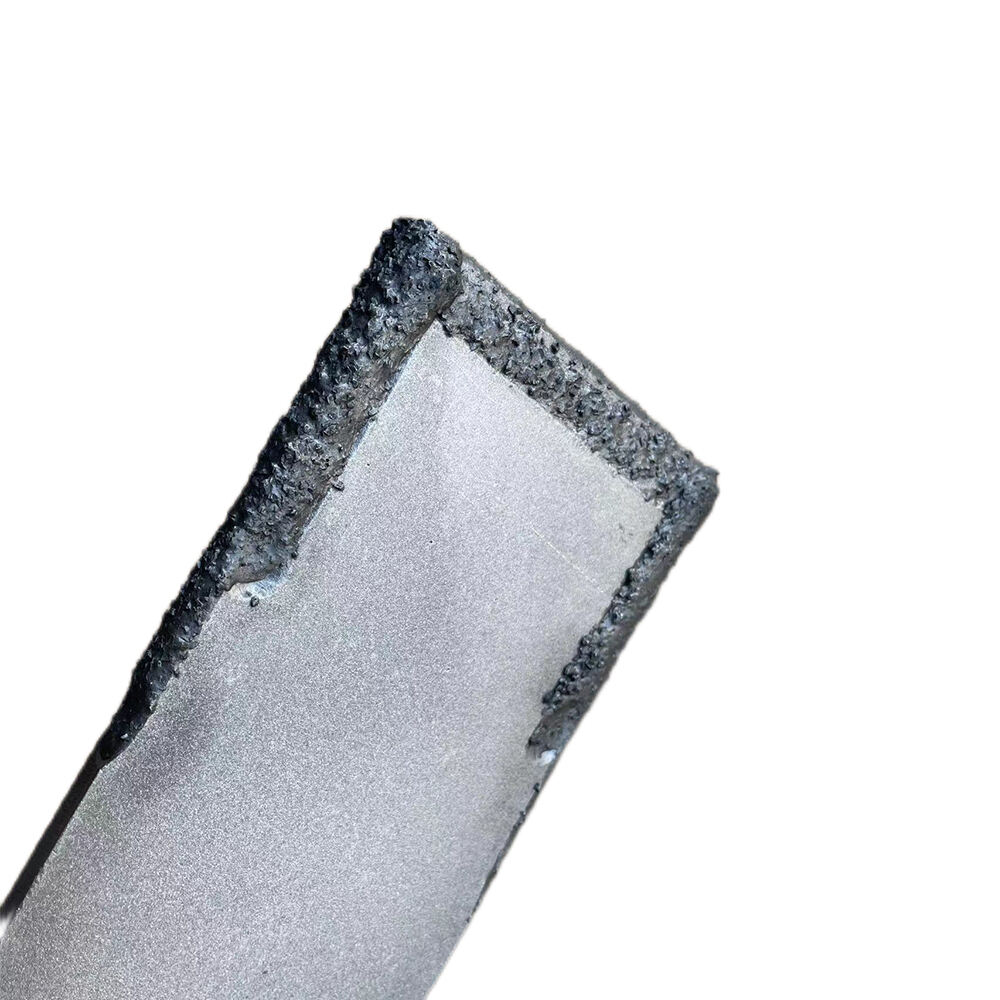

newest hammer blade

The newest hammer blade represents a significant advancement in cutting technology, combining the robust power of a hammer mechanism with precision blade engineering. This innovative tool features a high-carbon steel construction with a specialized coating that enhances durability and resistance to wear. The blade's unique serrated edge pattern incorporates advanced tooth geometry, optimizing cutting efficiency while minimizing material waste. At its core, the hammer blade utilizes a revolutionary impact-absorption system that reduces vibration by up to 70% compared to traditional models, making it significantly more comfortable for extended use. The blade's design includes an integrated quick-release mechanism for rapid blade changes, enhancing productivity in professional settings. With a cutting depth of up to 4 inches and variable speed settings ranging from 1000 to 3000 RPM, this versatile tool excels in both aggressive cutting tasks and precision work. The hammer blade's advanced thermal management system prevents overheating during continuous operation, while its electronic feedback system maintains consistent cutting speed under varying loads.