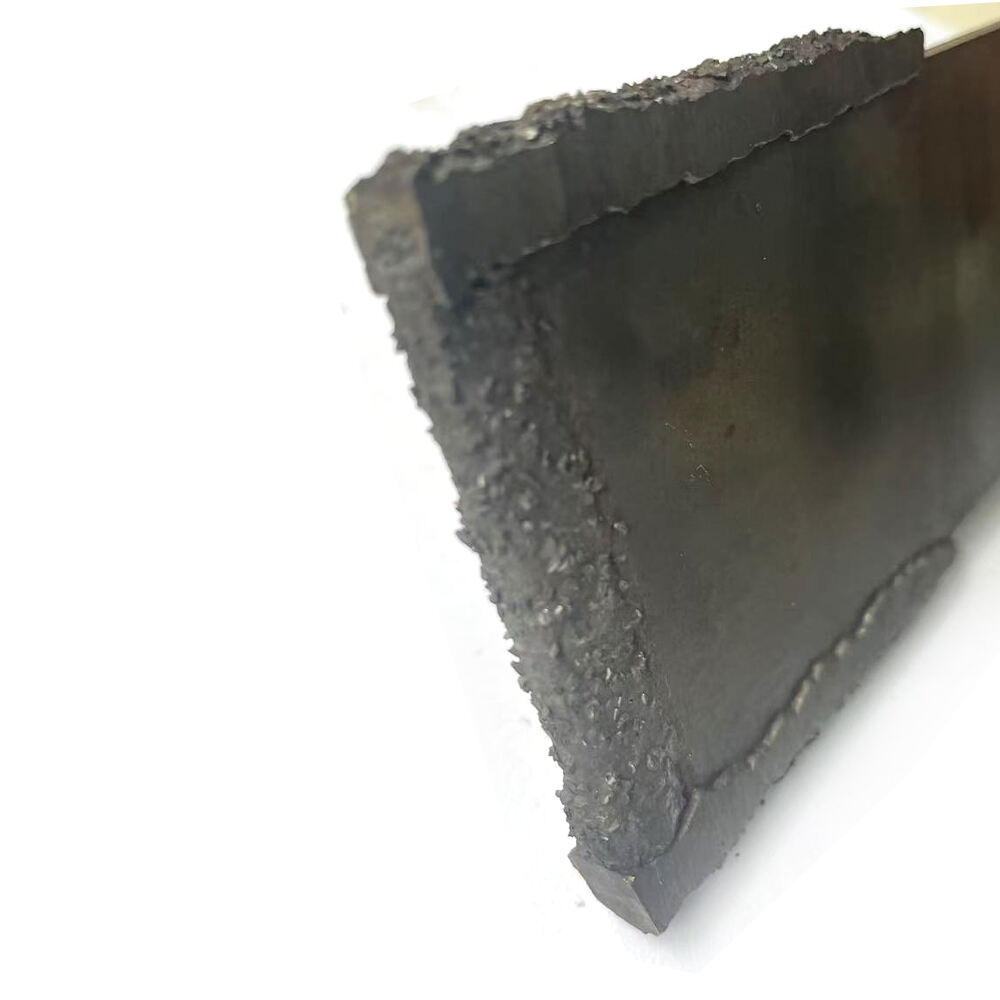

newest hammer beater

The latest hammer beater represents a significant advancement in material processing technology, combining robust construction with intelligent design features. This innovative device delivers exceptional performance through its hardened steel head and precision-engineered striking surface. The beater operates at variable speeds ranging from 1,000 to 3,000 RPM, allowing for optimal processing of different materials. Its advanced electronic control system enables precise adjustment of impact force and frequency, ensuring consistent results across various applications. The device features an ergonomic design with vibration-dampening technology, significantly reducing operator fatigue during extended use. With its industrial-grade motor and reinforced bearing system, the hammer beater maintains stable operation even under heavy workloads. The unit includes an integrated cooling system that prevents overheating during continuous operation, while its dust-sealed housing protects internal components from contamination. The smart monitoring system provides real-time feedback on operational parameters, allowing users to optimize performance and prevent potential issues. This hammer beater is particularly well-suited for applications in mining, construction, and material processing industries, offering versatility in handling various materials from minerals to construction waste.