efficient hammer blade

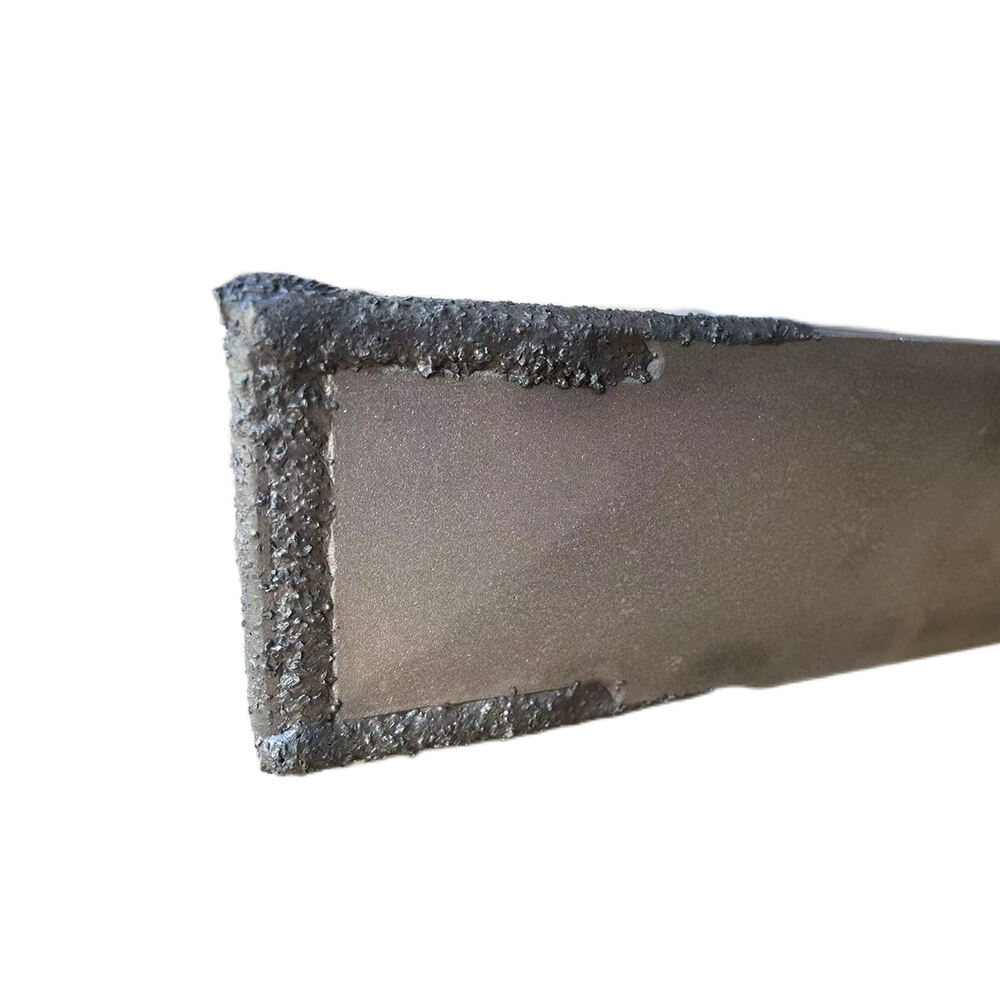

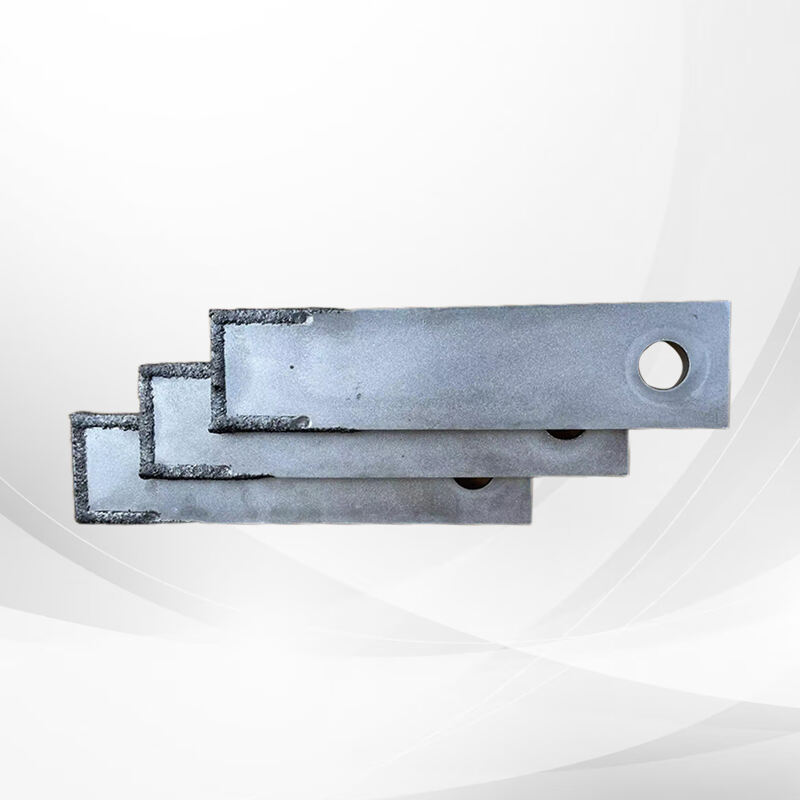

The efficient hammer blade represents a significant advancement in cutting technology, combining robust durability with precision engineering. This innovative tool features a high-carbon steel construction, professionally heat-treated to achieve optimal hardness and wear resistance. The blade's unique geometry incorporates advanced tooth design that enables superior cutting performance while minimizing material waste. Engineered with a specialized coating that reduces friction and prevents material adhesion, the efficient hammer blade maintains its cutting edge longer than traditional alternatives. Its versatile design allows for seamless integration with various hammer mill systems, making it ideal for multiple industrial applications, from wood processing to recycling operations. The blade's balanced construction ensures minimal vibration during operation, contributing to reduced wear on machinery and improved workplace safety. With precision-ground cutting edges and carefully calculated angles, these blades deliver consistent performance across different materials and operating conditions. The efficient hammer blade also features an innovative mounting system that facilitates quick replacement and maintenance, reducing downtime and increasing overall operational efficiency. These blades are manufactured under strict quality control standards, ensuring each unit meets exacting specifications for dimensional accuracy and material consistency.