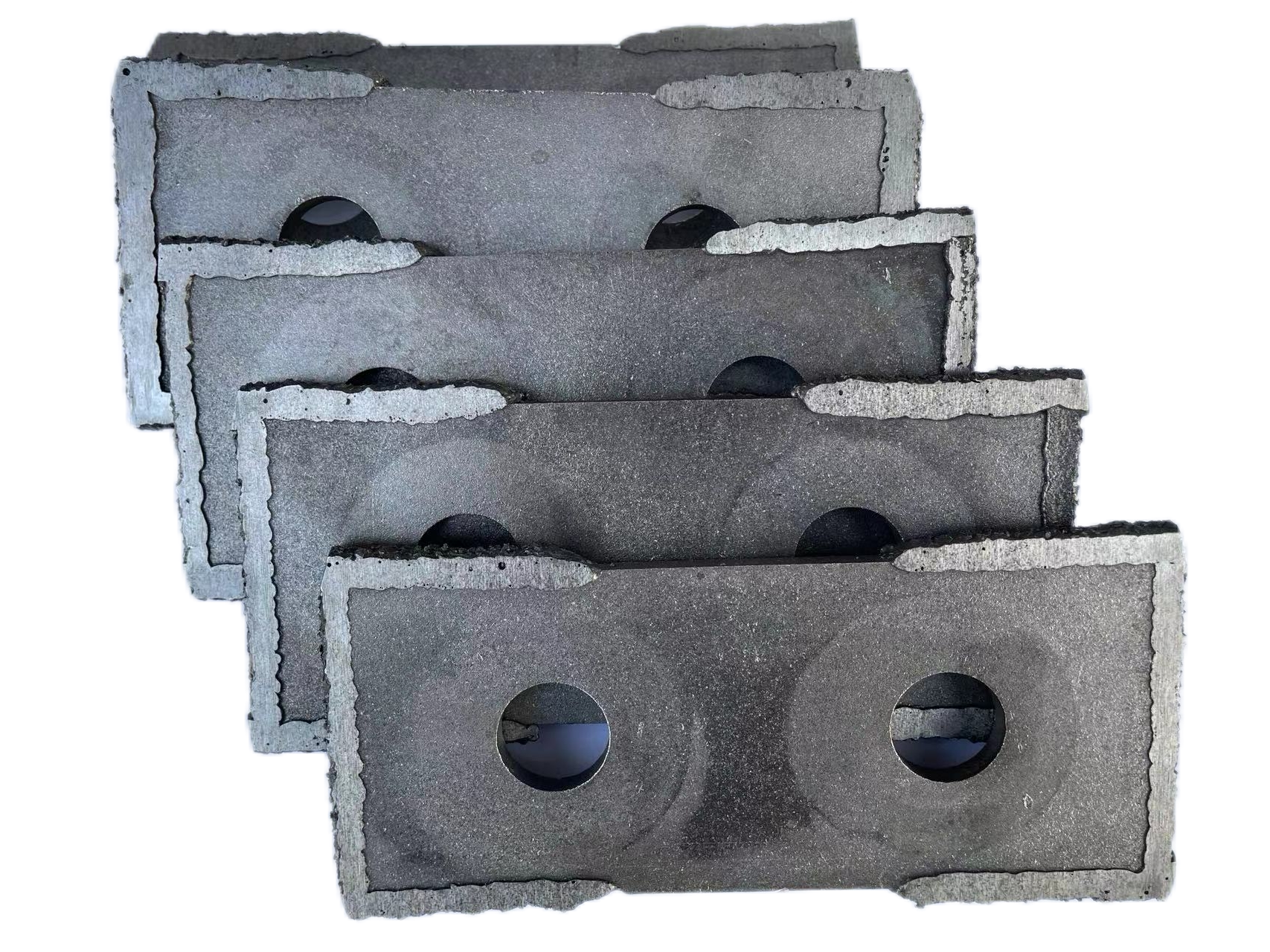

Second hand pellet machines for sale represent a cost-effective solution for businesses entering the biomass processing industry. These refurbished units maintain high performance standards while offering significant cost savings compared to new equipment. These machines efficiently convert various raw materials, including wood waste, agricultural residues, and sawdust, into uniform, dense pellets suitable for multiple applications. The machines typically feature robust construction with wear-resistant dies and rollers, ensuring reliable operation even after previous use. Most second hand units undergo thorough inspection and maintenance processes, including replacement of critical components when necessary, to guarantee optimal performance. They come equipped with essential features such as automatic lubrication systems, safety controls, and adjustable cutting mechanisms. The pellet production capacity ranges from 100kg to several tons per hour, depending on the model and size. These machines incorporate advanced pelletizing technology, including precise temperature and pressure control systems, ensuring consistent pellet quality. They also feature efficient cooling systems to maintain optimal operating temperatures and extend component life. Many units include digital control panels for easy operation and monitoring of key parameters like temperature, pressure, and production rate.