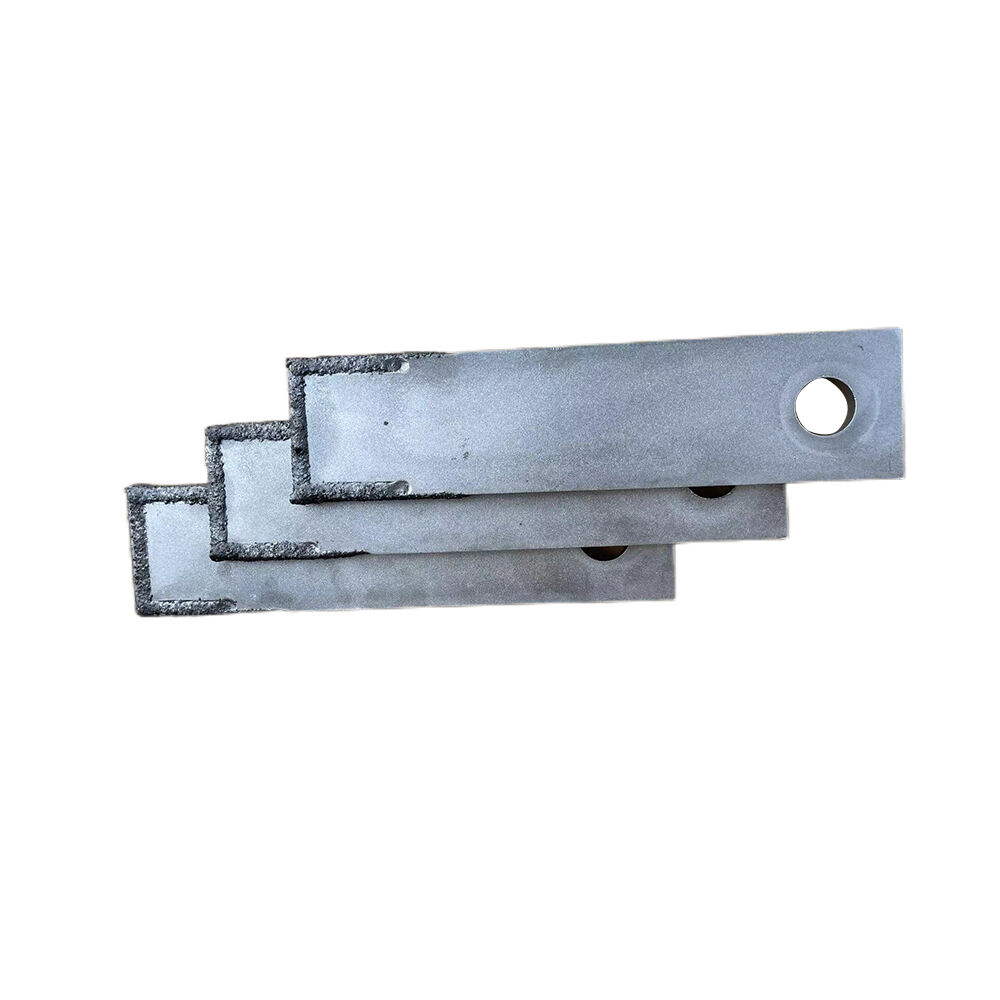

customized hammers

Customized hammers represent a significant advancement in precision tooling, offering users unparalleled versatility and efficiency in various applications. These specialized tools are engineered with state-of-the-art materials and manufacturing processes to meet specific requirements across industries. Each hammer features carefully calibrated weight distribution, ergonomically designed handles, and specialized head compositions tailored to unique applications. The customization options include variable head weights, multiple striking face designs, and interchangeable handle materials, allowing users to optimize their tool for specific tasks. Advanced vibration dampening technology integrated into the handle design reduces user fatigue and increases working comfort, while precision-machined striking surfaces ensure consistent impact delivery. These hammers incorporate innovative features such as magnetic nail starters, replaceable striking faces, and laser-etched measurement guides, enhancing functionality and user convenience. The tools undergo rigorous quality control processes, including impact testing and material stress analysis, ensuring durability and reliable performance across their intended applications. Whether for specialized industrial use, precise craftwork, or professional construction applications, these customized hammers deliver exceptional performance through their thoughtful design and superior build quality.