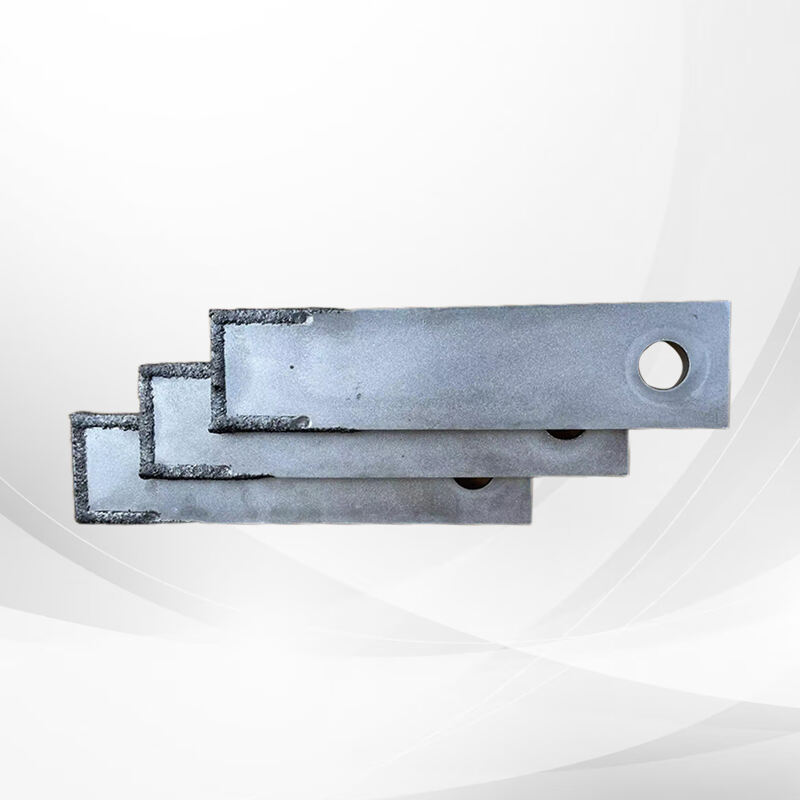

new hammer blade

The new hammer blade represents a significant advancement in cutting technology, combining the robust power of a hammer mechanism with precision blade engineering. This innovative tool features a high-carbon steel construction with a specialized coating that enhances durability and reduces friction during operation. The blade's unique design incorporates serrated edges alongside a smooth cutting surface, enabling versatile performance across different materials. Its ergonomic handle design integrates vibration-dampening technology, ensuring comfortable extended use while maintaining precise control. The hammer blade's advanced pivot system allows for quick blade deployment and secure locking, essential for safety during intensive cutting tasks. With adjustable strike force settings, users can fine-tune the tool's impact power to match specific material requirements. The integration of modern materials science has resulted in a lightweight yet robust tool that maintains structural integrity even under demanding conditions. This versatility makes it ideal for construction, woodworking, metalworking, and various industrial applications. The hammer blade's innovative design also includes a quick-release mechanism for easy maintenance and blade replacement, minimizing downtime in professional settings.