rullu qablaça satılık

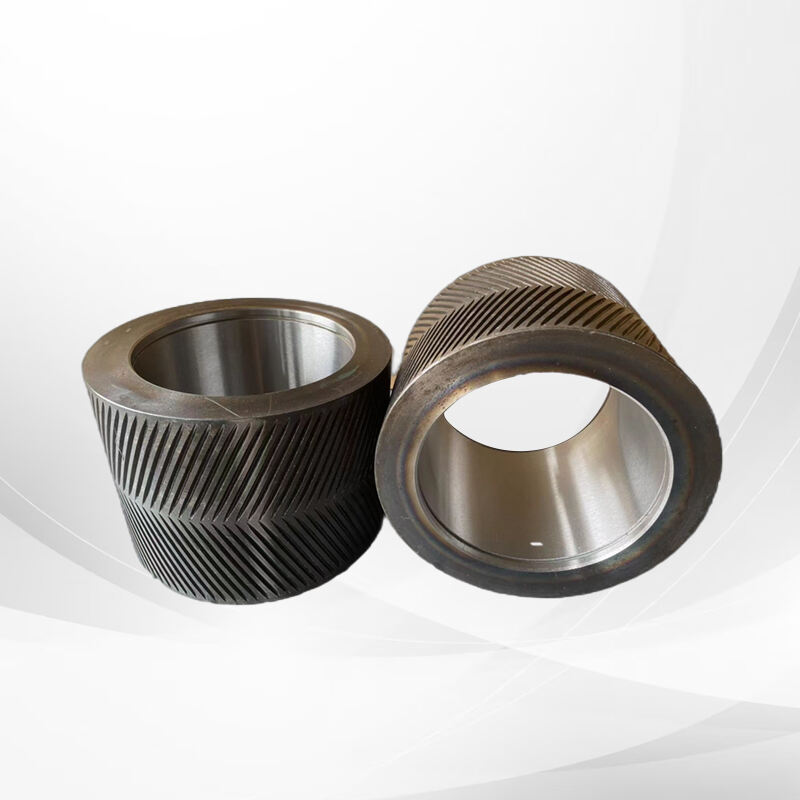

Satışdakı rol yer kabuğu, endüstriyal məşq dəstgahlarında əsas bir elementi təmsil edir və müxtəlif tətbiqlərdə istisna qaynarlıq və uzun ömürlülük göstərmək üçün hazırlanmışdır. Bu səhiyyəli ümumiləşdirilmiş silindriş formasında olan komponent, optimal xərclənənlik qarşısını və struktur integritetini tamamilə dəstəkləmək üçün güclü metallurgik tərkibə malikdir. Kabuğun səthi, ciddi ölçülərə uyğunluq saxlamaq üçün dəqiqliyə görə işlənmişdir, bu da tələbli endüstriyal ortamlarda yaxşı fırlanma və sabit performansı təmin edir. Fərqli ölçülərdə və spesifikasiyalarda mövcud olan bu rol yer kabuqları, müxtəlif yüklərə və işləmə şərtlərinə uyğunlaşır. İstehsal prosesi, kabuğun mexaniki xüsusiyyətlərini artıraraq və xidmət ömrünü uzataraq ən yeni istifadə olunan istilik işləmə texnikalarını daxil edir. Xüsusi xüsusiyyətləri arasında xərclənənlik qarşısını yaxşılaşdıran spesial səth işləmələri, tətbiq tələblərinə uyğunlaşdırılmış redaktə edilə bilən ölçülər və fərqli montaj sistemləri ilə uyğundur. Rol yer kabuğunun dizaynı, yüksək sürətli tətbiqlərdə rəddiyyət azaltmaq və stabillikli işləməni təmin etmək üçün eyni yüklənənlikda paylanmasını öncələkləndirir. Hər bir vahid, endüstri standartlarına və spesifikasiyalara uyğunluq təmin etmək üçün, ölçülərin təsdiq edilməsi və material sınamaları da daxil olmaqla, çox ciddi keyfiyyət idarəetmə prosedurlarından keçirilir.