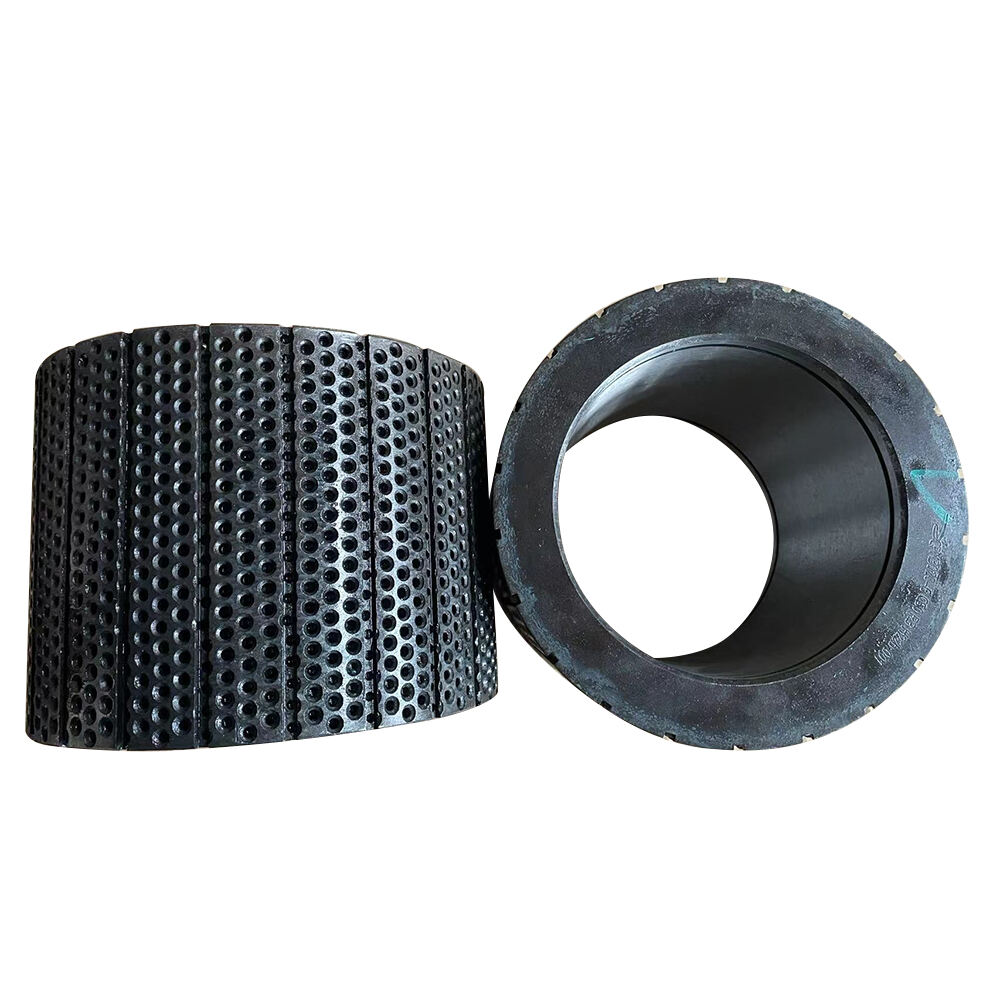

hammer mill beater wholesale

Hammer mill beater wholesale represents a crucial component in industrial grinding and crushing operations. These essential parts are designed to deliver consistent performance in size reduction applications across various industries. The beaters, manufactured from high-grade wear-resistant materials, function as the primary impact elements within hammer mills, efficiently breaking down materials through repeated striking actions. Each beater is precisely engineered to maintain optimal operational efficiency while ensuring extended service life. The wholesale distribution of these components provides cost-effective solutions for bulk buyers, manufacturers, and industrial facilities requiring regular replacements. Modern hammer mill beaters incorporate advanced metallurgical compositions that enhance their durability and resistance to abrasive wear. They are available in various specifications to accommodate different mill sizes and processing requirements, from fine grinding to coarse crushing applications. The wholesale market offers diverse options in terms of material composition, size configurations, and surface treatments, enabling customers to select products that best match their specific operational needs. These components are essential in processing industries including agriculture, mining, recycling, and biomass processing, where consistent material size reduction is crucial for downstream operations.